Diesel fire pump can be used with other fire pumps

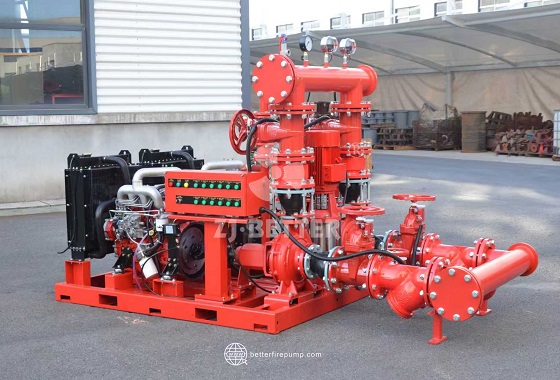

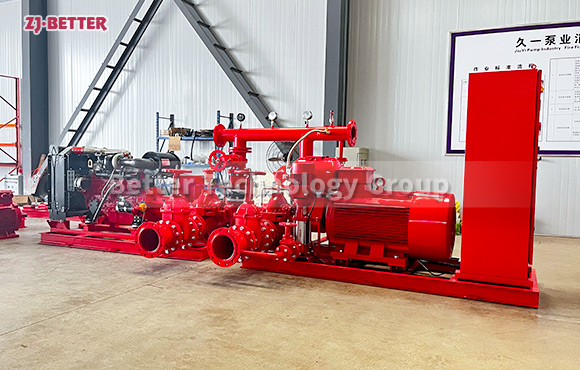

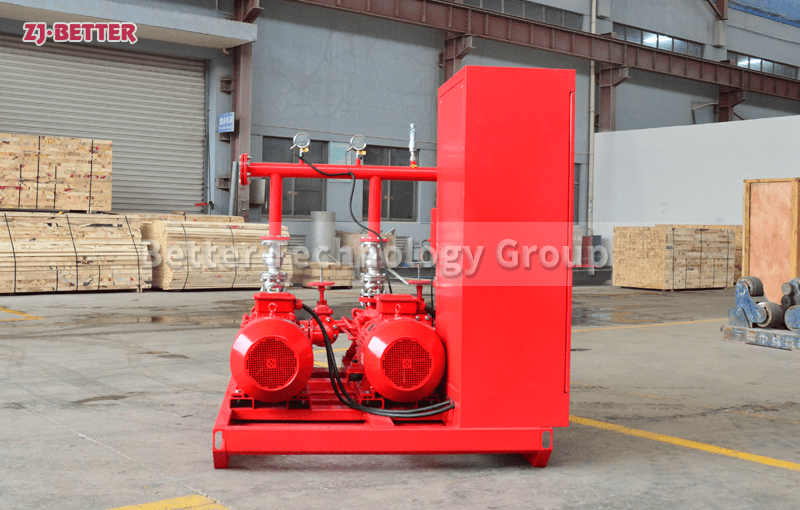

The diesel engine (can be equipped with a clutch) is combined with the fire pump through a highly elastic coupling to form a fire pump unit. The unit also includes diesel tanks, cooling water tanks, fans, control panels (for automatic units) and other components.

When the unit is automatically controlled, the split or diesel engine automatic control cabinet (programmable) realizes the automatic start, input, and automatic switching of the system (switching from the electric pump group to the diesel engine pump group or from this group of diesel engine pump groups to another group of diesel engines) pump set), automatic protection (diesel engine overspeed, low oil pressure, high water temperature, three start failures, low oil level, low battery voltage and other alarm shutdown protection) and other functions, and can also interface with the user’s fire center or automatic fire alarm device, Realize remote monitoring.

1. The housing of the diesel engine is made of high-strength ductile iron, the impeller and sealing ring are made of corrosion-resistant materials, and the shaft is made of SS420 stainless steel.

2. The operating efficiency of all diesel engine fire pump sets has reached the advanced level in the same industry.

3. The selected diesel engine has the advantages of small size, light weight, low fuel consumption, low emission, low noise and good starting performance.

4. Fully consider the structural strength and anti-corrosion performance of the diesel engine fire pump group to ensure the reliability of the pump. Once started, it can be put into operation at full capacity.

5. Diesel engine fire pumps are flexible in form. It can be used alone, and can be used in conjunction with fire pumps and voltage stabilizing equipment pumps for fire sprinkler systems.