In today’s increasingly complex industrial environments, fire safety is a paramount concern for both plant operators and safety engineers. Particularly in large-scale outdoor facilities such as oil refineries, chemical plants, power stations, logistics hubs, and storage depots, the need for reliable, autonomous, and high-performance fire suppression systems has never been greater. Among the various solutions available on the market, the highly integrated diesel fire pump system stands out as a top-tier option, offering powerful performance, easy deployment, long-term durability, and unmatched adaptability across challenging working conditions.

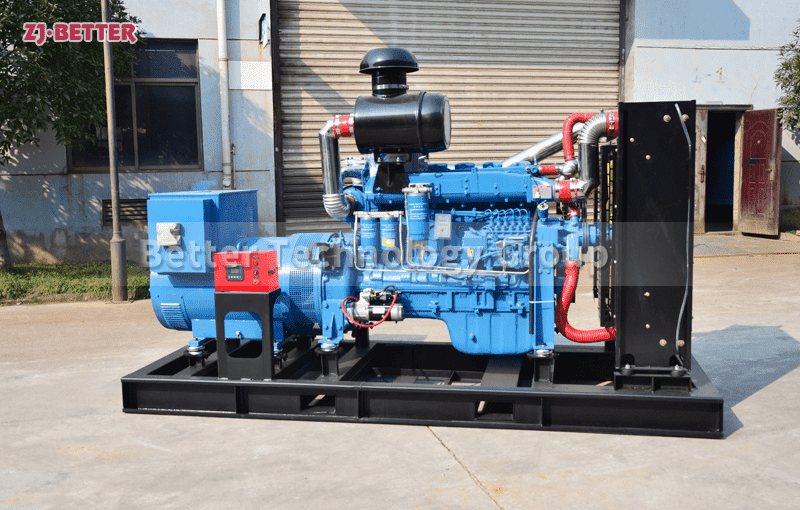

At the heart of this diesel fire pump system is a robust diesel engine, engineered for continuous heavy-duty performance. Unlike electric-driven fire pumps which depend on external power supplies, this system offers independent power generation through its integrated engine, making it ideal for remote installations or regions prone to power outages. The engine’s output is precisely matched with the pump’s hydraulic demands, ensuring optimal fuel consumption, consistent water pressure, and rapid response during emergency situations. Equipped with advanced fuel injection systems and air intake structures, the engine delivers smooth start-up, stable rotation speed, and minimal vibration, even under full-load operation.

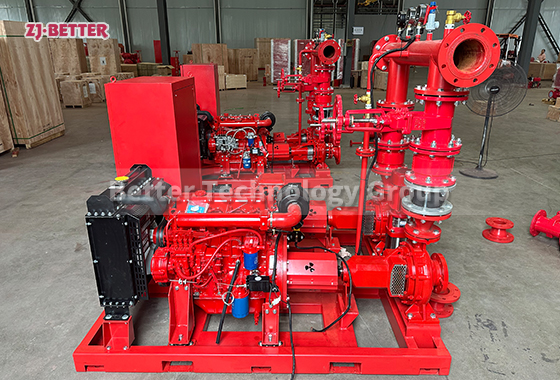

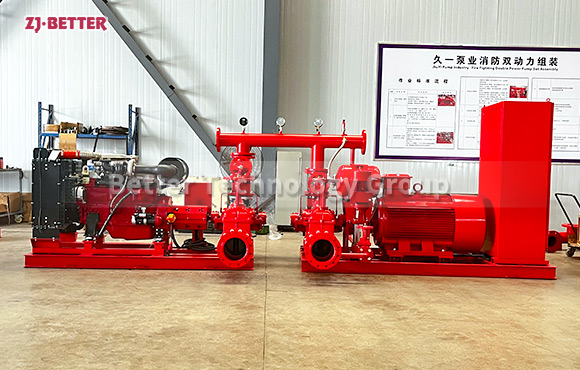

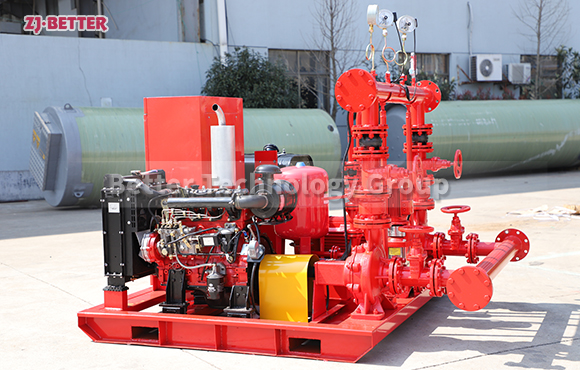

One of the standout advantages of this system is its high degree of integration. The fire pump, diesel engine, control cabinet, fuel tank, battery starting system, and all necessary piping and instrumentation are pre-mounted on a single base frame. This modular skid-mounted design significantly reduces installation complexity and on-site commissioning time. The system is delivered as a plug-and-play package—upon placement and connection of the outlet and inlet pipes, the unit is ready to operate. This makes it particularly suitable for outdoor industrial environments where installation windows are tight and operational continuity is crucial.

From a hydraulic performance perspective, the system employs a horizontal centrifugal pump capable of delivering high flow rates and pressures. The pump body, impeller, and shaft are constructed from corrosion-resistant materials, ensuring longevity even when used with chemically treated or sea water. Its axial suction and radial discharge configuration ensures efficient water delivery and reduced hydraulic losses. Additionally, the pump design incorporates a mechanical seal system and anti-leakage technology to minimize maintenance demands and increase operational safety.

The control system is another key component enhancing this fire pump’s reliability. Housed in a weatherproof cabinet, the electronic control panel offers intelligent automatic start-stop logic, fault detection, system diagnostics, and remote monitoring capabilities. Through sensors integrated into the engine and pump, the system can detect critical events such as over-speed, low oil pressure, high water temperature, or failure to start, and respond with appropriate alarms or automatic shutdowns. The user interface includes a digital display, status indicators, and programmable settings that allow operators to configure system behavior according to specific site requirements. For even greater operational efficiency, the system can be linked with building management systems (BMS) or SCADA networks to support real-time data exchange and centralized monitoring.

Another notable feature of the diesel fire pump system is its exceptional environmental adaptability. Designed for outdoor use, the entire assembly is built on a high-strength steel base frame coated with anti-rust paint and vibration-isolation mounts. All external connections are sealed against water ingress, dust, and UV exposure. The system can operate under extreme temperatures, with optional pre-heaters, engine cold start systems, and protective enclosures available for use in sub-zero environments. Ventilation and cooling are optimized through a high-capacity radiator, ensuring reliable thermal management during continuous operation.

Fuel autonomy is a critical consideration in outdoor fire pump applications, and this system addresses it with a generously sized fuel tank integrated into the skid base. The tank is sized to support continuous pump operation for over 8 hours at full load, depending on the engine model and configuration. A fuel level sensor is included to monitor reserves and issue alerts when refueling is necessary. Optional double-wall tanks, leak detection sensors, and external refueling ports can be added to comply with specific environmental or safety regulations.

From a maintenance standpoint, the diesel fire pump system is engineered for ease of service. All core components—engine, pump, filters, battery, and instrumentation—are positioned for direct accessibility. Quick-connect terminals, removable panels, and a detailed user manual further facilitate routine inspection and preventive maintenance procedures. Many models also feature a data logging function, recording operational parameters for later diagnostics and performance optimization.

The versatility of this system extends across multiple industrial sectors. It can be deployed as the main fire pump unit in fixed installations, or serve as a portable emergency backup system. Its autonomous operation and rugged build make it well-suited for temporary facilities, construction sites, pipeline projects, or military bases. The diesel-driven configuration is particularly favored in offshore and remote environments where electric power is unstable or unavailable.

Safety compliance is another major benefit. The system is designed to meet international standards such as NFPA 20 (National Fire Protection Association), UL/FM (Underwriters Laboratories/Factory Mutual), and local codes where applicable. Pressure relief valves, non-return valves, pressure gauges, and flow switches are pre-installed to guarantee operational stability and safety. Optional testing headers and drain lines facilitate weekly or monthly performance tests as mandated by regulatory authorities.

In summary, the highly integrated diesel fire pump system offers an ideal combination of performance, convenience, durability, and adaptability for outdoor industrial firefighting applications. Its self-contained nature, coupled with robust engine power and intelligent controls, ensures rapid response and long-lasting reliability. The modular design simplifies logistics and installation, while its proven hydraulic and mechanical components guarantee consistent high-pressure water delivery. Whether deployed as a permanent solution or mobile firefighting unit, this system is engineered to protect life, assets, and infrastructure in the most demanding environments. With its outstanding balance of functionality, ease of use, and regulatory compliance, it rightfully earns its reputation as the top choice for outdoor industrial fire protection.