The Driving Force Behind Mobile Fire Systems: A Comprehensive Analysis of Diesel Fire Pump Applications

Diesel engine-driven fire pump units provide independent power, high-efficiency output, and flexible deployment, making them essential in emergency response and off-grid firefighting scenarios. This article explores structure, performance, applications, and market value to enhance fire safety and project competitiveness.

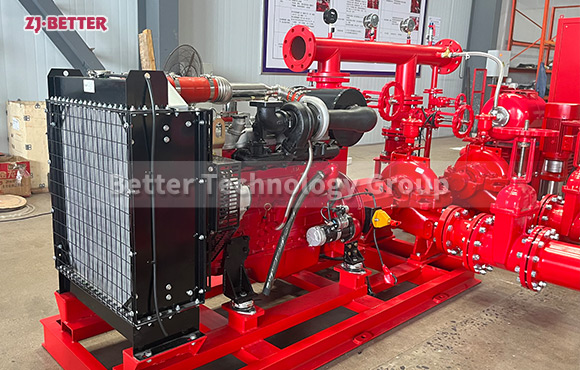

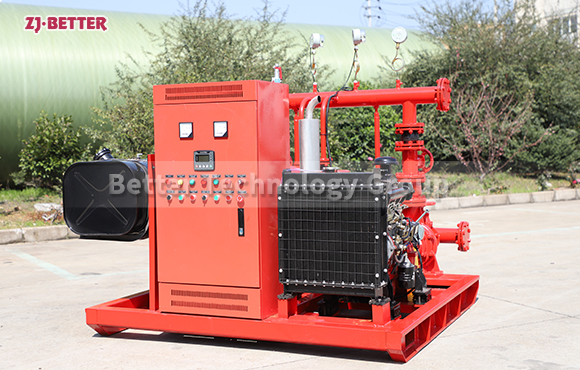

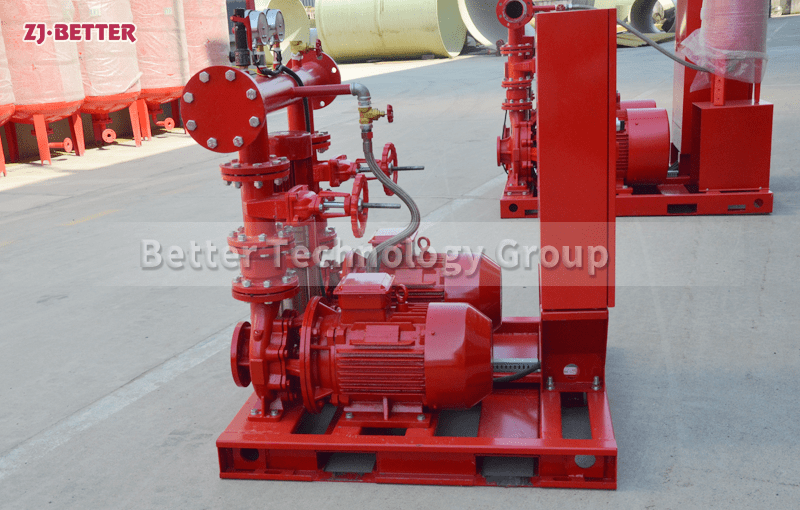

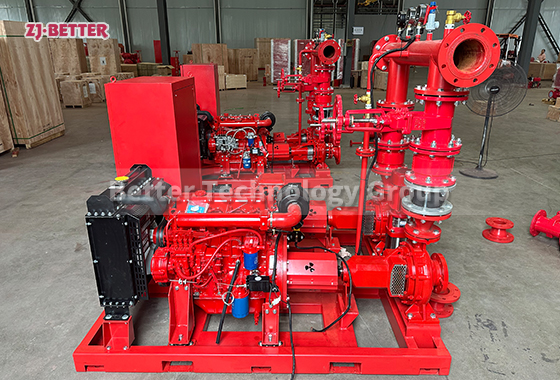

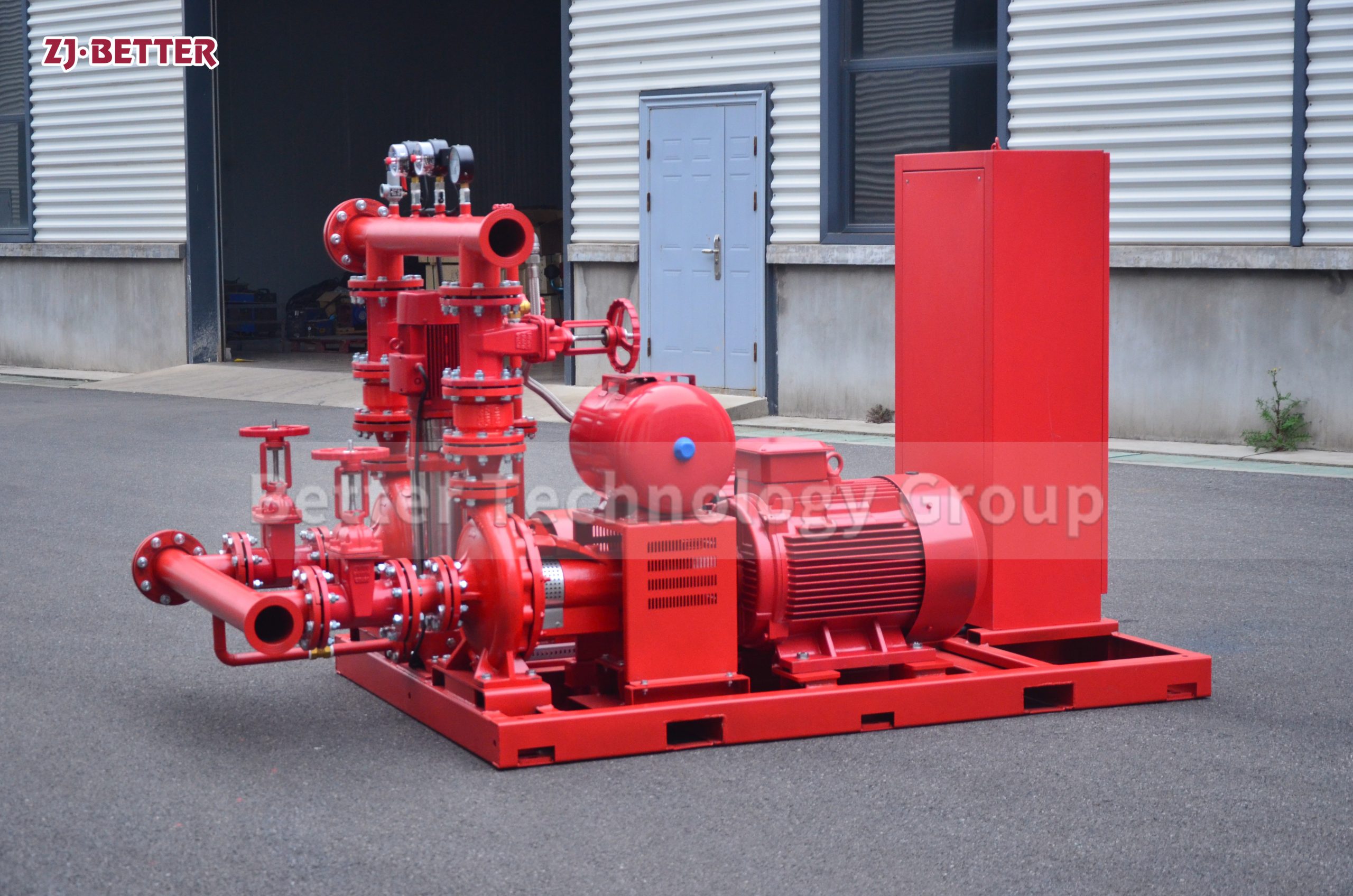

In today’s environment of frequent fires and increasing demands for disaster response, traditional fixed fire suppression systems are no longer sufficient to meet the emergency needs of diverse scenarios and sudden fire incidents. This is particularly true in industrial parks, remote areas, large outdoor venues, highways, oil and gas facilities, temporary structures, and regions with underdeveloped power infrastructure, where stable, powerful, and convenient fire water supply has become a critical component of project safety. Among various firefighting equipment, diesel-driven fire pump sets are increasingly becoming the core power units in mobile firefighting systems. Their outstanding independent operation capability, flexible deployment methods, powerful power output, and high system integration make them an indispensable component of the current emergency firefighting support system. Diesel-driven fire pump sets utilize high-performance diesel engines as their power source, combined with high-efficiency horizontal centrifugal pumps, end-suction pumps, or multistage pumps as hydraulic components. These are directly driven via flexible couplings to achieve continuous water supply with high power, high head, and large flow rates. Unlike electric pump systems, which are constrained by power supply availability, diesel pump sets can operate stably under conditions of no grid power, power outages, or complex disaster scenarios. Especially during power outages or unforeseen fire incidents, the self-powered advantage of diesel pump sets is fully demonstrated, providing the most reliable water supply assurance at the scene. Additionally, pump sets are typically equipped with fuel tanks, vibration-damping bases, intelligent control cabinets, cooling systems, and emergency start batteries to ensure efficient startup and continuous operation even in harsh environments. In terms of structural design, modern diesel fire pump sets emphasize system integration. The entire unit is typically mounted on a corrosion-resistant, high-strength chassis, combined with vibration absorption, noise reduction, cooling, and maintenance通道 designs to enhance overall operational stability and service life. Some products also integrate mobile chassis and trailer systems, transforming into mobile fire pump trucks suitable for emergency response or cross-regional deployment. The power source typically uses diesel engines from well-known domestic and international brands (such as Cummins, Weichai, Yuchai, and Shangchai), whose reliability, fuel efficiency, and durability have been rigorously tested and market-validated, supporting continuous operation of the pump set for over 8 hours. The control system primarily employs PLC programmable logic controllers, supporting one-button startup, self-diagnosis, remote monitoring, and multiple alarm functions, providing operators with a highly intelligent operational experience. In practical applications, diesel-driven fire pump sets have been widely deployed in municipal water supply backup systems, petrochemical terminals, aviation zones, water conservancy projects, and outdoor engineering camps. In these environments, users face common challenges such as unstable power supply, complex water source allocation, and challenging terrain that makes it difficult to install fixed fire protection systems. The flexibility and emergency response capabilities of diesel fire pump sets are key to addressing these issues. This equipment can not only operate as an independent main pump but also be connected in parallel with an electric pump to form a “dual-power firefighting system,” creating a multi-redundant firefighting mechanism with mutual backup and switching capabilities, thereby significantly enhancing the overall reliability and safety level of the firefighting system. Additionally, driven by the trend toward green and environmentally friendly practices, some diesel pump sets support optional diesel engines compliant with National IV and National V emission standards. They also reduce emissions by optimizing the combustion system and exhaust treatment modules, providing sustainable support for environmentally friendly fire protection infrastructure. In terms of installation and maintenance, diesel fire pump sets are easy to install, quick to deploy, and have low requirements for infrastructure, making them particularly suitable for short-term projects, temporary fire protection upgrades, and scenarios with significant seasonal demand fluctuations. Maintenance is also simplified due to the product’s straightforward structure and clear modules, allowing users to quickly perform maintenance and component replacements, resulting in relatively low overall operating costs. In international markets, diesel-driven fire pump sets are highly favored, particularly in regions such as the Middle East, Southeast Asia, Africa, and Latin America, where power stability is not a top priority or where emergency response is the primary focus. Their ability to operate as independent workstations, high cost-effectiveness, and rapid response capabilities are key factors influencing import customers’ decisions. Combined with the customization capabilities provided by the brand website (www.119pump.com), this product supports customization of various specifications, multiple flange standards, intelligent remote start, automatic refueling systems, and automatic shutdown in case of overheating, meeting the complex usage requirements of customers in different industries. From a technological development perspective, diesel fire pump sets will continue to evolve toward intelligent control, remote management, environmental protection and energy efficiency, and modular integration. For example, integrating 5G IoT technology to enable remote monitoring and maintenance management of pump set operational status; using AI algorithms to predict equipment failures in advance and warn of maintenance cycles; or achieving more compact and lightweight engineering optimizations in the unit structure to reduce transportation and scheduling costs. It is foreseeable that with the continuous development of smart fire protection, green buildings, and emergency rescue systems, diesel-driven fire pump sets will continue to play an irreplaceable core power role in various complex and extreme environments. It is not merely a pump but a critical piece of equipment for addressing fire risks and ensuring the safety of personnel and property, embodying the reliability and diverse capabilities of modern fire protection systems. Choosing high-performance diesel-driven fire pump sets means selecting emergency water supply assurance that prioritizes safety, stability, and professionalism.