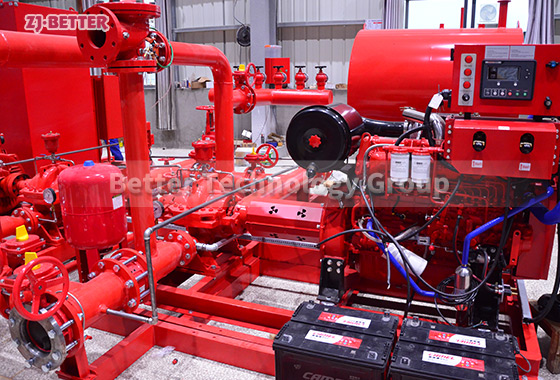

EDJ Double Suction Fire Pump Set

Advantages of OTS fire pump set:

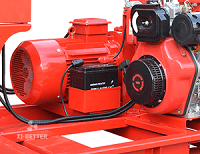

1. Advanced hydraulic model, high efficiency and wide performance range.

2. Horizontal structure, easy installation and maintenance, small footprint.

3. Small vibration and low noise. Hydraulic balance of axial force is adopted to make the pump run smoothly, safely and reliably.

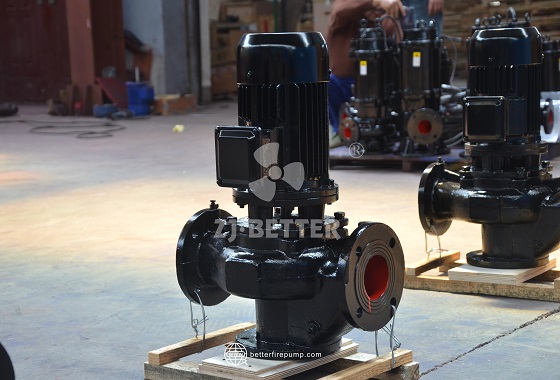

4. The inlet and outlet of the pump are on the same horizontal axis, which is convenient for pipeline connection and extremely convenient for loading and unloading.

Applicable occasions for double suction fire pump: fire water supply in residences, hotels, office buildings, commercial buildings, factories, hospitals, etc.

Under normal circumstances, as long as any flow and pressure working point is selected within the performance range of the horizontal double-suction fire pump, the appropriate model can be provided to meet user needs. In the process of using the fire pump, it is also necessary to pay attention not to exceed the rated performance of the selected model. During operation, the bearing temperature should not exceed the ambient temperature of 35 degrees, and the higher temperature should not exceed 80 degrees. The junction table between the horizontal pump and the pipeline should ensure good air tightness, especially the water inlet pipeline, which must be strictly air-tight, and there should be no possibility of air trapping on the device.