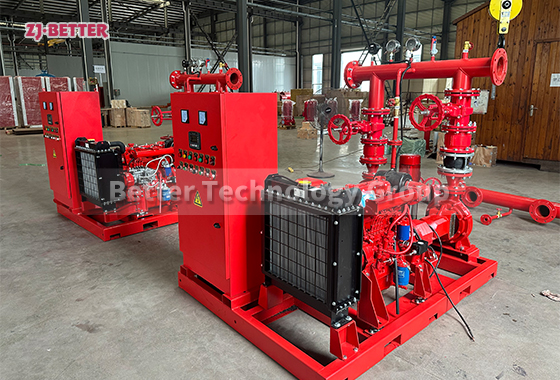

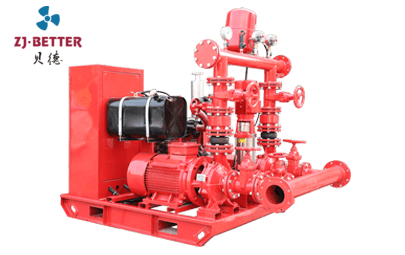

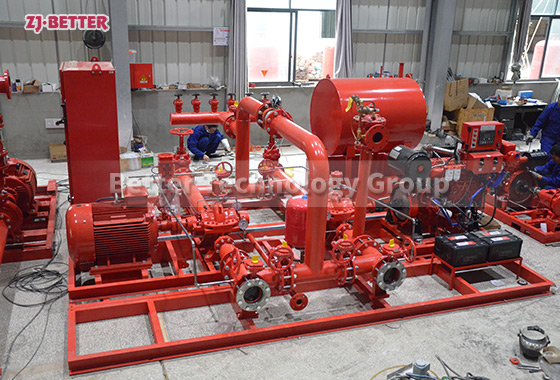

Diesel Fire Pump System for Hydrant and Sprinkler Water Supply

Diesel fire pump systems designed for hydrant and sprinkler applications, providing independent diesel power, high flow water supply, stable pressure, automatic startup, and reliable continuous operation for fixed fire protection systems.

The application of diesel fire pump systems in fire hydrant and automatic sprinkler systems is a crucial component of modern fixed fire protection engineering, ensuring core water supply capabilities. It plays an irreplaceable role, especially in locations with extremely high requirements for reliability, continuous operation, and independent emergency power supply. These diesel fire pump systems use a diesel engine as a power source, driving the dedicated fire pump body through mechanical transmission. During a fire, they provide a stable, efficient, and continuous supply of fire-fighting water to the fire hydrant and sprinkler systems. Even in extreme situations such as power outages or damage to the power system, they can maintain normal operation, buying valuable time for personnel evacuation and firefighting operations. Structurally, diesel fire pump systems typically employ a modular design, integrating the diesel engine, fire pump, cooling system, fuel system, exhaust system, control system, and inlet/outlet water pipes and valve assemblies onto a unified steel base. The components are rationally arranged and securely connected, ensuring system stability and facilitating on-site installation and subsequent maintenance. To address the different water usage characteristics of fire hydrants and sprinkler systems, diesel fire pump systems possess strong adaptability in flow and pressure configuration. They can output large instantaneous flow rates in a short time to meet the manual firefighting needs of fire hydrant systems, while maintaining stable pressure and continuous water supply for extended periods to meet the continuous operation requirements of automatic sprinkler systems, ensuring that the overall system performance remains unaffected when multiple points use water simultaneously. As the core actuator of the system, the hydraulic performance of the fire pump directly determines the water supply effect. High-efficiency fire-specific pumps are typically used, with pump bodies made of high-strength, pressure-resistant materials and meticulously designed internal flow channels. This ensures good hydraulic efficiency even under high head and high flow conditions, reducing energy loss and internal scouring, and extending equipment lifespan. The selection of diesel engines prioritizes low speed, high torque, and high reliability, ensuring smoother operation under firefighting conditions. Even under prolonged full-load operation, it maintains stable power output, minimizing power attenuation or overheating shutdown. The cooling system plays a crucial role in diesel fire pump systems. Through the rational configuration of high-efficiency radiator tanks, forced air cooling, or closed-loop water cooling structures, it effectively controls the diesel engine’s operating temperature, enabling the system to maintain optimal performance under high ambient temperatures or continuous operation, providing an uninterrupted water supply for fire hydrants and sprinkler systems. The fuel system design prioritizes the continuity and safety of fuel supply, equipped with reliable fuel delivery and filtration devices to ensure a stable fuel supply to the diesel engine during emergency starts and continuous operation, thus preventing disruptions to the fire pump’s normal operation due to insufficient fuel supply. The control system is a key component for achieving automation and safe operation of the diesel fire pump system. It typically features automatic start, manual control, operating parameter display, and multiple alarm functions. When the fire pipeline pressure drops or a fire alarm signal is received, the system can automatically start the diesel engine and drive the fire pump into operation within a very short time, without manual intervention, significantly improving emergency response efficiency. The control system can also monitor key parameters such as oil pressure, water temperature, speed, and battery voltage in real time. In case of abnormalities, it promptly issues audible and visual alarms to alert management personnel, extending operating time as much as possible while ensuring system safety. Considering the long-term standby status of fire hydrants and sprinkler systems, the diesel fire pump system is designed with startup reliability in mind. Optimized startup logic and battery configuration ensure successful startup even after prolonged periods of inactivity, preventing startup failures from hindering firefighting operations at critical moments. The modular design allows for complete assembly and performance testing of the diesel fire pump system before delivery, ensuring proper matching and coordinated operation between components. On-site installation only requires foundation fixing and piping and electrical connections, effectively shortening the construction period, reducing on-site commissioning difficulty, and mitigating operational risks caused by inconsistent installation quality. From an operational stability perspective, the diesel fire pump system exhibits good mechanical balance during startup, acceleration, and stable operation. Combined with a robust base structure and reasonable piping support, it effectively reduces vibration and noise, minimizing impact on the pump house structure and surrounding equipment, thus contributing to long-term reliable system operation. Ease of maintenance is also a significant advantage of diesel fire pump systems, widely recognized in fire hydrant and sprinkler systems. The overall layout is clear, key components are easily accessible, and daily inspections, periodic maintenance, and necessary parts replacements are relatively simple, helping to reduce operation and maintenance difficulty and long-term management costs. In summary, diesel fire pump systems, with their independent and reliable power source, excellent water supply performance, good continuous operation capability, and highly integrated design, demonstrate significant application advantages in fire hydrant and automatic sprinkler systems, making them key water supply equipment for ensuring the fire safety of large buildings, industrial facilities, and critical infrastructure. As fire safety regulations and engineering requirements continue to improve, the application value of this type of diesel fire pump system in fixed fire protection projects will be further highlighted, providing more stable, reliable, and efficient fire water supply for complex and diverse fire scenarios.