Diesel fire pumps are often available as backup

Diesel engine fire pumps are usually used as a backup facility, and will only start automatically when the electric water pump fails or the power is cut off when the fire signal comes. When equipped with an ultra-low pressure pump starting device, the matching electric pump control cabinet should also be equipped with an ultra-low pressure pump starting device, and the lower limit of pump starting should have a certain pressure difference. Of course, it is also possible to design a control system that is more suitable for customer needs according to customer requirements.

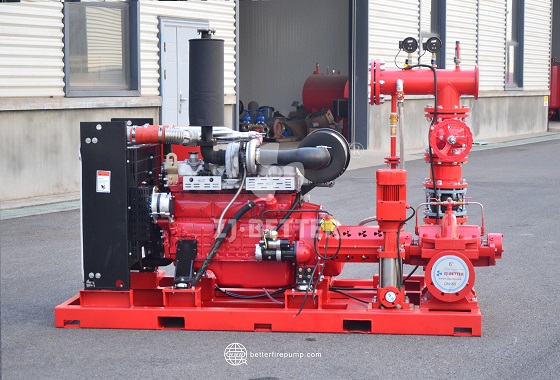

XBC diesel engine fire pump is a new product independently developed and produced by our company according to the market demand and applicable characteristics of domestic building fire pumps. Diesel engine fire pump series products have high efficiency, long operating life and high reliability (there is no failure of pneumatic seizure after a long period of inactivity), and are currently the first choice for pumps suitable for building nominal fire protection and sprinkler facilities in China. The product performance complies with GB6245 “Fire Pump Performance Requirements and Test Methods”, and has been tested by the National Fire Equipment Quality Supervision and Inspection Center, and the product has reached the domestic leading level. Diesel engine fire pumps can be used to transport clear water below 80°C without solid particles or liquids with physical and chemical properties similar to water. Under the premise of meeting the fire protection conditions, the requirements of the living and production water supply conditions are taken into account. The products can be used not only in independent fire water supply systems, but also in fire protection and domestic shared water supply systems, as well as in construction, municipal, industrial and mining, water supply and drainage, ships, field operations and other occasions.