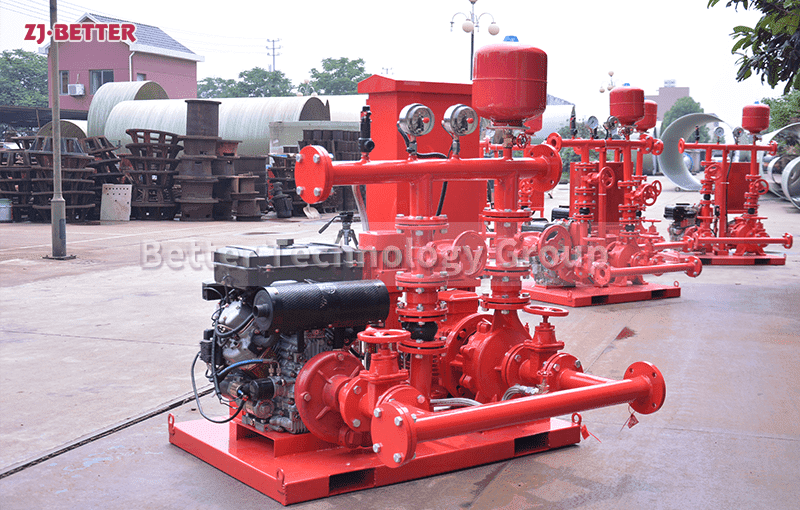

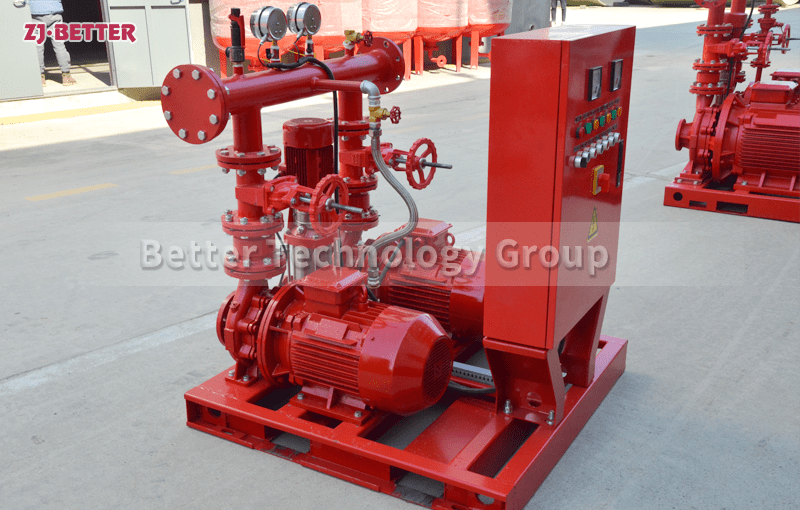

As the name suggests, fire pumps are used in fire protection. Fire pumps are imported products. They are divided into different types according to different classification methods. They are fully sealed, leak-free and corrosion-resistant. They are widely used in environmental protection, water treatment, fire protection, etc. It is used to pump all kinds of liquids, and it is an ideal pump and fire protection system for creating non-leakage, non-polluting civilized workshops and civilized factories. The pump types are similar, but the head and flow are different. The selection basis of the fire pump should be considered according to the process flow, water supply and drainage requirements, and other five aspects. The performance and technical conditions of the fire pump meet the requirements of the “Fire Pump Performance and Test Methods” standard.