The Key Role of Diesel Engine Fire Pumps in Industrial and Commercial Buildings

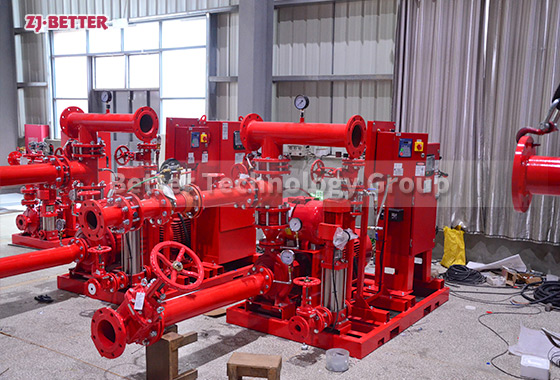

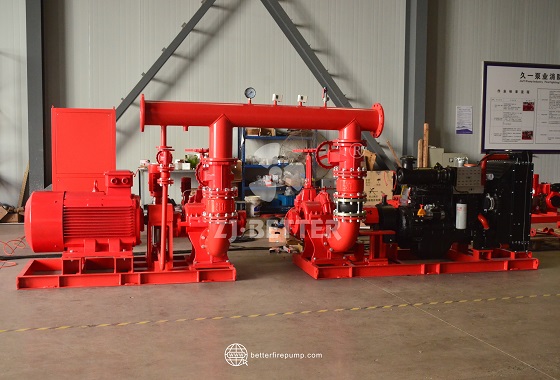

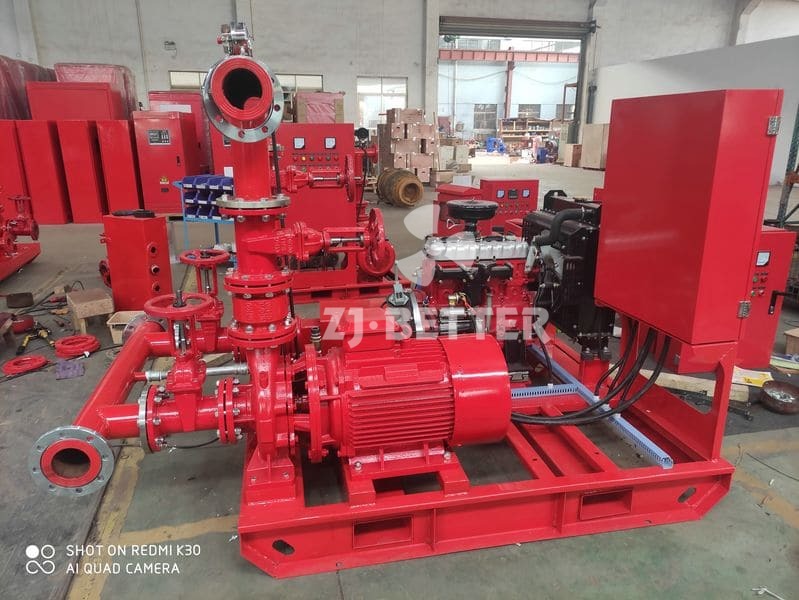

Diesel fire pumps provide independent and reliable fire water supply for industrial and commercial buildings. They feature efficient power, intelligent control, and strong adaptability to ensure uninterrupted emergency water supply in case of fire.

The key role of diesel fire pumps in industrial and commercial buildings With the continuous advancement of modern urbanization and the rapid development of large-scale industrial and commercial facilities, fire safety has gradually become an important link affecting public safety and economic operation. In the fire protection system, the fire pump, as the core water supply equipment, undertakes the key task of directly providing stable water flow and pressure to the fire extinguishing system. Among them, the diesel fire pump has become an indispensable important fire protection equipment for industrial and commercial buildings with its independent power drive, superior performance and reliable guarantee capability. The biggest feature of the diesel fire pump is the independence of its power source. Unlike the electric pump that relies on electricity, the diesel pump group does not rely on the external power system. It can still operate independently in the event of power outage, short circuit or insufficient power supply. This advantage makes it play an irreplaceable role in commercial complexes, high-rise office buildings, large shopping malls, factory workshops, petrochemicals, warehousing and logistics, and other fields with extremely high requirements for fire protection systems. This independent energy supply feature ensures that in the dual crisis of sudden fire and power system failure, the fire protection system can still be started in time to provide continuous and stable water for fire fighting, buying precious time for personnel evacuation and fire fighting. In terms of performance, diesel fire pumps have the advantages of high efficiency and strong power output. Modern pump groups generally adopt advanced fluid mechanics structure in their design to optimize the matching of impeller and pump body, so that they can operate at relatively low energy. It can achieve greater flow and higher head at low power consumption, and can meet the needs of high-rise buildings and large-scale factories for long-distance water transmission and high-pressure water supply. At the same time, the pump body is mostly made of high-strength cast iron or corrosion-resistant alloy, combined with wear-resistant mechanical seals, which effectively improves the service life and operation stability of the equipment, ensuring that the performance is not attenuated even during long-term high-intensity work. In terms of control systems, diesel engine fire pumps are usually equipped with advanced automatic control devices, which can realize one-button start, automatic switching and fault self-detection functions. When a fire occurs, it can respond quickly without human intervention, and some systems can also support remote monitoring and data collection, which is convenient for management personnel to grasp the operation status of the equipment in real time, and promptly discover and eliminate hidden dangers. This intelligent management method greatly improves the reliability and operational convenience of the fire protection system. The diesel fire pump also has excellent environmental adaptability. It can maintain normal operation in high temperature, low temperature, humid heat, dusty and even slightly corrosive gas environments. It is especially suitable for industrial scenes with strict requirements on operational stability, such as metallurgy, chemical industry, electric power and port facilities. Some models are also equipped with high-temperature resistant cooling systems and silencers, which not only ensure the stability of the equipment in harsh environments, but also reduce operating noise, improve the comfort and environmental protection of use. In industrial buildings, the role of diesel fire pumps is mainly reflected in ensuring production continuity and reducing fire losses. Due to the dense equipment and many combustible materials in factories, 2. High fire risk. Once a fire occurs, if you rely on electric pumps, the firefighting may fail due to power outages. Diesel pumps can operate independently to ensure that the fire water supply is not interrupted, thereby minimizing the damage to production and property caused by fire. In commercial buildings, its role is more prominent in personnel safety. Large shopping malls, hotels and office buildings are crowded. Once a fire occurs, a fast and effective fire extinguishing system is crucial for personnel evacuation. Diesel fire pumps can start quickly in an emergency to ensure continuous water supply to the sprinkler system and fire hydrant system, avoiding delays in firefighting due to power outages, thereby protecting the lives of hundreds or even thousands of people. In addition, diesel fire pumps are designed with great emphasis on maintenance. The overall structure is reasonable and has sufficient maintenance space for operators to conduct daily inspections and replace parts. At the same time, the core components have a long life, a long maintenance cycle, and a relatively low operating cost, which makes it extremely cost-effective throughout its life cycle. In the long run, it can effectively reduce the total cost of fire protection investment for enterprises and building operators. In actual applications, diesel fire pumps usually form a dual power system with electric fire pumps, which serve as backup for each other. When the electric pump fails to operate, the diesel pump automatically takes over to ensure uninterrupted water supply. This double insurance mode is widely used in international fire protection specifications and is also an important configuration solution for high-level fire protection systems. It not only improves the overall reliability of the system, but also The diesel fire pump has the advantages of being customizable. Users can choose pump sets with different flow rates, lifts and powers according to the building scale, water demand and fire regulations. Users can also configure automatic heating systems to ensure rapid start-up in low-temperature environments, or select noise reduction and emission optimization devices to meet environmental protection requirements. This highly flexible customization capability enables it to be widely adapted to various scenarios, from petrochemical plants to shopping centers, from power stations to high-rise residential areas, and can provide professional fire water supply solutions. Overall, diesel fire pumps are widely used in industrial and commercial buildings. The key role of is not only to provide a reliable source of water for fire extinguishing, but also to provide the safety guarantee and core support for the entire fire protection system. With its advantages of independent drive, strong performance, intelligent control, wide adaptability and convenient maintenance, it fully meets the high standards of modern buildings for fire protection systems, and provides a solid foundation for improving building safety levels and reducing fire risks. In the future, with the further development of intelligent and environmentally friendly energy-saving technologies, diesel fire pumps will continue to innovate in product design and application, improve energy efficiency, reduce emission levels, and strengthen remote monitoring functions, so as to better serve the fire protection needs of industrial and commercial buildings around the world and become one of the indispensable important equipment in the modern urban fire protection system.