Robust Structure and Easy Maintenance: Engineering Design Advantages of Horizontal Fire Pump Units

This highly efficient horizontal centrifugal electric fire pump boasts powerful water supply capacity and stable operation, a compact design, and easy installation. It’s suitable for fire protection systems in high-rise buildings, industrial facilities, and large public spaces. Its energy-saving design and reliable control system ensure stable water pressure at critical moments, providing a solid foundation for safety and protection.

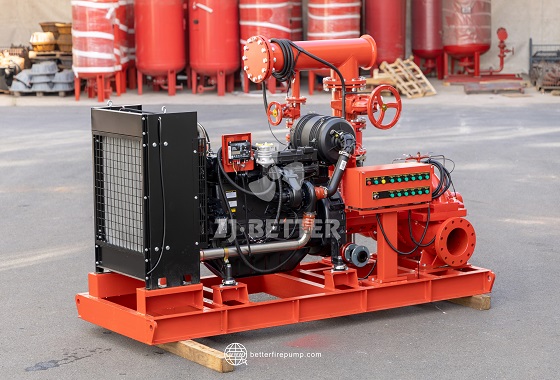

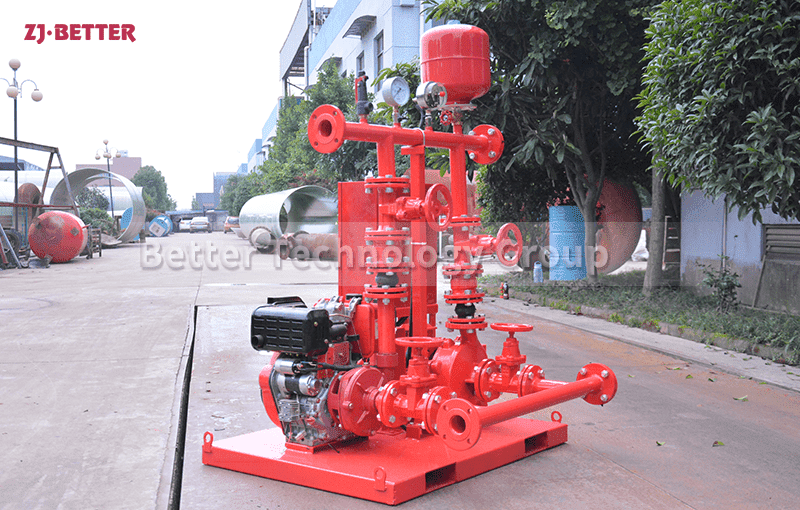

In modern fire water supply systems, the stability, reliability, and maintainability of fire pumps are crucial performance indicators. With the increasing scale of buildings and complexity of industrial environments, traditional pump sets often struggle to balance high-intensity operation with easy maintenance. Horizontal fire pump sets, with their robust structural design, rational mechanical layout, and convenient maintenance, are an ideal choice for widespread use in various locations. The rigorous conditions of emergency water supply are carefully considered during the development and manufacturing of these equipment. Not only do they maintain high efficiency and stability under high-intensity operating conditions, but optimized engineering design also reduces maintenance complexity, thereby comprehensively extending their service life and safety. The primary advantage of horizontal fire pump sets lies in their robust structure. These units typically utilize a double-suction centrifugal design. The pump body is cast in a high-strength casting, offering exceptional pressure and shock resistance, enabling them to meet the demands of high-lift and high-flow water supply. The precision-matched pump shaft and bearing structure ensure smooth operation over extended periods, preventing performance degradation due to vibration or misalignment. Furthermore, its horizontal layout ensures a more stable center of gravity during installation, making it less susceptible to displacement or deformation due to operational shock. This stable mechanical property provides a strong safeguard for fire protection systems during critical moments. Compared to vertical pumps, horizontal pumps offer more balanced axial load distribution and relatively low overall mechanical losses. This not only extends service life but also ensures the equipment remains stable under prolonged, high-load conditions. Secondly, horizontal fire pumps excel in ease of maintenance. The pump body typically features a split-case design, allowing inspection and replacement of key components such as the impeller, shaft seal, and bearings by removing the upper pump cover without moving the motor or pump body, significantly reducing maintenance time and labor costs. During routine inspections, operators can quickly access vulnerable parts, making maintenance more efficient. This design is particularly suitable for locations requiring high long-term operational availability, such as large commercial complexes, industrial plants, or urban infrastructure. Maintenance can be completed without disrupting overall operations, ensuring continuous water supply. The pump unit’s design also fully considers sealing and cooling requirements. The shaft sealing system primarily utilizes mechanical seals or packing seals, ensuring zero or extremely low leakage even in high-pressure, high-flow environments, thereby preventing secondary damage or efficiency loss. The pump shaft cooling system, through optimized fluid circulation, effectively reduces component wear caused by high-temperature operation, extending equipment life and reducing maintenance frequency. In addition to its robust structure and ease of maintenance, the horizontal fire pump unit also boasts remarkable performance. Its double-suction impeller achieves higher flow output while maintaining stable hydraulic efficiency under the same conditions, making it suitable for meeting the water demands of large-scale buildings and industrial facilities. The hydraulically optimized flow path design within the pump body reduces flow losses and energy consumption, enabling the unit to maintain high efficiency over extended operation and lowering overall energy costs. Furthermore, the pump unit’s design balances high head and high flow, ensuring rapid delivery of sufficient water pressure and volume in emergencies such as fires, meeting the diverse needs of sprinkler systems, fire hydrant systems, and elevated water tanks. Engineered design concepts permeate every detail of the horizontal fire pump unit. To adapt to installation requirements in diverse locations, the pump unit’s foundation typically utilizes a high-strength steel welded or cast base, which not only enhances overall seismic resistance but also facilitates secure installation in varying surface conditions. For outdoor or high-humidity environments, the pump body and motor are treated with an anti-corrosion coating to further enhance durability. This comprehensive protection design enables the pump unit to operate stably and reliably in a variety of harsh environments, maintaining reliable performance in high and low temperatures, as well as high humidity. Regarding safety, the horizontal fire pump unit has undergone rigorous testing standards and engineering validation to ensure normal startup and stable water supply even in extreme conditions. Its automatic control and linkage system responds quickly to fire alarms, ensuring the pump unit is operational within seconds, saving valuable time during initial firefighting efforts. Furthermore, the pump unit supports a variety of drive options, including electric and diesel engines, creating a multi-layered safety mechanism. Even in the event of a power outage, the backup drive ensures uninterrupted water supply, comprehensively enhancing emergency response capabilities. It is worth noting that energy conservation and environmental protection were also emphasized during the design of the horizontal fire pump unit. By optimizing hydraulic design and improving component efficiency, the pump unit significantly reduces energy consumption while operating efficiently, lowering long-term operating costs and reducing carbon emissions, in line with the development trend of modern green buildings and industry. Furthermore, the equipment operates quietly, providing a more comfortable environment for users, which is particularly important in noise-sensitive areas such as hospitals and schools. Overall, the horizontal fire pump unit, with its robust structure, convenient maintenance, and excellent performance, fully demonstrates the advantages of engineered design. It not only provides a stable and reliable emergency water supply for various locations, but also reduces maintenance costs and improves operational efficiency through optimized design, meeting the multiple safety, reliability, and sustainability requirements of modern construction and industry. In future applications, this pump unit will continue to leverage its strong adaptability and engineering advantages to become a core component in fire water supply systems, providing strong support for urban safety and industrial development.