Why Towable Fire Pumps Are Ideal for Emergency Firefighting Operations

Trailerable fire pumps boast high mobility, large flow rate, high head, and wide applicability, enabling rapid deployment and stable operation in scenarios such as fire water replenishment, emergency rescue, and flood control and drainage. This article provides an in-depth introduction to their structural advantages, power performance, application scenarios, and maintenance characteristics, offering a comprehensive reference for selecting high-performance mobile fire pumps.

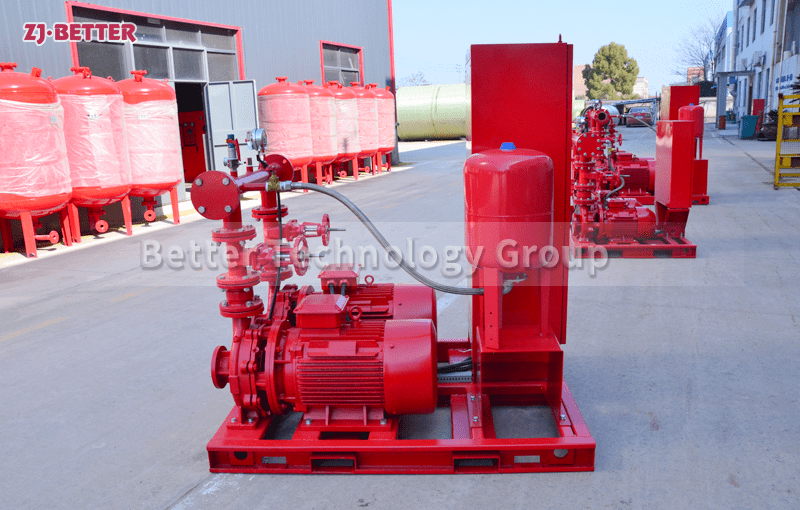

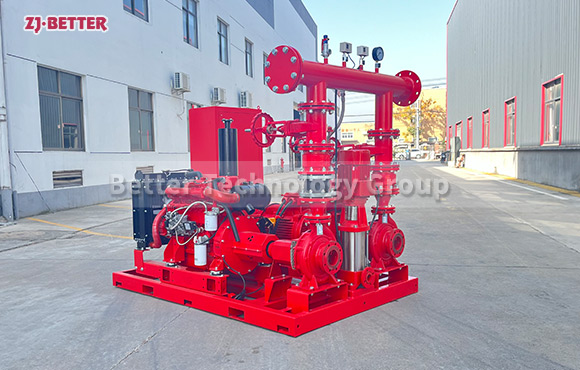

Trailer-mounted fire pumps, as a highly flexible and practical core component of modern emergency firefighting equipment systems, have gradually become the preferred equipment for various fire departments, industrial enterprises, warehousing and logistics centers, municipal units, and large-scale engineering projects in scenarios such as sudden fires, fire water replenishment, and flood control and drainage, thanks to their multiple advantages including convenient mobility, powerful performance, wide adaptability, and high reliability. Their unique trailer-mounted design allows the equipment to be quickly towed to the scene by ordinary vehicles, effectively overcoming the shortcomings of traditional fixed fire pumps, which are limited by installation location and have a slow response speed. This provides extremely high efficiency and flexibility for emergency rescue in complex environments. The core advantage of trailer-mounted fire pumps is primarily reflected in their powerful mobility. Due to their trailer chassis structure and robust frame with large tires, they maintain stable traction and rapid mobility on urban roads, factory roads, and even slightly undulating construction areas. In emergency situations, the trailer-mounted structure allows the equipment to be attached and deployed immediately within minutes, significantly improving the speed of on-site rescue response. Compared to fixed pumping stations that require lengthy preparation times, mobile fire pumps are better suited for multi-point operations, high-frequency dispatching, and cross-regional support missions. Furthermore, trailer-mounted fire pumps are typically equipped with high-power diesel engine power systems. Fuel-driven systems offer high stability and strong load capacity, maintaining high head and high flow rates to meet the stringent requirements of continuous water supply in large-scale scenarios. Their power systems feature rapid start-up, strong load adaptability, low fuel consumption, and high anti-interference capabilities, ensuring continuous and stable operation even in environments without electricity, on construction sites in the field, or in areas far from municipal water supplies. This is particularly important for the continuity and stability of firefighting operations, as water supply interruptions during firefighting or water replenishment often have serious consequences, and diesel-driven systems effectively avoid the risk of equipment downtime due to power supply fluctuations. In terms of performance, trailer-mounted fire pumps typically employ a high-efficiency pump body structure. Through optimized impeller design, pump chamber flow channels, and sealing systems, they improve water intake capacity and output efficiency, enabling rapid water priming and stable water supply within a short time. Its strong suction performance makes it particularly suitable for drawing water from temporary natural water sources such as rivers, lakes, canals, and collection ponds. This strong adaptability to water source environments allows it to operate freely in various types of areas, including mountainous regions, towns, ports, and industrial and mining areas, truly achieving wide-area application without water source limitations. Furthermore, the pump body is made of corrosion-resistant and wear-resistant materials, ensuring that the equipment maintains high-performance output even under long-term high-load operation. Trailer-mounted fire pumps demonstrate excellent adaptability in various complex working conditions, which is one of the key reasons for their popularity. Whether it’s a large-scale building fire requiring long-term, high-flow water supply, a sudden chemical fire requiring long-distance delivery of extinguishing agents, or fire-fighting water replenishment operations in remote areas, this type of equipment can handle it all. Especially when urban fire pipeline pressure is insufficient, or when large commercial areas or high-rise buildings require pressurized water supply, trailer-mounted equipment can be quickly connected to the system as a temporary booster unit, providing stable pressure and flow, ensuring that the overall water supply capacity of the fire pump group is not affected. Trailer-mounted fire pumps also have significant advantages in flood control and drainage. Due to its strong suction and large flow rate, the trailer-mounted fire pump can quickly pump out accumulated water in scenarios such as heavy rain, floods, waterlogged underground garages, and factory drainage. Its mobility allows the equipment to quickly enter narrow streets, underground space entrances, construction sites, and other areas, significantly improving drainage efficiency. In response to large-scale flooding disasters caused by extreme weather, multiple units working together can form a mobile pumping station, thus meeting the needs of large-area, deep-water, and high-volume drainage operations. It is worth mentioning that the ease of operation of trailer-mounted fire pumps is also a major factor in their popularity. The equipment is typically equipped with intelligent control systems, intuitive operating interfaces, and automatic monitoring and protection programs, enabling operators to quickly learn how to use them. Many units have automatic shutdown protection, abnormal alarms, and automatic pressure stabilization functions, reducing human error and improving operational safety. For businesses or fire teams, a lower operating threshold means lower training costs, more flexible personnel deployment, and enhanced overall emergency response capabilities. In terms of maintenance, the structural design of trailer-mounted fire pumps fully considers future maintenance needs. The equipment typically employs a modular layout, with a rational distribution of the power system, pump system, piping system, and control system, allowing maintenance personnel to easily inspect and perform maintenance. Replacement of routinely worn components such as filters, oil, belts, and seals is also very convenient, ensuring high reliability over long-term use. Furthermore, the trailer chassis and structural components undergo corrosion-resistant and rust-proofing treatments to guarantee structural stability even under prolonged outdoor use. The safety of towable fire pumps is equally crucial. The equipment is usually equipped with multiple safety features, such as engine high-temperature protection, oil pressure protection, pump overload protection, backflow prevention devices, and inlet/outlet pressure monitoring, ensuring safe operation even under extreme conditions. Many units also support remote monitoring and real-time data output, allowing managers to promptly grasp the operational status and achieve more scientific and rational scheduling and management. In terms of durability, trailer-mounted fire pumps are manufactured using high-strength steel structures, thickened pump bodies, and pressure-resistant piping systems. Combined with meticulous manufacturing processes and rigorous testing procedures, this ensures the equipment has a long lifespan and high reliability, maintaining stable output even under conditions of continuous operation, frequent dispatching, outdoor exposure, and cold environments. Its seismic and impact-resistant design effectively copes with vibrations during road transport, preventing equipment damage and extending its overall service life. For large industrial enterprises, warehousing and logistics centers, ports, and municipal engineering departments, trailer-mounted fire pumps are not only emergency equipment but also crucial for ensuring production safety, enhancing emergency response capabilities, and reducing accident risks. The equipment’s rapid deployment capability means that rescue operations can be initiated in the shortest possible time after an emergency occurs, significantly reducing the possibility of fire spread. Its powerful output, high flow rate, wide applicability, and adaptability to various operating conditions provide enterprises with greater flexibility and assurance when developing emergency plans. With the continuous development of modern fire protection systems, the demand for highly mobile, multi-purpose, and efficient fire protection equipment continues to increase. Trailer-mounted fire pumps, with their comprehensive advantages in flexibility, performance, reliability, durability, and environmental adaptability, have become essential equipment in the standardized configuration of many fire departments and enterprises. Under the future trend of intelligent fire protection equipment development, trailer-mounted fire pumps will gradually integrate with digital monitoring, IoT management platforms, and remote dispatch systems to provide more precise and efficient intelligent support for emergency rescue. As a professional piece of equipment integrating mobility, performance, and reliability, trailer-mounted fire pumps provide strong technical support for various emergency scenarios and are an indispensable piece of equipment in modern fire protection and emergency management systems.