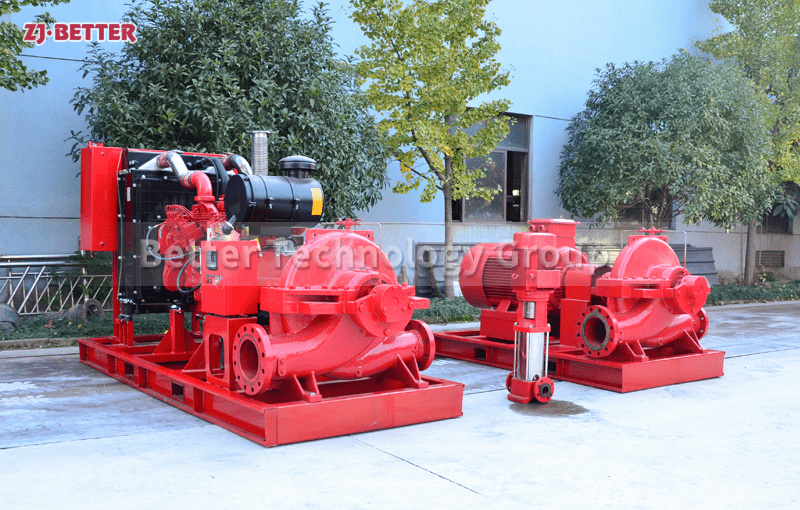

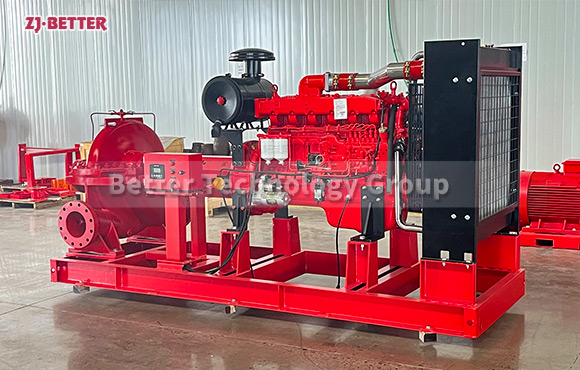

Motor-Driven Fire Pump Package: Lower Energy Consumption, Enhanced Fire Suppression Efficiency

Discover the advantages of an electric-driven integrated fire pump system, offering high efficiency, stable pressure, intelligent control, and space-saving design for reliable fire protection in commercial, industrial, and high-rise buildings.

As a crucial component of modern building fire protection systems, motor-driven integrated fire pumps can quickly start up in the early stages of a fire and provide a stable and reliable high-pressure water source, effectively controlling the spread of fire and ensuring the safety of personnel and property. This equipment utilizes a high-efficiency motor as its core drive, combined with an advanced hydraulically designed pump structure, ensuring superior performance in a variety of firefighting applications. The integrated design offers a compact footprint and easy installation, making it particularly suitable for compact or space-constrained areas in a variety of scenarios, such as high-rise buildings, underground facilities, industrial plants, and commercial complexes. The equipment’s key advantages lie in its low energy consumption, fast response, and stable operation, enabling efficient 24/7 standby operation and truly “on-demand” automated control. Its motor, manufactured to international standards for high efficiency, combines low noise levels with high insulation performance to maintain a low temperature rise and long lifespan even under continuous high-load operation. Furthermore, the accompanying control cabinet system utilizes an intelligent PLC programmable controller or industrial-grade electrical components, enabling multiple functions such as automatic start and stop, remote control, fault self-diagnosis, and real-time operating status feedback, greatly enhancing its management convenience and operational safety. The entire system is equipped with key components such as a pressure-stabilizing tank, a shock-absorbing base, a one-way valve, and a pressure gauge. These components can stabilize the water pressure, buffer the water hammer effect, prevent backflow from affecting the life of the pump body, and demonstrate strong adaptability when dealing with sudden pressure fluctuations. In terms of energy efficiency, this all-in-one electric fire pump fully embodies the concept of energy conservation. Its power matching is precise, and it can achieve the optimal operating point according to the actual pipe network pressure and flow requirements, avoiding the waste of power or frequent startups in traditional systems. In terms of structure, the overall frame is made of high-strength carbon steel or stainless steel sprayed with anti-corrosion treatment, which can adapt to various corrosive environments such as high humidity and high salt spray. The pump body is mostly made of high-precision cast iron or stainless steel to ensure both mechanical strength and anti-rust performance. In terms of sealing performance, the pump shaft adopts a highly wear-resistant mechanical seal, which can withstand the erosion of medium impurities during long-term operation without leakage, ensuring the long-term and stable operation of the system. This type of product typically features automatic dual power switching, connecting to both the primary power source and a backup generator set. In the event of a utility power outage, it automatically switches to the backup power source to maintain operation, ensuring uninterrupted water supply to the fire protection system. This is a crucial technical support for implementing the “zero-tolerance fire” strategy in critical locations. Furthermore, the motor-driven integrated pump unit boasts a well-designed structural layout, with all interfaces and maintenance points easily accessible and visible, facilitating daily inspection and maintenance. The electronic control system utilizes a human-machine interface (HMI) display, providing intuitive access to operating data, parameter settings, and fault alarm information, enabling operators to instantly understand and respond to system health. In terms of compliance, this type of equipment generally meets or exceeds international and industry fire protection standards such as NFPA 20, GB 27898, and EN 12845, making it the preferred configuration for many design institutes and engineering firms during the design and construction phases of fire protection systems. Its application is extensive, encompassing key fire protection areas such as airports, rail transit, power facilities, oil depots and warehouses, and chemical plants. With the development of smart fire protection, these products are gradually gaining the ability to connect to smart city IoT platforms. They can upload device status via various communication protocols such as RS485, Modbus, and TCP/IP, enabling remote centralized monitoring, early warning, and operation and maintenance management, further enhancing the intelligence and response efficiency of the entire fire protection system. Overall, motor-driven integrated fire pumps, with their multiple advantages such as high performance, low failure rates, strong adaptability, and easy maintenance, have become core equipment in contemporary high-standard fire protection projects. They not only enhance fire emergency response capabilities but also drive the entire fire protection industry towards automation, intelligence, and green energy conservation. Choosing an electric integrated fire pump is a wise choice for building a reliable, economical, and efficient fire water supply system.