Electric fire pumps are used in a wide range of occasions

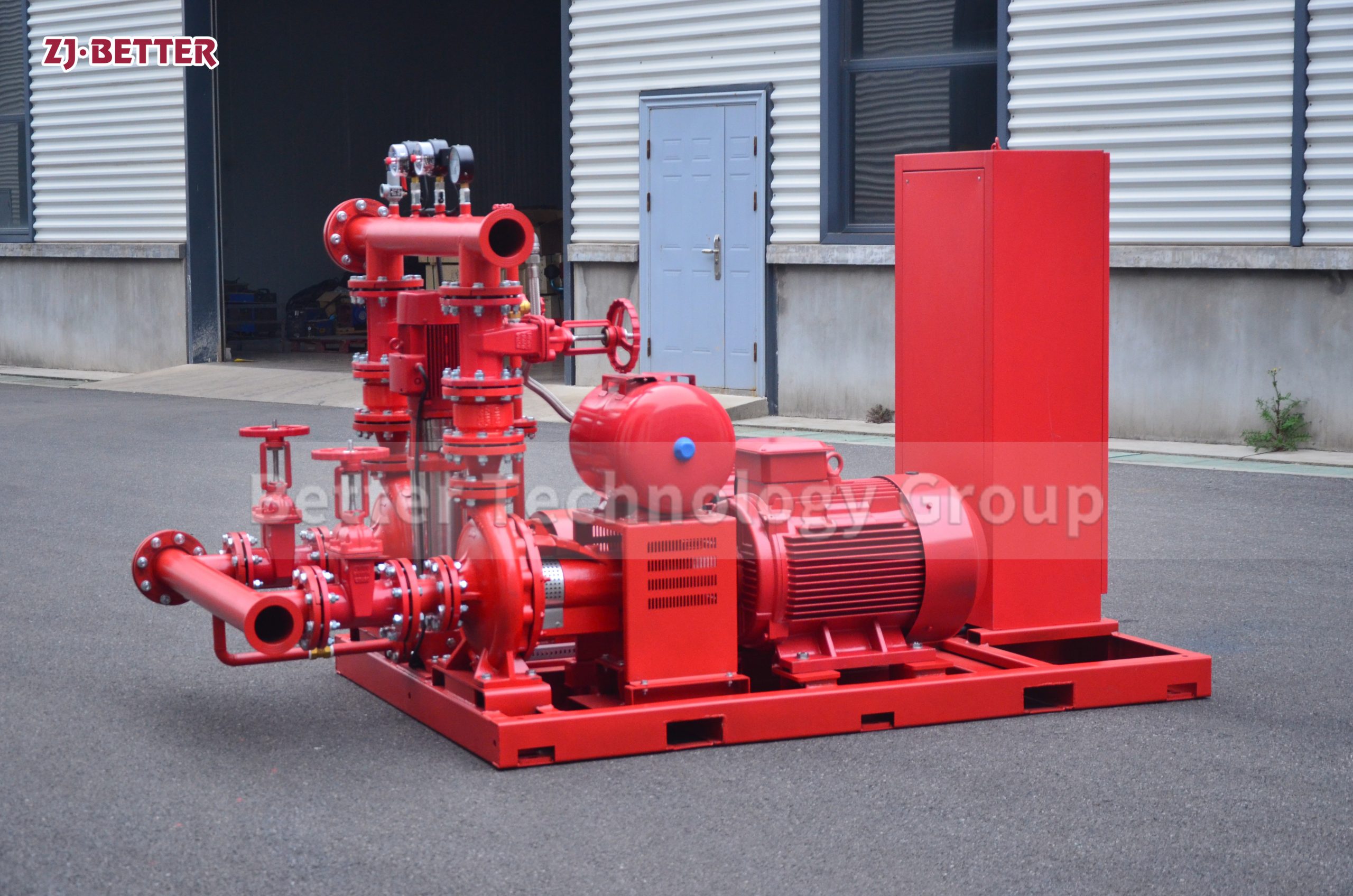

The electric fire pump set is a medium and low pressure fire pump product developed by our company in strict accordance with the technical requirements of the national standard GB6245-2006 (fire pump) and the National Fire Protection Association NFPA20 (installation of centrifugal fire pumps). The product has passed the type inspection of the National Fixed Fire Extinguishing System and Refractory Component Quality Inspection Center.

The electric fire pump set is suitable for fire protection engineering of steel, metallurgy, electric power, petroleum, chemical industry, construction, port and other operations, emergency water supply for blast furnace, continuous casting, converter and other accidents, power plant emergency water supply for power failure, nuclear reactor safety protection cooling water supply, and others Water supply projects requiring automatic control.

It mainly transports water without solid particles or liquid with viscosity similar to water. If the medium transported by the user contains acid or alkali, it should be negotiated with the company when ordering. The temperature of the transported medium is 0°C~+80°C. If appropriate cooling measures are adopted, the medium with a higher temperature can be transported.