Multi-Parameter Monitored Fire Pump Units Supporting Intelligent Fire Water Management

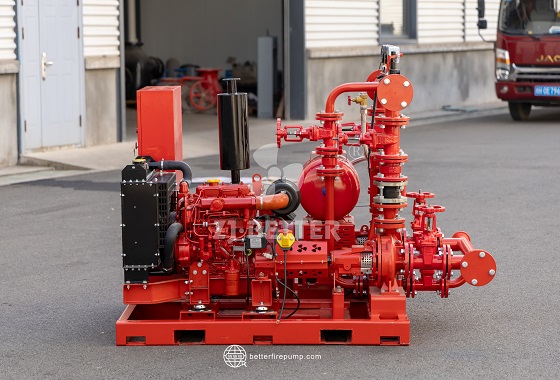

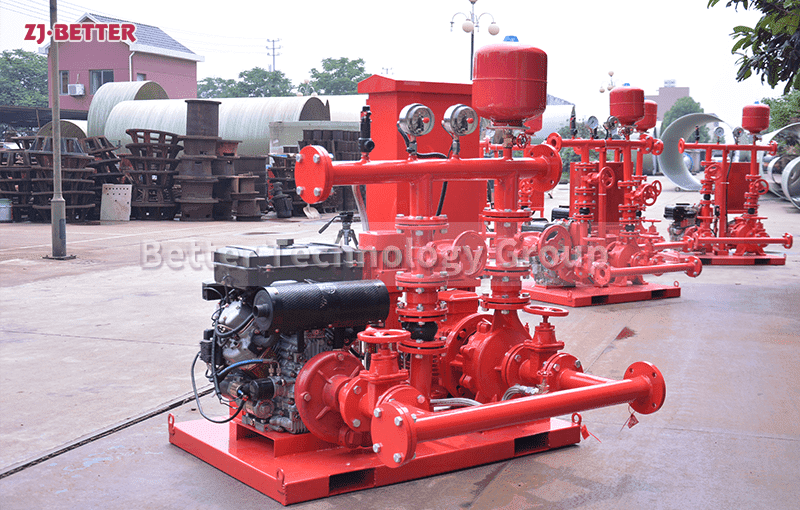

Multi-parameter monitoring fire pump units integrate real-time pressure, flow, and operating status monitoring functions, and have the advantages of rapid start-up, stable water supply, and intelligent protection. They are suitable for building and industrial fire protection systems, effectively improving the safety, reliability, and management efficiency of fire water supply.

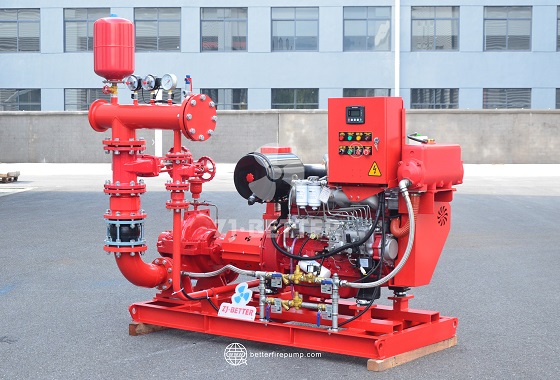

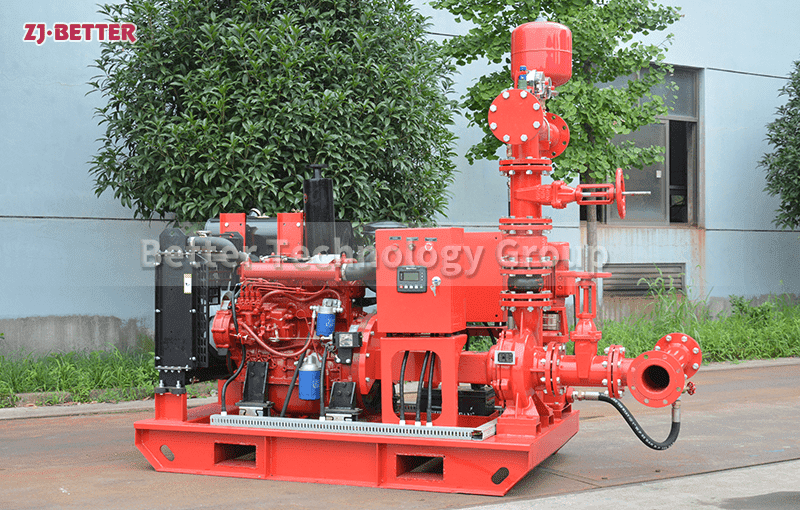

This multi-parameter monitoring fire pump unit is a highly integrated water supply device designed to meet the needs of modern building and industrial fire protection systems. Its overall structure is based on the core concepts of stability, efficiency, and intelligence. Through real-time monitoring and coordinated control of key parameters such as flow rate, pressure, temperature, voltage, current, and operating status, it achieves accurate response and reliable operation of the fire water supply system under various working conditions. The product adopts a mature fire pump hydraulic model design, and the pump body flow channel has been optimized, resulting in minimal internal hydraulic losses. It maintains a good efficiency curve under both rated and unbalanced operating conditions, effectively ensuring rapid system pressure establishment upon startup, meeting the stringent “ready-to-use” requirements of fire protection systems. The drive section uses a high-reliability motor or engine as the power core, ensuring stable output and reasonable matching. Power is efficiently transmitted to the pump shaft through a flexible coupling or direct-drive structure, reducing mechanical energy loss and vibration sources, fundamentally improving the overall operational stability and service life of the unit. A major advantage of this fire pump unit lies in its multi-parameter monitoring capability. The control system integrates various high-precision sensors to continuously collect data on inlet and outlet pressures, pipeline pressure changes, motor operating current, winding temperature, bearing condition, and system power status. This data is displayed intuitively on the control panel, allowing operators to quickly grasp the equipment’s operating status without requiring specialized commissioning experience. This significantly reduces the risk of manual judgment during fire duty or routine inspections. The control logic design follows the actual operational needs of the fire protection system, supporting multiple modes including automatic start-up, automatic shutdown, fault alarm, anomaly protection, and manual emergency operation. In the event of a fire or a sudden drop in pipeline pressure, the system can start up and maintain stable water supply pressure in a very short time, preventing water supply interruptions due to delays or misoperation. Considering the characteristics of fire protection equipment that is typically idle for extended periods, the unit’s design prioritizes reliability and low maintenance. Key components are made of wear-resistant and corrosion-resistant materials, and the sealing system employs mature mechanical seals or packing seals to ensure good sealing performance even under long-term static or periodic start-up conditions, reducing the probability of leakage and malfunctions. In terms of structural layout, the unit adopts an integrated base design, with the pump body, power unit, control cabinet, and cooling system rationally arranged. This ensures overall stability and a compact footprint, facilitating both factory assembly and commissioning, as well as rapid on-site installation and subsequent maintenance. The control cabinet boasts excellent protective performance, adaptable to use in machine rooms, underground pump rooms, or semi-open industrial environments, effectively preventing dust and moisture from affecting electrical components. The multi-parameter monitoring system ensures safety while providing crucial data support for the daily management of the fire protection system. Analysis of operating records and historical parameters allows for early detection of potential hazards, enabling preventative maintenance and reducing the risks and costs associated with sudden failures. This fire pump unit exhibits outstanding pressure stabilization performance, automatically adjusting its operating status under fluctuating water supply or multi-point water intake conditions to maintain system pressure within a reasonable range. This avoids frequent start-stop cycles that could impact equipment, thus extending the overall system lifespan. The product’s design fully considers the needs of various application scenarios, making it suitable for high-rise buildings, commercial complexes, hospitals, data centers, and other locations with extremely high requirements for continuous water supply, as well as industrial parks, warehousing and logistics facilities, and production workshops requiring reliable fire protection. Before leaving the factory, the entire unit undergoes rigorous performance testing and operational verification to ensure that the flow rate, head, power, and monitoring functions all meet design requirements. In actual use, it demonstrates comprehensive advantages such as reliable start-up, stable operation, and rapid response. By combining the mechanical reliability of traditional fire pumps with modern intelligent monitoring technology, this multi-parameter monitoring fire pump unit not only improves the safety level of the fire water supply system but also significantly enhances the visualization and controllability of system management. It is an ideal choice for current fire protection engineering projects that balance performance, efficiency, and intelligence.