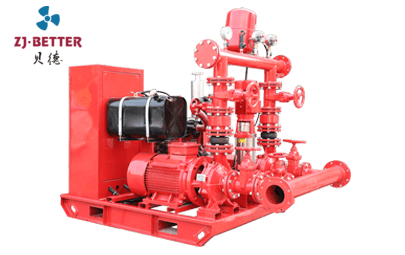

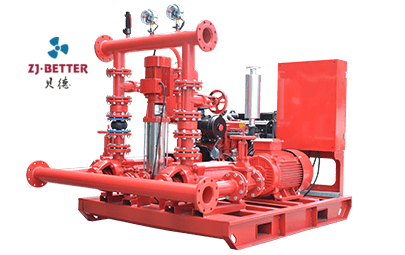

High-Precision Pressure Maintenance Pump Package: A Low-Energy, High-Reliability Constant Pressure Solution for Fire Protection Projects

High-precision pressure-stabilizing pump units provide precise pressure replenishment, intelligent control, and efficient operation, maintaining stable pressure for fire protection systems and improving overall reliability. They are an ideal choice for pressure stabilization solutions in various engineering projects.

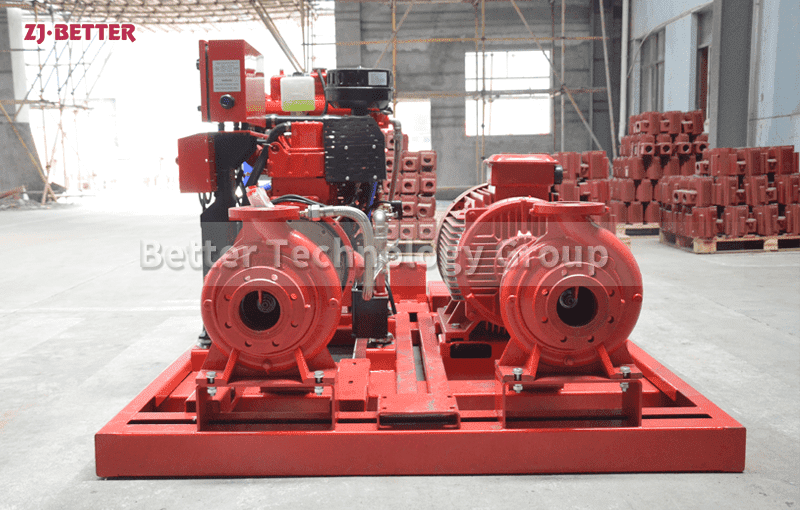

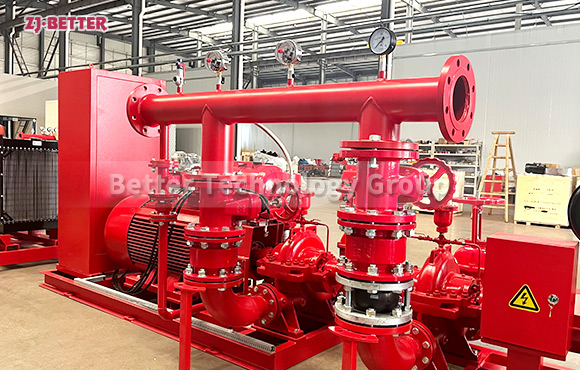

High-precision pressure-stabilizing pump units are a crucial type of equipment in modern fire protection systems. They play a vital role in ensuring constant pressure in the pipeline network, reducing frequent main pump starts, and improving the reliability of the fire protection system. They are widely used in various engineering projects both domestically and internationally. With the rapid development of high-rise buildings, industrial parks, large warehouses, and integrated commercial complexes, the performance requirements for pressure-stabilizing equipment in fire protection systems are constantly increasing. High-precision pressure-stabilizing pump units, with their advantages of low energy consumption, high efficiency, and high durability, have become the preferred pressure stabilization solution in many projects. These devices employ a high-efficiency pump structure, precise pressure control methods, and intelligent electrical control systems, enabling them to maintain excellent performance during long-term operation and under complex conditions. The design concept of high-precision pressure-stabilizing pump units is to provide a stable pre-pressurization state for the fire protection pipeline network, ensuring that the pipeline is always ready for immediate firefighting operations. Once the system pressure falls below the set value, the pressure-stabilizing pump will automatically start, rapidly replenishing the pressure within a short time, restoring the pipeline network to the normal pressure range. This ensures that sprinkler systems, fire hydrant systems, or foam extinguishing systems can instantly execute start commands when a fire occurs, without waiting for the main pump to start and replenish pressure. This process not only improves the response speed of the fire suppression system but also effectively avoids wear and tear caused by frequent starts of the main pump due to slight pressure relief, making the overall fire protection system more reliable and durable. High-precision pressure-stabilizing pump units typically use vertical multistage centrifugal pumps as the core pressure supply equipment. The multistage structure provides high head, stable flow, and high efficiency operation under low-flow pressure replenishment conditions. The pump body is made of corrosion-resistant metal, and the internal flow components are precision-machined, ensuring the pump remains stable during long-term operation and minimizing vibration and noise. The multistage impeller design not only enhances pressure output capacity but also reduces energy consumption, maintaining extremely low operating costs during long-term standby pressure replenishment. This advantage is particularly prominent for fire protection systems that require continuous 24-hour pressure maintenance. Another core component of the pressure-stabilizing pump unit is the intelligent electrical control system, which not only monitors inlet and outlet pressures but also automatically starts or stops the pressure-stabilizing pump according to set parameters. When the system pressure reaches the upper limit, the equipment automatically shuts down without manual intervention, thus avoiding unnecessary energy consumption and wear. When the system pressure falls below the set value, the pressure-stabilizing pump immediately starts and enters the pressure-compensating mode to ensure that the pipeline pressure remains within a safe and stable range. The electrical control system is also typically equipped with multiple protection functions, such as water shortage protection, overload protection, short circuit protection, and phase sequence protection, ensuring that the unit will not be damaged under various abnormal conditions. For large building complexes or locations with extremely high requirements for fire protection systems, the intelligent electrical control system can also support remote monitoring and automatic alarm functions, enabling maintenance personnel to understand the equipment’s operating status in real time and further improving system management efficiency. A stable air pressure compensation system is one of the important components of a high-precision pressure-stabilizing pump unit. Through the energy storage function of the pressure-stabilizing tank, the starting frequency of the pressure-stabilizing pump is effectively reduced. The pressure-stabilizing tank achieves buffering through the pressure balance of air and water. Pressure fluctuations caused by minor leaks or water hammer effects in the pipeline network are absorbed by the pressure-stabilizing tank itself and will not directly trigger the pressure-stabilizing pump to start. This design not only improves the stability of system operation but also significantly extends the service life of the pressure-stabilizing pump and greatly reduces operating costs. The pressure-stabilizing tank uses thickened steel and a corrosion-resistant coating process, allowing it to withstand high-pressure environments for extended periods, giving the system better durability. The performance advantages of high-precision pressure-stabilizing pump units are not only reflected in their reliability and durability, but also in their intelligence and efficiency. The equipment can be set with different pressure opening and closing values according to actual needs, meeting the requirements of fire protection projects of varying scales. Whether it’s a hotel, school, hospital, office building, or large industrial plant, optimal pressure stabilization can be achieved through parameter adjustments. Furthermore, the unit has a small footprint and compact structure, making it suitable for space-constrained machine room environments. Installation is convenient and maintenance is simple, making project implementation more flexible. The unit can be customized with different power pressure-stabilizing pumps, pressure-stabilizing tanks of various capacities, and multiple control methods according to project requirements, offering a high degree of customization. In terms of performance, it features rapid response, stable operation, low noise, and low energy consumption, making it one of the most competitive products in current fire protection pressure stabilization systems. Regarding safety, high-precision pressure-stabilizing pump units fully consider the stringent requirements of various fire protection systems, maintaining stable operation even in high-temperature, high-humidity, dusty, or vibrating environments. The pump body sealing structure is reinforced to ensure no leakage occurs during long-term operation. The electrical components within the control system are all industrial-grade components with high heat resistance and reliability, enabling rapid mode switching or automatic alarm activation in emergencies. Furthermore, the entire unit adopts a modular design, facilitating not only installation and transportation but also future replacement or upgrades. In terms of maintenance, the equipment structure is clear, and routine maintenance items such as pressure gauge checks, water tank pre-charge pressure testing, and motor lubrication are easy to implement, making the system more maintainable in long-term operation. Overall, the high-precision pressure-stabilizing pump unit, with its superior performance, intelligent control methods, and highly reliable design, has become a widely used pressure-stabilizing solution in the industry. In fire emergencies, it ensures that the fire protection system can be put into operation as quickly as possible, improving the success rate of fire extinguishing and providing a solid guarantee for the safety of buildings and personnel. As fire protection technology continues to advance, pressure-stabilizing pump units will continue to develop towards high efficiency and energy saving, intelligent operation and maintenance, and stable durability, continuing to provide reliable fire pressure guarantees for various projects.