Quiet and Efficient Inline Fire Pump Set for Faster Fire Protection Response in Buildings

The high-efficiency silent pipeline fire pump set has a compact structure, flexible installation and quick response, and is suitable for the stable water supply and space saving needs of building fire protection systems.

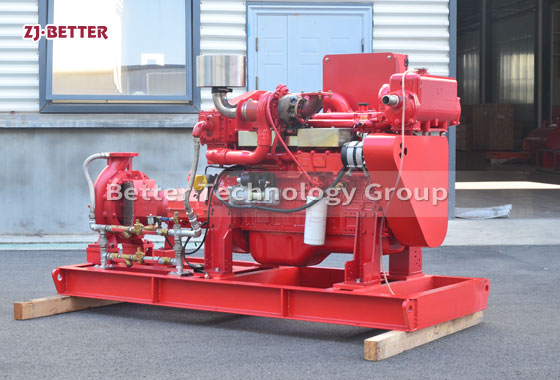

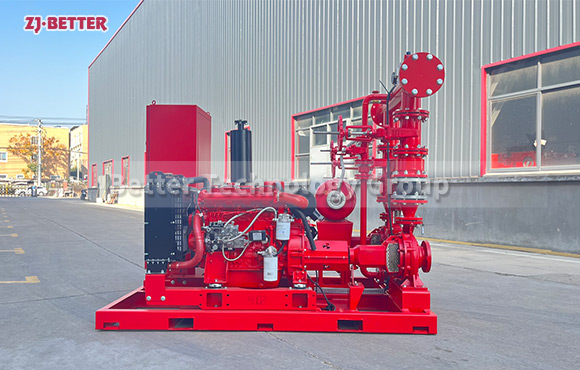

The efficient and silent pipeline fire pump group is a fire water supply equipment with compact structure, stable operation and rapid response. It is widely used in high-rise residential buildings, commercial buildings, office buildings, underground garages, hospitals, schools, shopping malls and other construction projects that require stable fire water supply but limited space. Compared with traditional large-scale horizontal fire pumps, this type of vertical pipeline pump equipment greatly compresses the installation area and optimizes the system layout without sacrificing performance, and shows many advantages such as high efficiency, low noise and easy maintenance in actual operation. The equipment is usually composed of a vertical single-stage centrifugal pump, stainless steel pipes, flange connection devices, automatic air release devices, electric control systems, voltage stabilization systems, pressure gauges, control buttons and alarm display systems, and all are installed on an integrated base. Through the design of an integrated structure, users can achieve “put and use” during installation and use without complex assembly or additional debugging. It is particularly suitable for renovation projects or new projects that have strict requirements on the compactness of the fire pump layout.

From the performance point of view, the core power of the pipeline fire pump comes from the high-efficiency and energy-saving vertical motor, which is coaxially connected to the pump body and has an axial vertical design, making the equipment stable and consuming less energy. The pump body is made of high-quality cast iron or stainless steel, and the internal hydraulic balance structure is designed to effectively reduce the axial thrust, mechanical wear and noise during operation. The flow range of the pump generally covers 20m³/h to 200m³/h, and the head can reach 20 meters to more than 100 meters, which is suitable for the water supply needs of different building fire protection systems. At the same time, since the inlet and outlet are on the same axis, the equipment can be directly installed on the pipeline without the need for additional anchor bolts or concrete foundations, which greatly reduces the construction volume and system pressure loss, and improves the overall system hydraulic efficiency. The pump group supports power frequency starting or variable frequency starting. While maintaining the rated working pressure, it avoids current shock caused by frequent start and stop, and prolongs the service life of the motor. It is an effective support for the high-frequency standby and instantaneous response requirements of the building fire protection system.

The intelligent control system equipped with this equipment is a highlight. It includes three control modes: manual start, automatic start, and linkage start. It can receive start-up instructions from signal sources such as the fire control center, alarm detectors, and water flow indicators. After receiving the fire signal, it automatically starts the pump group to supply water and quickly responds to the initial fire extinguishing needs. The control panel has operation status indication, pressure display, voltage and current monitoring, fault alarm, self-test functions, etc., which can grasp the operation of the equipment in real time and warn of system abnormalities in time. Some equipment also supports remote monitoring functions, accessing the building fire management platform through RS485 or 4G modules to achieve cross-regional supervision, data synchronization and maintenance scheduling, and effectively improve the intelligence and automation level of fire pump operation and maintenance. In order to ensure the stability of water pressure, the system has a built-in small pressure-stabilizing pump or pressure-stabilizing tank component, which can maintain the water pressure of the pipeline network within the preset range when the main pump is not started, avoiding problems such as false alarms and water spraying lag, and improving the reliability and timeliness of the entire building fire protection system.

In terms of noise control, the design of the pipeline fire pump fully considers the demand for low-noise operation in building scenarios. The equipment itself uses a low-speed motor, which makes less noise during operation; the pump body and the motor are connected by thickened shock-absorbing pads, and shock-absorbing rubber blocks are set between the installation base and the ground to effectively absorb the vibration and noise generated during operation. It is suitable for noise-sensitive use environments such as office areas, hospital wards, and residential buildings. For projects installed in underground pump rooms or narrow spaces, the operating noise can be further reduced by matching silencers, soundproof doors, etc., so that the fire protection system does not interfere with daily life and work order while ensuring safety, reflecting the precise response of modern buildings to the dual needs of “quiet and safe”.

In addition, the installation and maintenance of the equipment are also very convenient. Since the inlet and outlet are on the same horizontal axis, the whole machine can be directly inserted into the original fire protection pipe network system of the building, reducing the length of the pipe and the number of joints, and shortening the installation period. The integrated base structure is easy to carry as a whole, suitable for transportation in narrow spaces such as elevators and underground passages. The equipment occupies a small area and can be flexibly arranged in space-restricted areas such as pump rooms, stairwells, and underground machine rooms. Inspection ports and sewage outlets are reserved on the pump body to facilitate regular cleaning, lubrication, and maintenance by technicians. Some models support quick-detachable motor and impeller assemblies, and there is no need to disassemble the entire machine during maintenance, saving downtime and improving operation and maintenance efficiency. In daily use, the system can also simulate startup and shutdown through a timed self-check program to ensure that the equipment is in a good standby state for a long time. When a real fire occurs, it can “start with a press of a button and continue to supply water”, truly ensuring technical safety and performance to protect life.

From the perspective of energy conservation and environmental protection, this type of pump group focuses on the overall energy efficiency level during the design stage. The motor part meets the national energy-saving standards or IEC high-efficiency motor grade certification, with a high power factor and an efficiency of more than 90%. On the premise of meeting the peak flow rate, the motor speed can also be controlled by the frequency converter, and the flow and head can be adjusted according to the actual water demand to avoid unnecessary energy waste. At the same time, the equipment has no exhaust gas emissions and oil leakage during operation, and does not pollute the surrounding environment. It can be deployed in poorly ventilated and air-tight places for a long time without causing additional harm, meeting the green building standards and the construction requirements of modern energy-saving fire protection systems.

In summary, the efficient and silent pipeline fire pump group is an integrated fire water supply equipment designed for modern building fire scenes. It has multiple advantages such as stable operation, rapid response, intelligent control, energy saving and environmental protection, convenient installation, and low noise. It can significantly improve the actual response speed and overall safety level of the building fire protection system. While improving the water supply capacity in the early stage of fire extinguishing, it also saves valuable space for the project and reduces the pressure of operation and maintenance. It is an important choice for small and medium-sized buildings, high-rise residential buildings, commercial office buildings and other places to achieve efficient, reliable and safe fire water supply. As urban buildings develop in the direction of intensive and intelligent development, higher standards are also proposed for fire protection systems. This type of pump group products with reasonable structure, efficient operation and advanced technology will play an important role in more scenarios and become an important part of the modern building fire safety system.