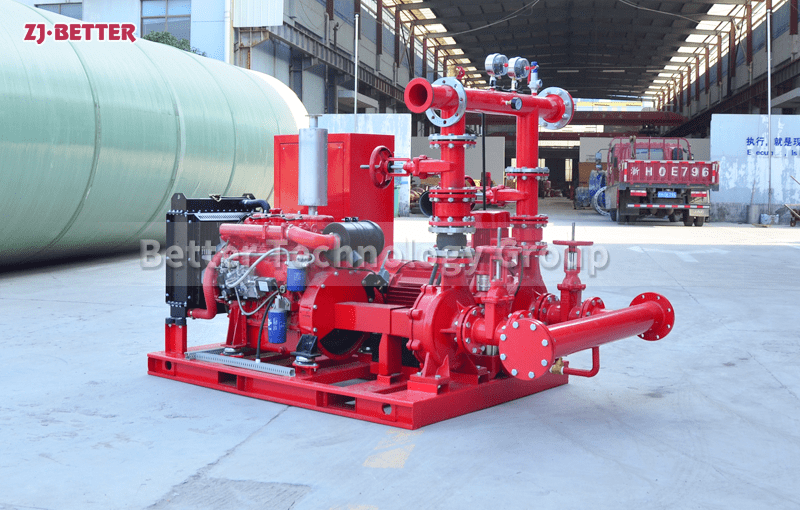

Single-Stage Horizontal Centrifugal Diesel Fire Pump Complying with UL/FM Standards

High-performance single-stage horizontal centrifugal diesel fire pump engineered to meet UL/FM standards. Delivers reliable, efficient fire protection with strong pressure output, ideal for critical facilities and remote installations.

The single-stage horizontal centrifugal diesel fire pump designed to meet UL and FM standards represents a high-performance, highly reliable, and durable solution for fire protection systems in industrial, commercial, municipal, and residential infrastructures. This type of fire pump is engineered with a focus on delivering superior hydraulic performance, robust structural design, and compliance with the most stringent international safety and quality certifications. Driven by a high-torque diesel engine, it ensures uninterrupted water delivery in emergency scenarios where electricity supply may be compromised. The pump’s horizontal configuration not only optimizes installation and maintenance convenience but also significantly improves system stability during operation. The volute casing is precision cast from ductile iron or stainless steel depending on the required application, ensuring exceptional corrosion resistance and strength. The impeller, dynamically balanced and hydraulically optimized, is made from bronze or stainless steel, offering high-efficiency water movement with reduced hydraulic losses. The shaft is crafted from high-strength stainless steel and designed for minimal deflection and vibration, extending bearing life and maintaining sealing integrity. This configuration allows the unit to operate under high pressures with consistent flow, meeting or exceeding performance curves outlined by UL and FM specifications. The diesel engine is selected from internationally recognized manufacturers and tested rigorously for durability, fuel efficiency, and ease of integration with fire control systems. It includes a battery-powered electric start, water cooling system, fuel tank, muffler, and an automatic shutdown feature in case of high temperature, low oil pressure, or overspeed conditions. A heavy-duty steel baseplate with anti-vibration mounts anchors the entire assembly, minimizing structural resonance and protecting critical pump components during prolonged use. The coupling between the diesel engine and the pump adopts a flexible shaft alignment system that prevents mechanical stress transfer and reduces the chance of misalignment-related wear. The system integrates a complete set of sensors, controllers, and alarm modules that continuously monitor engine status, pump discharge pressure, flow rate, and system faults, ensuring real-time response and diagnostics. The control panel, designed with intuitive interfaces and digital indicators, provides automatic start/stop capability based on system pressure feedback, while also offering manual override and emergency stop functionality. With advanced safety features, such as non-return valves, pressure relief valves, and pressure gauges at both suction and discharge sides, this pump ensures seamless operation under all fire-fighting conditions. All components are factory-assembled, performance-tested, and aligned before delivery to ensure plug-and-play readiness at the installation site. Additionally, the system can be customized to include jockey pumps, pressure maintenance units, priming tanks, and remote monitoring systems, providing a comprehensive fire protection solution tailored to specific site requirements. One of the key advantages of this pump is its exceptional efficiency curve, maintaining consistent output across a wide range of flow demands, which ensures minimal energy loss and effective firefighting capability even in the most demanding environments. Furthermore, its ability to operate independently of electrical power makes it an ideal solution for remote facilities, critical infrastructure, oil refineries, power plants, and any high-risk location where fire suppression is mission-critical. The durability of all wet-end components ensures extended service life, with minimal maintenance cycles and predictable service intervals, thereby reducing long-term operational costs and increasing reliability. In terms of compliance, every pump undergoes hydrostatic testing, performance testing, and vibration analysis in accordance with UL448 and FM1333 standards, ensuring full traceability and adherence to international fire safety codes. Documentation provided includes performance curves, material traceability reports, diesel engine certifications, and factory inspection results. Installation can be performed on concrete foundations or skid-mounted platforms depending on site conditions, with the system designed for quick integration into existing piping layouts using flanged connections. In applications such as warehouses, hospitals, commercial complexes, airports, and petrochemical storage facilities, this diesel fire pump plays a crucial role in safeguarding assets and lives by delivering pressurized water supply to sprinklers, hydrants, and deluge systems with high responsiveness. The combination of rugged engineering, operational independence, and code compliance makes it one of the most trusted fire pump solutions in the global safety and protection industry. Whether deployed as a standalone unit or integrated into a complete fire pump package including electric and jockey pumps, its performance, reliability, and ease of use make it the preferred choice for engineers, consultants, and contractors worldwide. Its modular design allows for easy upgrades, retrofits, or maintenance procedures without requiring significant downtime or system reengineering. Moreover, with available options for weatherproof enclosures, sound attenuation, and tropical climate adaptation, this diesel fire pump can be deployed in a wide range of environmental conditions while maintaining optimal operational parameters. It meets seismic anchoring requirements and can be provided with vibration isolators and flexible joints to accommodate building movement. The system’s adaptability, compliance, and reliability are key factors driving its popularity in global firefighting infrastructure, especially in regions where dependable power sources are not guaranteed. With over thousands of units installed globally, this horizontal centrifugal diesel fire pump remains an integral part of fire protection designs that demand ruggedness, responsiveness, and resilience. In conclusion, the single-stage horizontal centrifugal diesel fire pump is not just a fire suppression device; it is a critical safety asset engineered for performance, reliability, and durability in real-world emergency scenarios.