Global Firefighting Upgraded: High-Efficiency Diesel Pump Sets for Better Performance and Energy Saving

Explore high-efficiency diesel fire pump sets designed for extreme environments, helping to upgrade global fire protection systems, combining reliable performance, energy-saving advantages and NFPA standard certification to meet the needs of various rigorous application scenarios.

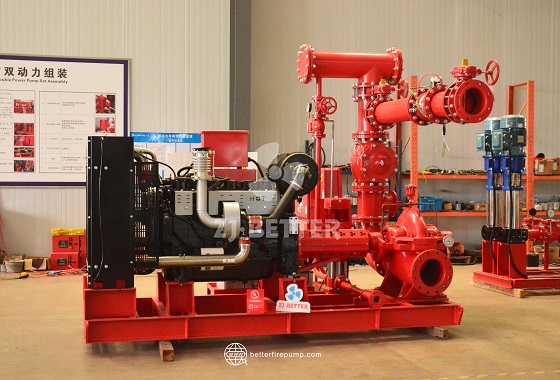

In modern building safety systems, fire pump equipment is one of the core power sources. Its stability, response speed and energy efficiency are directly related to the success or failure of the fire emergency system. In order to adapt to the growing global demand for high reliability and green energy saving, we have launched a new generation of high-efficiency diesel fire pump sets, which are specially designed for large buildings, industrial parks, ports, storage and logistics centers and high-risk industrial and mining environments. The pump set combines strong power performance with excellent energy consumption control technology to comprehensively improve the system response efficiency and provide continuous and stable fire water source guarantee under various extreme working conditions. The equipment has a compact structure, flexible installation method, and a highly modular design. It supports rapid deployment and intelligent control system integration. It is a truly high-efficiency, low-maintenance and highly adaptable product.

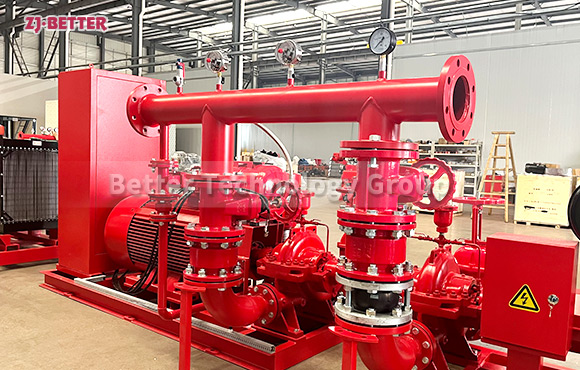

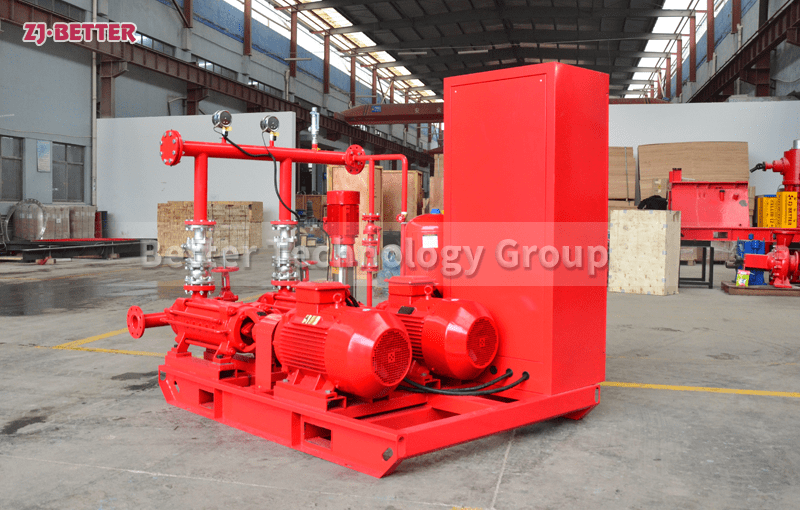

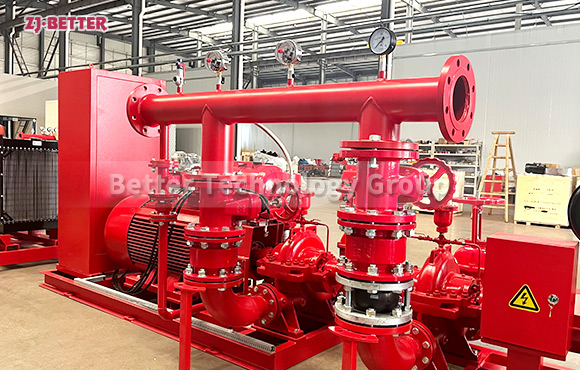

This series of diesel pump sets is centered on an excellent power system, and its engine part has multiple advantages such as fast start-up, efficient combustion, and stable output. The matching multi-stage fire pump or single-stage centrifugal pump is composed of high-precision castings, and the impeller and shaft seal structure are optimized and upgraded, which significantly reduces mechanical losses while increasing the head and flow. The entire power system is connected through an elastic coupling or an integrated base to minimize vibration and noise during energy transmission, ensuring that the entire pump group runs smoothly and quietly.

In order to further improve energy utilization, the diesel fire pump group is equipped with an intelligent fuel control system and an automatic cooling system, which not only reduces fuel consumption, but also extends the continuous operation time of the equipment. The independently developed control cabinet system adopts a modular PLC controller, with functions such as automatic/manual start-stop switching, voltage monitoring, fault alarm, remote control and fire linkage interface, which can achieve seamless connection with the building fire center and intelligent management system. In addition, the system also has an emergency self-check function to ensure that it is in a state of readiness at any time.

The pump group adopts an integral frame base design, which is sandblasted and sprayed with epoxy anti-corrosion paint, and has extremely high corrosion resistance. The pump body, joints, and pipes are made of stainless steel or wear-resistant cast iron to ensure long-term use without rust and leakage. The power distribution system is equipped with a voltage stabilizer and a battery automatic charger, which not only ensures the stable operation of the electronic control system, but also improves the independent combat capability of the pump group in power outage scenarios. For environments that require explosion-proof, explosion-proof control systems and electrical components can be optionally equipped to meet the requirements of special scenarios.

In addition, the diesel pump set also supports diversified customization services. Customers can choose a single pump, dual pump or one-to-three linkage pump set structure according to the actual needs of the project, providing constant pressure start, frequency conversion control, water-cooled/air-cooled engine selection, automatic refueling system, integrated remote monitoring module and other functions. We can also provide multi-language operation interface and remote maintenance assistance for overseas project needs, to achieve truly global universal, efficient response and localized adaptation.

From product design, raw material selection, manufacturing process to factory testing, we always adhere to international standards such as NFPA 20, ISO, CE, etc., to ensure that each diesel fire pump set has excellent reliability and engineering consistency. Each set of equipment undergoes strict full-load operation tests before leaving the factory, covering multiple dimensions such as start-up response, flow head, temperature rise control, electrical performance and alarm protection functions, to ensure that the equipment received by customers is plug-and-play and reliable.

With many years of industry experience and thousands of field project applications, we are well aware of the diverse requirements of fire pump systems in different countries, regions, and climate conditions. Therefore, before the equipment is delivered, we can provide environmental adaptability configurations including high temperature resistance, severe cold resistance, dust resistance, and flood resistance according to the usage scenario to ensure efficient and stable operation under extreme conditions. For island projects or oil and gas projects, seawater corrosion-resistant structures and explosion-proof grade certification can also be customized to truly tailor to customer needs.

This high-efficiency diesel fire pump set is not only the crystallization of technology and quality, but also reflects our continued pursuit of safety, energy saving and intelligent management. It is not only a powerful guarantee for dealing with various emergency fire scenarios, but also an important driving force for promoting the global fire protection system to move towards automation, greening, and internationalization. In the future, we will continue to increase our investment in diesel pump technology and intelligent control systems, and empower the development of the global fire protection industry with more innovative products.