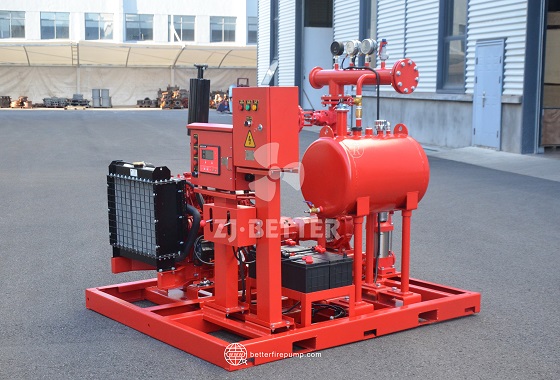

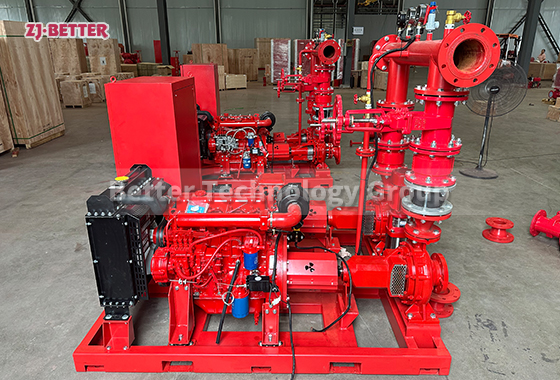

Design Features of Diesel Fire Pump Sets with Enhanced Protection and Cooling Performance

This article focuses on analyzing the advantages of diesel fire pump units that combine protection and heat dissipation performance, particularly their enclosed structural design, efficient heat dissipation system, stable power output, and continuous water supply capacity. These units are suitable for outdoor installation and fire water supply systems in complex environments.

In modern fire protection systems, diesel fire pump units are crucial equipment for providing reliable fire water sources in emergencies. Their design directly impacts their operational stability and safety in complex environments. Diesel fire pump units that balance protection and heat dissipation are a mature product solution developed to address the practical needs of high temperatures, high loads, continuous operation, and diverse installation environments. They exhibit significant advantages in structural design, performance, and long-term reliability. Firstly, from an overall structural design perspective, this type of diesel fire pump unit typically employs a closed or semi-closed protective structure, rationally integrating the diesel power system, fire pump body, coupling, and control components onto a robust base. Key components are effectively protected by metal protective covers or an integrated chassis, preventing damage from rain, dust, debris, and external impacts, and significantly enhancing the equipment’s adaptability to outdoor or harsh environments. This protective design is particularly important for fire pump units that require long-term outdoor installation or are located near industrial production areas, effectively reducing the interference of environmental factors on equipment performance. Meanwhile, the protective structure fully considers heat dissipation requirements during the design process. Through the rational layout of air inlets, outlets, and heat dissipation channels, the heat generated by the diesel engine during high-load operation can be dissipated in a timely manner, preventing power loss or component damage due to heat accumulation. The cooling system is typically equipped with a high-efficiency radiator and fan, which can maintain the engine and pump body within a reasonable operating temperature range under continuous operation, ensuring a stable water supply for an extended period during a fire. In terms of performance, the diesel fire pump unit’s hydraulic design emphasizes a balance between high head and large flow rate. Through optimized impeller structure and flow channel design, the pump unit can still output stable pressure and sufficient water volume under complex pipe network conditions, meeting the water needs of various fixed fire protection systems such as fire hydrant systems and automatic sprinkler systems. Under high-temperature or continuous operation conditions, stable heat dissipation performance provides a reliable guarantee for hydraulic output, preventing the pump unit from experiencing efficiency decline or unstable operation due to excessive temperature rise. As the core of the entire unit, the power system also occupies an important position in the protection and heat dissipation design. Diesel power features independent power supply and strong load adaptability, and can still start and operate quickly in the event of a mains power outage or power system damage. A sophisticated heat dissipation system ensures that the power system continuously outputs stable speed and torque under high load conditions, providing reliable drive for the fire pump. The protection design is also reflected in the safety protection of critical moving parts and electrical components. Through reasonable isolation and protection measures, the impact of the external environment on the control system and sensing devices is reduced, improving the overall system safety and stability. For fire-fighting equipment that needs to operate for a long time, good protection performance can significantly reduce the risk of failure due to environmental corrosion and extend the equipment’s service life. Ease of maintenance and use is also one of the important advantages of this type of diesel fire pump unit. Under the design concept of emphasizing both protection and heat dissipation, the unit structure usually reserves sufficient inspection space and maintenance channels, making daily inspection, maintenance, and component replacement operations more convenient, helping users to complete necessary maintenance work without affecting the overall system operation. Through reasonable modular design, the equipment can maintain good condition during long-term operation, reducing downtime and improving the overall reliability of the fire-fighting system. From an application perspective, diesel fire pump units that balance protection and heat dissipation performance are widely applicable to commercial buildings, industrial plants, warehousing and logistics centers, data centers, and various infrastructure projects, especially suitable for locations with high requirements for equipment operating environment or requiring outdoor installation. In these application scenarios, the equipment not only needs to have good fire water supply capacity but also must be able to cope with complex and changing environmental conditions. Improved protection and heat dissipation performance are key to ensuring its long-term stable operation. Overall, these diesel fire pump units, through systematic design in structural protection, heat dissipation systems, hydraulic performance, and power output, achieve stable operation under complex environments and high load conditions. This not only improves the reliability and safety of fire water supply but also provides users with a highly adaptable, long-lasting, and cost-effective fire protection equipment solution, making it a valuable and important product type in modern fire protection engineering.