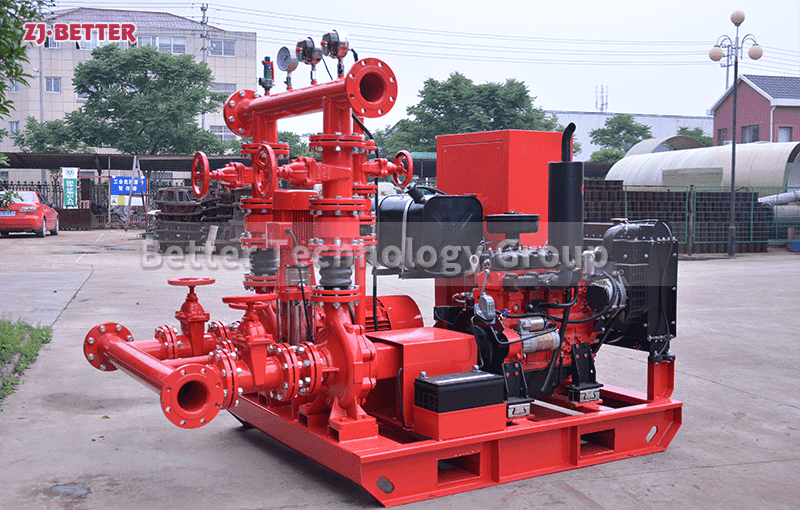

Automated Diesel Fire Pump System: Smart Fire Equipment for Faster Emergency Response

The automated diesel fire pump system features independent power supply, intelligent start-up, high-efficiency hydraulic output, and comprehensive operation monitoring capabilities. It can continuously provide stable fire water supply in the event of power outages and harsh environments. It is suitable for industrial parks, petrochemical bases, high-rise buildings, and various emergency fire protection projects, and is a highly reliable emergency equipment to ensure fire safety.

Automated diesel fire pump systems, as crucial core power equipment in modern fire protection engineering, are widely used in industrial plants, commercial complexes, petrochemical bases, municipal engineering projects, water conservancy facilities, and critical scenarios where mains power cannot be relied upon, thanks to their strong independent operation capability, intelligent control performance, and stable output even in complex environments. The most significant characteristic of these systems is their use of diesel engines as the primary power source. Through automated control programs, they achieve rapid start-up, stable operation, and real-time monitoring of the fire pumps, thus maintaining reliable fire-fighting water supply capabilities during sudden fires or power outages. The entire system typically consists of a diesel engine, fire pump, control cabinet, automation modules, pipe and valve assemblies, pressure stabilizing device, fuel system, cooling system, exhaust system, and an integrated base. Each module relies on precision design and engineering-grade manufacturing, laying the foundation for the equipment to output high-flow, high-lift, and highly reliable fire-fighting water supply capabilities. The core advantages of automated diesel fire pump systems are primarily reflected in their independent startup capability. The system has a built-in intelligent control module that monitors pipeline pressure in real time via a pressure signal acquisition device. When the pressure drops to a set value or a fire alarm command is received, the system automatically executes the startup process without manual intervention. From ignition, preheating, reaching rated speed, to stable water supply, everything is intelligently completed by the program, greatly improving the speed of initial fire response. Compared to traditional pump sets requiring manual operation, this system can achieve a second-level response in emergency situations, reducing the risk of fire spread due to startup delays. Secondly, the equipment uses a high-performance diesel engine as its power core, possessing strong output power and continuous working capacity. It can operate stably in scenarios where mains power is unavailable, such as power outages, severe weather, grid failures, or remote areas, ensuring a high-intensity water supply even in disaster situations. The diesel engine and fire pump use a high-standard coupling or direct-drive structure, resulting in higher power transmission efficiency, less energy loss, reduced vibration, and extended overall equipment lifespan. The pump body is typically made of high-strength cast iron, stainless steel, or corrosion-resistant alloys, ensuring stable hydraulic performance even during long-term operation. The intelligent performance of automated diesel fire pump systems is not only reflected in automatic start-up but also in comprehensive operational monitoring capabilities. For example, real-time monitoring of oil pressure, water temperature, speed, load, fuel level, battery status, exhaust temperature, and water supply pressure and flow can all be performed. The monitoring system processes abnormal signals through automated logic; for example, it automatically limits power, triggers alarms, or shuts down the system in cases of low oil pressure, high water temperature, or abnormal speed, ensuring that the diesel engine and pump operate within safe limits. Furthermore, many systems support integration with fire control centers, building automation systems, or cloud monitoring platforms, enabling remote monitoring and fault diagnosis, which helps improve the overall management efficiency of the fire protection system. The system adopts a highly modular layout in its structural design, mounting the diesel engine, fire pump, control cabinet, fuel tank, vibration damping devices, and silencer on a reinforced integrated base. This facilitates convenient transportation and simple installation, effectively reducing vibration transmission. The base is typically equipped with high-strength rubber vibration damping blocks, significantly improving operational stability and reducing the impact of vibration on the building structure. The cooling system uses an external circulating water-cooling or air-cooling design, enabling the equipment to maintain optimal efficiency during high-temperature or long-term operation. The exhaust system is equipped with an industrial-grade silencer, which significantly reduces operating noise, making it suitable for indoor machine rooms, underground spaces, and other locations with noise restrictions. The automated diesel fire pump system boasts high flow rate and high head combined hydraulic output capabilities. It can be customized to meet application requirements, accommodating flow rates from hundreds to thousands of cubic meters per hour and head requirements from tens to hundreds of meters. The pump unit’s efficiency has been comprehensively improved through optimized impeller, hydraulic structure, internal flow channel design, and precision machining, enabling the pump to maintain high efficiency under various operating conditions, reducing energy consumption and extending equipment life. The system can also be equipped with pressure-stabilizing pumps, pressure tanks, and pressure maintenance equipment to ensure stable pressure throughout the water supply system and prevent frequent pump start-ups and shutdowns. The equipment is also meticulously designed for safety and reliability. The fuel system features a large-capacity fuel tank to meet long-term continuous water supply needs and includes fuel level monitoring, fuel circuit protection, and leak-proof structures. The electrical system employs overload protection, short-circuit protection, phase sequence protection, and an intelligent charging module to ensure the starting battery remains in good condition at all times. The control cabinet features a standardized internal layout, fire-resistant and flame-retardant cables, and industry-standard certified switching components, ensuring it can withstand high-load operation in emergency situations. The system incorporates high-quality check valves, gate valves, pressure gauges, and safety valves in its piping system to guarantee safety and sealing stability even under high-speed water supply conditions. The automated diesel fire pump system has a wide range of applications, including industrial parks without mains power, petrochemical tank farms, storage bases, airports, docks, mining areas, oil pipeline stations, high-rise building complexes, cold storage facilities, logistics centers, water plants, and power plants. It is particularly suitable for projects requiring high reliability and emergency response capabilities. In practical applications, the system can serve as the main fire pump or be combined with an electric fire pump to form a dual-power fire water supply solution, ensuring continuous water supply under any circumstances through automatic switching. The system design adheres to international fire protection standards and supports customization according to the requirements of different countries and regions, making it suitable for global market needs. In conclusion, the automated diesel fire pump system, with its powerful performance, automated control, intelligent monitoring, high-efficiency hydraulic performance, stable and reliable structural design, and outstanding performance under extreme conditions, has become an irreplaceable and crucial piece of equipment in modern fire protection projects. Whether in the event of a sudden fire, power outage, or complex environment, it can ensure the continuity and stability of fire-fighting water supply in the most direct and reliable way, providing solid fire safety protection for various projects and facilities.