Reliable Solutions for Harsh Conditions: Engineering Adaptability of Diesel-Powered Fire Pumps

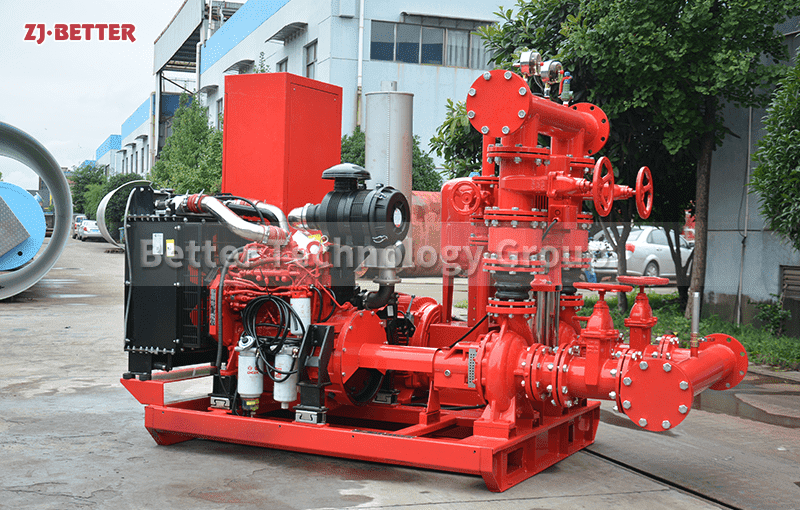

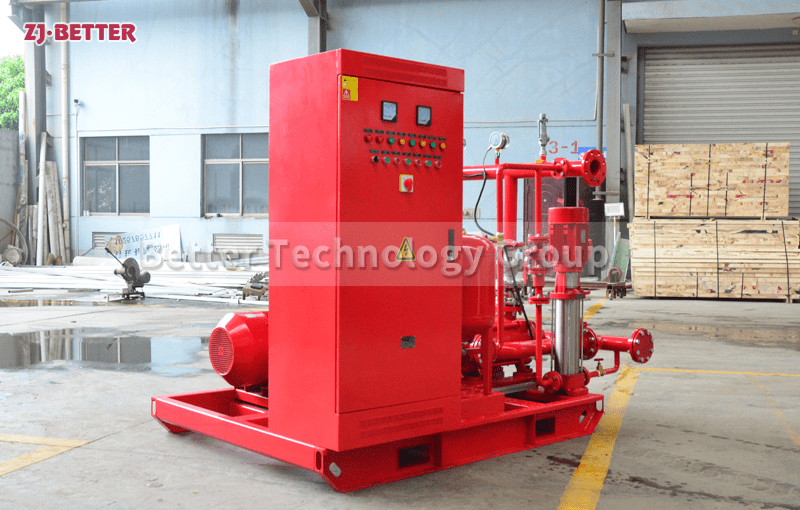

Diesel engine fire pump systems are designed for power-deficient and extreme environments, offering independent operation, strong corrosion resistance, and intelligent control. Ideal for oil fields, ports, and industrial projects, they ensure reliable emergency fire water supply.

In the construction of modern fire protection systems, ensuring the stable operation of equipment under extreme environmental conditions has become a significant challenge for various engineering projects. This is particularly true in complex scenarios such as remote mountainous areas, offshore oil and gas fields, ports and terminals, industrial chemical zones, and desert regions with extreme heat or high-altitude cold climates, where insufficient or unstable power supply frequently occurs, severely limiting the operational efficiency and emergency response capabilities of conventional fire pump systems. In such situations, diesel-powered fire pump systems emerge as an independent, reliable, and efficient water supply solution, demonstrating exceptional engineering adaptability and practical performance. These systems, driven by diesel engines, are designed to international standards, with core power units featuring high-performance industrial diesel engines. They possess robust instantaneous startup and sustained operation capabilities, enabling them to independently complete firefighting water supply tasks without external power sources, thereby achieving the goal of “self-sufficiency” in emergency rescue operations. Its modular integrated structure design makes the entire system more convenient and efficient during transportation, hoisting, positioning, and commissioning, significantly reducing initial construction costs and project timelines. Additionally, this series of diesel fire pumps features a heavy-duty welded base platform, ensuring structural stability and strong seismic resistance, enabling reliable operation in unstable geological conditions or complex surface environments. The pump components primarily adopt horizontal single-stage or horizontal split-case double-suction structures, featuring advanced hydraulic models, smooth flow channels, and high operational efficiency, making them suitable for applications requiring high flow rates, long distances, and high head water supply. For special operating conditions such as high cold, dust, high temperature, or salt fog, the equipment housing and key components can be optionally equipped with special corrosion-resistant, freeze-resistant, and protective materials. Additionally, auxiliary systems such as automatic constant-temperature heaters, anti-sand filters, and intake heaters can be installed to ensure the diesel engine starts and operates smoothly in any season. Additionally, the diesel pump is equipped with an intelligent electronic control system, integrating an LCD display screen and a multifunctional control module, which displays real-time key data such as pressure, speed, temperature, and operating time. It also supports remote start, remote monitoring, and historical data recording functions, fully meeting the management requirements of modern intelligent fire protection systems. From a control logic perspective, diesel fire pump sets typically feature a dual system of electric start batteries and manual emergency start, ensuring reliable ignition under any circumstances. For critical industry users such as telecommunications, ports, and substations, the system can be customized with advanced features such as remote fault diagnosis, SMS alerts, and automatic inspections, significantly enhancing fault response capabilities and equipment safety. Additionally, the entire diesel engine fire pump system supports multiple standard interface formats, including GB6245 standards, UL/FM standards, and EN12845 standards, facilitating localized use and compliant integration for projects in different countries and regions. In terms of energy consumption control, the diesel engine adopts a high-pressure common rail fuel system and turbocharging technology, achieving high fuel utilization and excellent energy efficiency. It maintains a low fuel consumption and low carbon emissions environmental operation mode during prolonged operation, meeting the technical requirements for energy conservation and emissions reduction in green buildings. Notably, the diesel engine pump set structure supports multi-unit parallel operation design, enabling automatic switching control logic between the main pump and standby pump based on system requirements, thereby enhancing the overall system’s redundancy and risk resilience. Actual case studies demonstrate that this product has performed exceptionally well in multiple “Belt and Road” key projects, successfully addressing extreme climatic conditions and power outages in scenarios such as the Nigeria Industrial Park, Iraq Oil Field Station, and Mongolia Mining Base, providing continuous and stable fire protection for the projects. Overall, diesel-powered fire pumps offer five significant advantages in terms of engineering adaptability: first, they are energy-independent, eliminating reliance on the power grid, and are suitable for complex environments such as wilderness and mountainous areas; second, they have a robust structure with excellent seismic resistance and corrosion protection, capable of withstanding harsh terrain and high-salt, high-humidity environments; third, they start quickly, ensuring rapid response during the initial stages of a fire and improving firefighting efficiency; Fourth, intelligent control systems support remote operation and multi-point coordination; fifth, strong adaptability with flexible modular design allows for customized configuration of pump units based on project requirements. In today’s environment where fire risks are increasingly complex and on-site conditions are highly variable, selecting a diesel-powered fire pump system that balances performance, stability, adaptability, and intelligent control has become a consensus among many engineering contractors and emergency management agencies. The “Better” series of diesel pump products, backed by high-quality materials, strict manufacturing processes, standardized assembly, and extensive field testing in real-world projects, has gained widespread recognition globally. Whether in airports, ports, power plants, petrochemical facilities, smart city development, or national key infrastructure projects, these products provide stable and efficient firefighting water supply support, offering a reliable solution for addressing fire challenges in extreme environments.