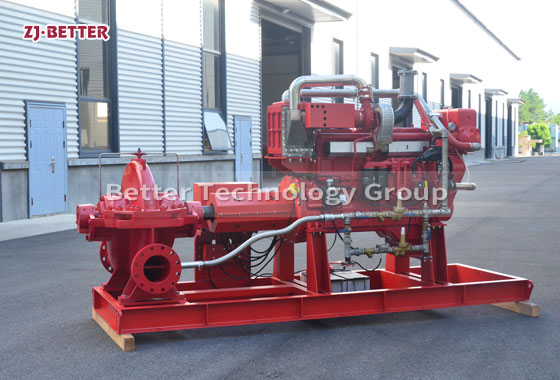

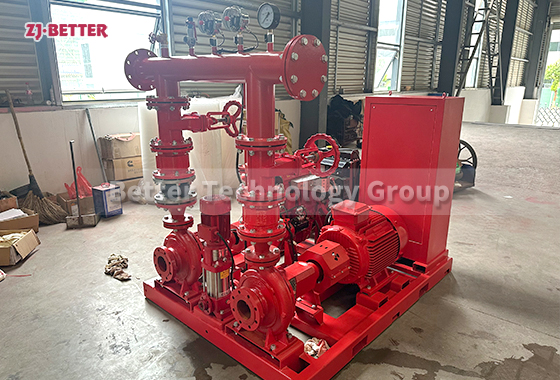

The Core Force of Industrial and Building Fire Protection: Powerful Output of High-Head Diesel Fire Pumps

High-lift diesel fire pumps are renowned for their powerful power, independent operation, and high-pressure water supply, making them an ideal choice for fire protection systems in industrial plants, high-rise buildings, and petrochemical bases. They offer advantages such as automatic control, energy conservation and environmental protection, and high-temperature and corrosion resistance, ensuring stable operation during power outages and extreme environments, providing continuous and efficient fire water support.

High-lift diesel fire pumps, an indispensable component of modern firefighting systems, are core equipment for ensuring fire safety in various projects, thanks to their independent drive, powerful power, high-efficiency output, and superior adaptability. Whether in high-rise buildings, industrial plants, warehouses and logistics centers, petrochemical bases, or infrastructure construction in remote areas, these fire pumps provide a continuous and stable high-pressure water supply at critical moments, ensuring rapid activation of firefighting systems and maintaining effective firefighting pressure. Their design integrates advanced technologies such as mechanical dynamics, hydraulic transmission, and automatic control, ensuring safe, reliable, and efficient firefighting water supply in all conditions. The diesel engine drive system is the core power source of these fire pumps. Compared to electric fire pumps, the diesel engine’s greatest advantage lies in its independent operation. If a fire disrupts the power system, the diesel fire pump can immediately start, ensuring uninterrupted water supply to the firefighting network and avoiding delays in firefighting operations. The high-performance diesel engine is meticulously tuned for fast startup, low fuel consumption, and high torque output, reaching rated speed and driving the fire pump into operation within seconds. It can maintain stable operation in extreme environments. Its high-temperature, vibration-resistant, and corrosion-resistant structural design ensures long-term, efficient water supply even under high-intensity conditions. High head is a key performance characteristic of this type of fire pump. By optimizing the impeller curve, improving the pump flow efficiency, and utilizing wear-resistant, high-strength materials, this device delivers stable flow and head even under high-pressure conditions, ensuring rapid delivery of firefighting water to the tops of high-rise buildings or remote injection points. Whether in a hundred-meter-high building or a large factory area, this high-head diesel fire pump provides sufficient pressure support, providing a stable water supply for sprinkler systems, fire hydrant systems, and foam fire extinguishing systems. Its fluid dynamics design, validated by CFD simulation, ensures smooth flow within the pump, high efficiency, and low energy consumption, significantly improving overall operational economy. The control system features a fully automatic intelligent control panel, enabling automatic start-up, automatic switching, and automatic alarm functions. Upon receiving a fire signal or a pressure drop command, the system automatically starts the diesel engine and activates the fire pump, requiring no human intervention. The control panel integrates multiple safety mechanisms, including monitoring of oil pressure, water temperature, speed, and the cooling system. Any abnormalities automatically shut down the unit and generate an alarm, effectively preventing equipment damage and operational risks. The intelligent monitoring module also supports connection to a fire monitoring center or remote management system, enabling remote monitoring, operating data logging, and maintenance alerts, significantly enhancing the equipment’s intelligence and reliability. The unit features a modular, integrated base structure for easy installation, compact layout, and simplified maintenance. The pump body and diesel engine are connected via a high-precision coupling, ensuring smooth operation with minimal vibration and noise. The base is welded from high-strength steel, offering excellent seismic resistance and suitable for industrial and outdoor installation. All key components are treated with corrosion protection to ensure stable operation even under long-term exposure to humidity, high temperatures, or chemical corrosion. The cooling system utilizes a dual-tank and air-cooled structure, ensuring the diesel engine maintains optimal temperature during prolonged, high-load operation, effectively extending its service life. The rationally designed lubrication and fuel systems ensure smooth startup and continuous operation in a variety of climate conditions. This high-lift diesel fire pump not only offers robust performance but also optimizes energy efficiency and environmental protection. High-pressure common rail fuel injection technology ensures more complete combustion, reduces emissions and fuel consumption, and complies with international environmental standards. The exhaust system features silencers and purification treatments, minimizing noise pollution while maintaining power output. This makes it ideal for installation in urban buildings or locations with stringent noise control requirements. The user-friendly design of the equipment makes daily inspections, fuel replenishment, lubricant changes, and filter cleaning quick and easy, significantly reducing operating and maintenance costs. High-lift diesel fire pumps are widely used in applications requiring high water pressure and reliability, such as fire water supply systems in high-rise buildings, automatic sprinkler systems in large warehouses and logistics centers, foam fire extinguishing systems in petrochemical plants, fire emergency systems at airports and docks, and emergency drainage systems in municipal engineering projects and underground facilities. Their superior performance enables them to operate reliably in a wide range of fire protection projects, providing strong technical support for fire safety. Compared to other types of fire pumps, diesel fire pumps offer greater independence and adaptability. They do not rely on an external power source and can operate independently under extreme conditions, making them an optimal solution for emergency fire water supply systems. Furthermore, it can be flexibly configured to meet specific needs, such as with a dual-pump system, a primary/standby pump switching system, and a linkage control system, ensuring optimal operation under various operating conditions. The device can also be used in conjunction with electric pumps and pressure-stabilizing pumps to form a comprehensive fire water supply system, further enhancing overall system safety and reliability. In terms of manufacturing, the device utilizes high-precision machining and rigorous quality inspection processes to ensure that every component meets international standards. The pump body undergoes high-temperature heat treatment and wear-resistant coating treatment to enhance corrosion resistance and durability. The diesel engine undergoes multiple load tests and dynamic balancing tests to ensure continuous, flawless operation at rated power. The entire unit undergoes rigorous performance testing before shipment, including key indicators such as start-up time, head, flow rate, vibration, and noise, to ensure stable and reliable product performance. Technological innovation is also a key area of continuous improvement for high-head diesel fire pumps. With the advancement of industrial automation and intelligent manufacturing, modern diesel fire pumps are increasingly adopting digital management and remote operation and maintenance. Leveraging IoT technology, real-time monitoring of equipment operating status, energy consumption, and maintenance cycles is enabled, providing users with a superior equipment management experience. This intelligent trend not only improves equipment efficiency but also makes firefighting systems safer, more reliable, and easier to maintain. High-lift diesel fire pumps, with their independent drive, high-pressure output, stable operation, and intelligent control, have become the core of modern firefighting systems. They not only provide a continuous and stable firefighting water supply at critical moments, but also offer users enhanced safety and economic benefits through efficient energy conservation and intelligent monitoring. Whether in industrial production, infrastructure, or high-rise buildings, this equipment silently safeguards every corner requiring safety protection, providing solid technical support and driving force for building a more reliable firefighting system.