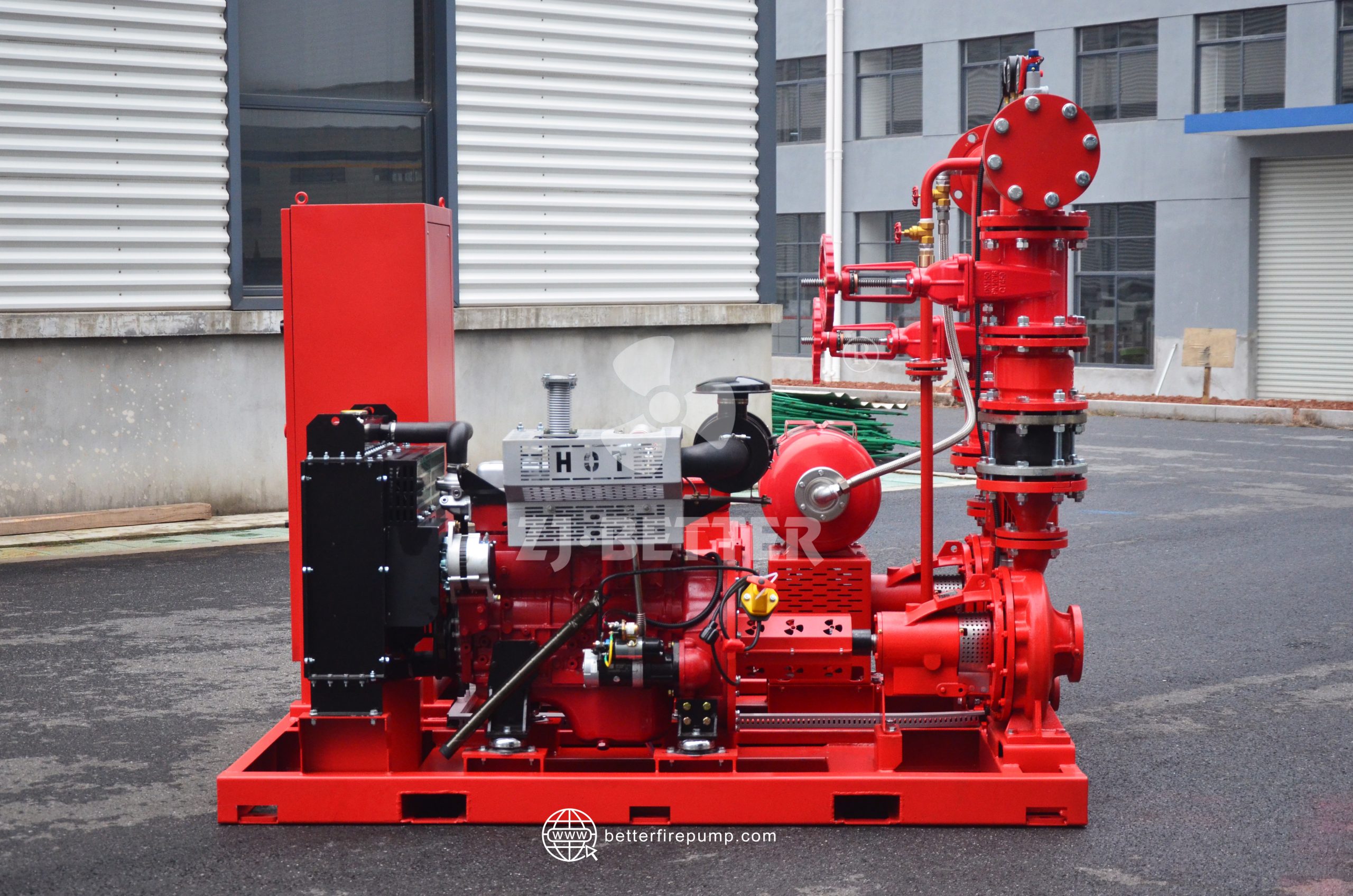

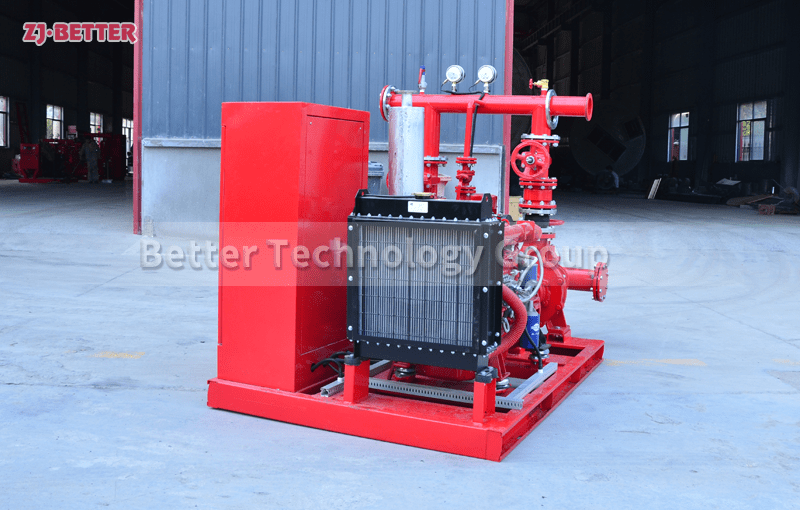

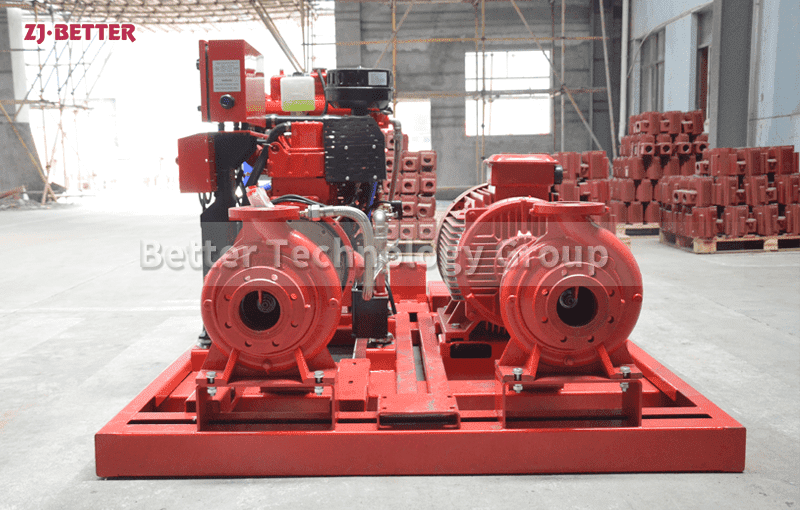

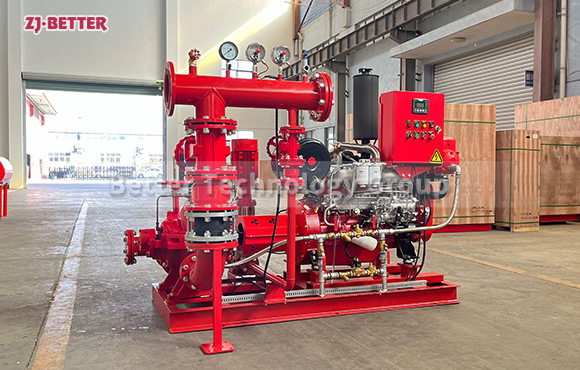

Skid-Mounted Diesel Fire Pump Unit for Fast Installation and Efficient Fire Response

Skid-mounted diesel fire pump units integrate diesel power, high-efficiency centrifugal pumps, and intelligent control systems. They offer advantages such as emergency start-up in the event of a power outage, rapid installation, stable operation, and convenient maintenance. They are suitable for industrial plants, warehousing and logistics, municipal and emergency fire water supply systems.

Skid-mounted diesel fire pump units are high-reliability water supply equipment specifically designed for emergency fire protection systems. The integrated skid-mounted structure highly integrates the diesel engine, fire pump, control system, piping components, pressure stabilization, and protection devices onto a single steel base, enabling rapid on-site deployment and commissioning. It is particularly suitable for industrial, commercial, and municipal fire protection scenarios with extremely high requirements for response speed and system stability. The core advantage of this type of equipment lies first in the independence of its power system. Using a diesel engine as the drive source, it can maintain stable operation even in the event of a power outage, natural disaster, or sudden accident that paralyzes the power supply system, continuously providing the necessary pressure and flow to the fire protection system and avoiding the risk of fire suppression system failure due to power problems. The diesel engine is specially designed for fire protection conditions, featuring rapid start-up, strong low-temperature adaptability, and ample torque reserve. It can complete automatic or manual start-up in a short time, ensuring an effective water supply can be established in the early stages of a fire. The fire pump section typically utilizes a high-efficiency centrifugal pump structure, combined with an optimized hydraulic model and wear- and corrosion-resistant materials. This ensures stable performance output even under high head and high flow conditions, with low vibration and noise during long-term operation, meeting the stringent requirements of fire codes regarding continuous operating time and performance degradation. The skid-mounted structure is another significant advantage. Compared to traditional split-type fire pump room installations, this unit is pre-assembled, commissioned, and tested at the factory. On-site work only requires foundation placement, inlet and outlet pipe connections, and simple electrical connections, significantly shortening the construction cycle, reducing on-site installation errors, and improving system delivery efficiency. This is particularly suitable for projects with tight schedules or renovation projects. The integrated base is welded from high-strength steel, providing a stable structure and strong load-bearing capacity. It effectively absorbs vibrations generated during equipment operation, extending the overall service life of the unit. It also facilitates overall hoisting and transportation, adapting to different project logistics and site conditions. In terms of control systems, skid-mounted diesel fire pump units are typically equipped with dedicated fire control cabinets, supporting automatic, manual, and remote control modes. They can monitor diesel engine speed, oil pressure, water temperature, cooling status, and changes in fire pump outlet pressure and flow in real time. In abnormal operating conditions, they can issue audible and visual alarms or execute protective shutdowns to ensure the equipment always operates within a safe range. The control system logic is optimized for fire protection applications, enabling automatic start-up and switching when a fire signal is triggered or pipeline pressure drops, avoiding delays caused by human intervention and significantly improving the reliability and response speed of the overall fire protection system. To meet the needs of different application scenarios, skid-mounted diesel fire pump units offer high flexibility in piping configuration. They can integrate suction pipes, discharge pipes, bypass pipes, pressure relief pipes, and necessary valves and instruments according to project requirements, ensuring seamless integration with existing fire protection pipelines while facilitating daily inspection and maintenance. The appropriate configuration of pressure stabilizing and buffering devices effectively reduces start-up and shutdown shocks, maintains stable pipeline pressure, and extends the service life of valves and piping systems. In terms of materials and manufacturing processes, key components of this type of equipment are mostly made of corrosion-resistant cast iron, stainless steel, or high-strength alloy materials, enabling them to adapt to different water quality conditions and complex environments. The surfaces undergo rust and corrosion prevention treatment, maintaining good structural strength and appearance even during long-term operation in humid, dusty, or high-temperature environments. The diesel engine cooling system is optimized, combining a high-efficiency radiator and a reasonable air duct layout to maintain a stable temperature even under continuous high-load operation, preventing power reduction or malfunctions due to overheating. From an application perspective, skid-mounted diesel fire pump units are widely applicable to industrial plants, petrochemical facilities, logistics and warehousing centers, commercial complexes, data centers, tunnel projects, and municipal emergency fire protection systems. Their independent power supply and rapid deployment advantages are particularly prominent in projects far from the power grid or with extremely high power supply reliability requirements. For scenarios requiring temporary or mobile fire protection, the skid-mounted design also facilitates transfer between different projects, improving equipment utilization and reducing overall investment costs. In terms of maintenance and use, this product was designed with ease of daily maintenance in mind from the outset. Key maintenance points are rationally laid out, and routine inspections and maintenance operations do not require complex disassembly. Clear labeling and monitoring instruments help maintenance personnel quickly grasp the equipment status, reducing maintenance difficulty and downtime. Overall, the skid-mounted diesel fire pump unit, through its efficient power system, stable and reliable hydraulic performance, integrated quick-installation structure, and intelligent control and protection design, achieves the goals of rapid installation and efficient fire response. It is an ideal choice for modern fire protection systems, balancing safety, reliability, and economy, providing a solid guarantee for life and property safety in critical moments.