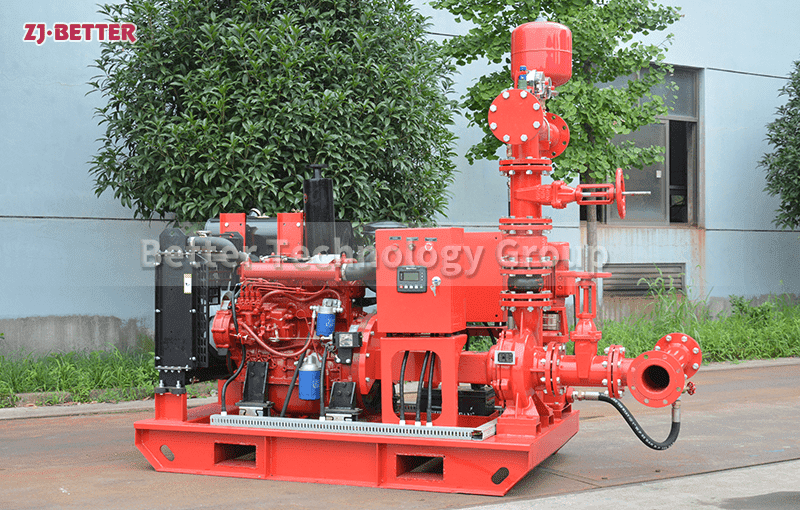

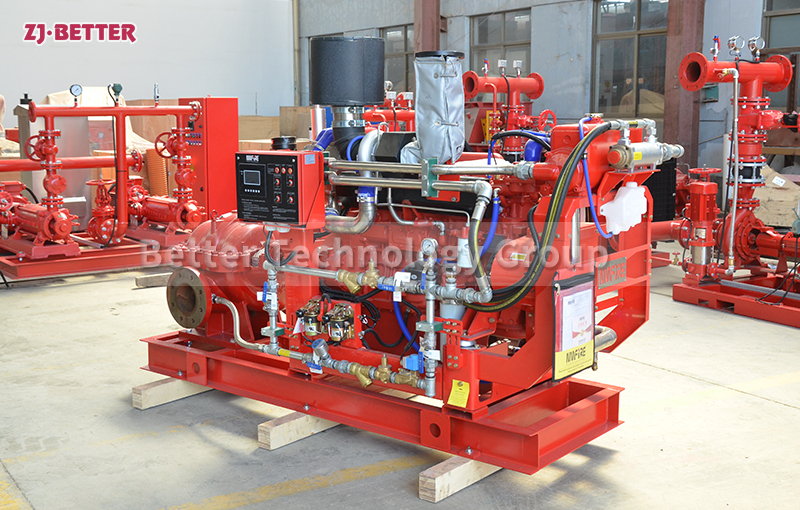

Diesel Multistage Pump

Features of diesel multi-stage pump:

1. Multiple impellers are combined in series, the output pressure is large, so the lift is high.

2. The shaft seal adopts packing seal or mechanical seal, the seal is safe and reliable, the structure is simple, and the maintenance is convenient and quick.

3. The shaft is a fully sealed structure, which ensures no contact with the medium, no rust, and long service life.

Diesel engine multi-stage pump is composed of diesel engine and multi-stage pump. The pump group is in the form of horizontal, single-suction, multi-stage, and segmented centrifugal pumps. It has high efficiency, wide performance range, safe and stable operation, low noise, long life, Easy to install and maintain. This diesel engine multi-stage pump can be used to transport clean water or other liquids with physical and chemical properties similar to water. It can also be used to transport hot water, oil, corrosive or abrasive materials by changing the material of the pump flow parts, sealing form and adding a cooling system. particle medium.