Strictly follow the requirements to carry out the fire pump test

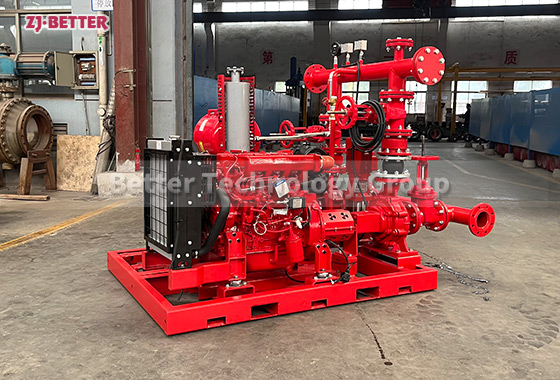

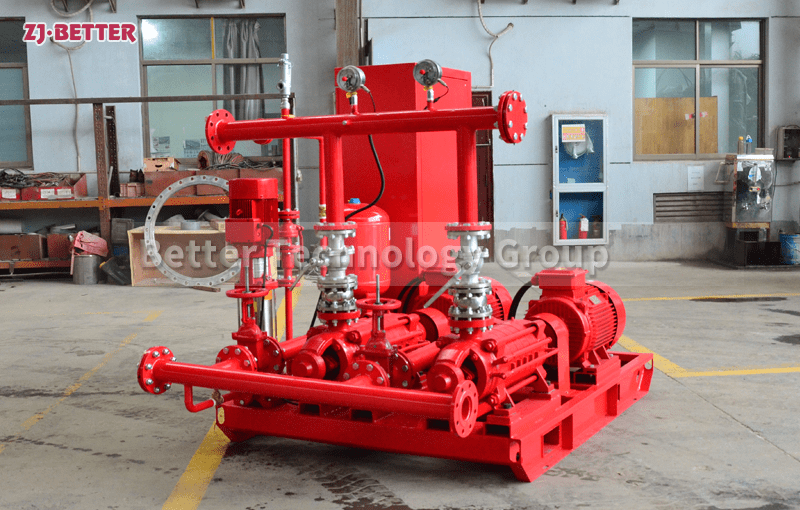

EDJ fire fighting package set is composed of diesel fire pump, electric pump, jockey pump.

Electric pump can choose single-stage pump, horizontal split case pump, end suction pump, multistage centrifugal pump, vertical turbine pump which are made of cast iron or stainless steel. Regarding to the impeller, we also could choose the bronze impeller.

Diesel fire pump, the flow is same as the electric pump. The diesel engine is combined by high elastic coupling or universal joint connection. The diesel fire set also includes fuel tank, water tank, fan, control panel and other components.

Jockey pump which is horizontal or vertical. Normally, it has the characteristics of small flow and higher head (more10-15m head than the electric pump and diesel pump).

For pump testing, there are different standards for different types of pumps.

For Centrifugal Pumps, Mixed Flow Pumps, Axial Flow Pumps and Vortex Pumps, the Standard is GB/T3216《Test methods for centrifugal pumps, mixed flow pumps, axial flow pumps and vortex pumps》

For fire pumps there are two Standard, for NON-UL fire pump, we use GB6245-2006 《FIRE PUMP》, this is also used for domestic CCCF certificate

For UL listed fire pump, the testing Standard is UL448, which is only used for UL LISTED FIRE PUMP

The submersible pump standard is GB/T12785《Submersible electric pump test method》