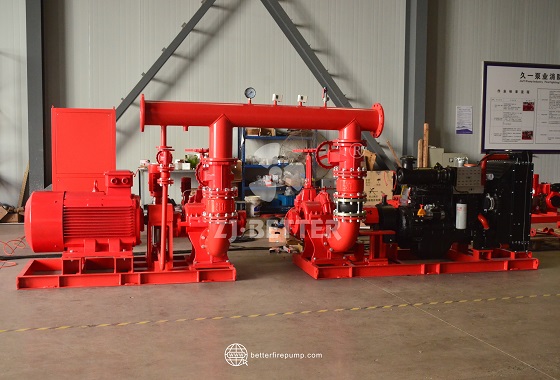

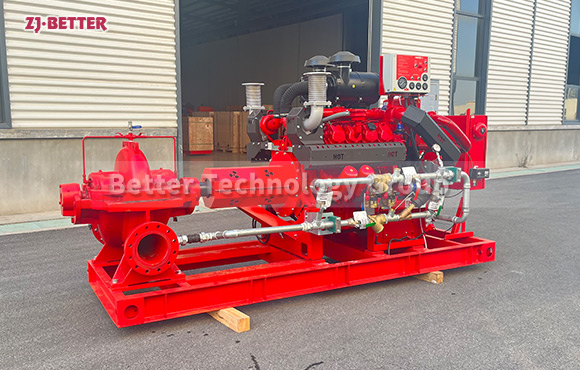

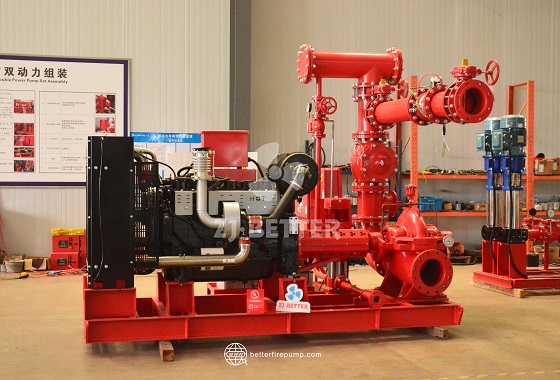

High Head Diesel Fire Pump Package for High-Rise and Large Building Fire Protection

The high-head diesel fire pump system is specifically designed for high-rise buildings and large industrial fire protection. It features stable high-pressure water supply, independent diesel power, automatic start-up, and multiple safety protections, making it suitable for municipal, commercial, and critical infrastructure fire protection systems.

The high-head diesel fire pump system is specifically designed for applications requiring extremely high fire water supply pressure and reliability, such as high-rise buildings, large industrial plants, commercial complexes, data centers, warehousing and logistics parks, and municipal fire protection projects. This system utilizes a diesel engine as an independent power source, ensuring stable operation even during power outages or extreme conditions, making it a core component in maintaining the continuity of the fire safety system. The complete system typically consists of a high-head fire pump, diesel drive unit, flexible coupling, cooling system, fuel system, intelligent control cabinet, pressure stabilization and protection components, and a reinforced base. The overall structure is compact and well-designed, balancing high-performance output with long-term stable operation. The fire pump body is made of high-strength cast iron or ductile iron, and the internal flow channels are optimized using precision hydraulic models. This ensures high-head output while effectively reducing hydraulic losses, allowing the equipment to maintain a good efficiency curve even under high-pressure, high-flow conditions, preventing increased energy consumption and excessive wear due to long-term heavy-duty operation. The pump shaft and key rotating parts are made of high-quality alloy steel, precision machined and dynamically balanced, significantly improving the overall stability of the machine, reducing vibration and noise levels, and thus extending the service life of bearings and seals. High-head performance is one of the core advantages of this type of fire pump system. Through multi-stage impeller structures or optimized high-pressure single-stage designs, it can achieve stable water supply over long distances and high elevations within a limited installation space, making it particularly suitable for high-rise building fire riser systems, rooftop fire water tank replenishment, and pressure compensation for remote fire hydrants and sprinkler systems. In the event of a fire, the system can quickly establish sufficient pipeline pressure, ensuring that the most unfavorable fire fighting facilities still have sufficient water volume and spray intensity, gaining valuable time for firefighting operations. The diesel engine, as the power core, features reliable starting, stable torque output, and strong environmental adaptability. It does not rely on external power supply, ensuring that the fire pump can start and operate continuously even in the event of widespread power outages or damage to the power system. The diesel engine cooling system typically employs water cooling or a high-efficiency radiator structure, combined with a rational air intake and exhaust design, to effectively control temperature rise during high-load operation. This prevents power degradation or protective shutdown due to overheating, thus ensuring the continuity and stability of power output during prolonged firefighting operations. The fuel system design fully considers the specific requirements of firefighting applications, featuring a simple and reliable fuel line layout and comprehensive filtration and protection devices. This reduces the impact of impurities on the engine and lowers maintenance frequency, ensuring excellent starting performance even after extended periods of standby. The control system is a crucial component for achieving intelligent and safe operation of the high-head diesel fire pump system. By integrating automatic start, manual control, operation monitoring, and multiple protection functions, the system can respond quickly in emergency situations. The system can automatically start upon receiving a fire signal or detecting abnormal pipeline pressure, eliminating the need for manual intervention and significantly improving emergency response efficiency. Real-time monitoring of key parameters such as speed, oil pressure, water temperature, and operating time ensures that the equipment always operates within safe limits. In case of any abnormality, an alarm is triggered, providing valuable information for on-site management and subsequent maintenance. The system’s structural design emphasizes overall stability and ease of installation. A high-strength steel base provides overall support, effectively absorbing vibrations generated during operation and reducing their impact on building structures and pipeline systems. This also facilitates the overall lifting and positioning of the equipment within the equipment room. The pipe interfaces comply with common fire protection standards, allowing for quick connection to existing fire protection pipeline systems, shortening construction time, and reducing engineering costs. To meet the complex operating conditions of high-rise and large buildings, the system has been comprehensively reinforced for durability. Key sealing components use high-temperature and wear-resistant materials, maintaining excellent sealing performance under frequent starts and stops and prolonged high-pressure conditions, reducing the risk of leaks and ensuring overall system reliability. Furthermore, the system offers significant advantages in terms of daily maintenance. The functional modules are clearly laid out, and reasonable maintenance access is provided, facilitating inspection, maintenance, and component replacement by technicians, effectively reducing future maintenance difficulties and costs. From a safety perspective, the high-head diesel fire pump system is designed from the outset with full consideration of fire safety regulations and actual usage requirements. Redundant design and multiple protection mechanisms minimize the impact of single component failures on the overall system, ensuring continuous water supply at critical moments. Whether in high-rise building fires, accidents in high-risk industrial facilities, or critical engineering projects requiring continuous fire water supply, this system, with its stable high-pressure output capability, reliable diesel power support, and comprehensive control and protection system, provides robust technical support for fire fighting systems, making it an indispensable component of modern fire protection engineering.