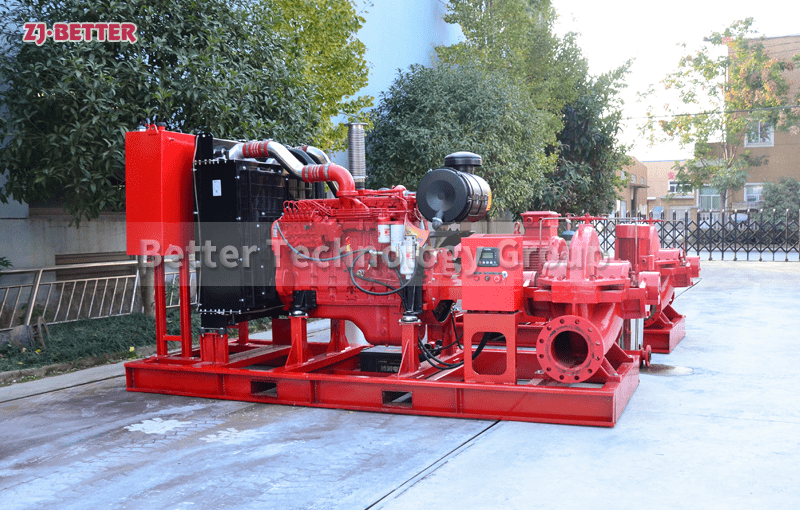

Precautions for import and export when installing fire pumps

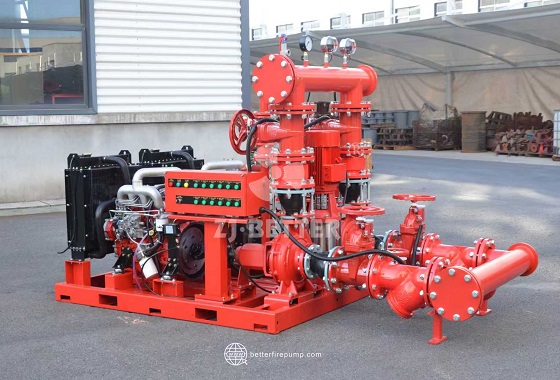

1. Export: All fire pump components should be carefully inspected and packed to ensure that they meet all applicable export laws and regulations. All components should be properly marked or labeled to be easily identified even in a foreign country.

2. Import: The importing country may require certain types of documents to be presented with the fire pumps. These documents may include an export permit, a commercial invoice, a packing list, or perhaps even an insurance policy. If exporting to a foreign country, a customs clearance may also be required.

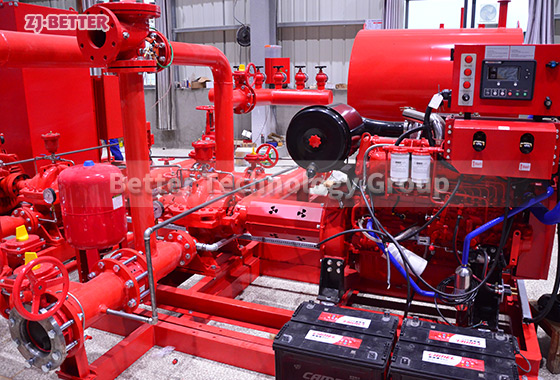

3. Regulatory Requirements: Fire pump components may fall under certain regulatory requirements, either imposed by the importing country, or by the country of origin. It is important to check with the relevant regulatory authorities to ensure that the equipment meets all applicable regulations.

4. Certification: Depending upon the type of pump being imported, or exported, certain certification may be required. Certification of fire pumps may include UL or ITU ratings, as well as other safety or performance criteria. It is important to comply with all such regulations to ensure the safety of the installed fire pump system.

1. Export: All fire pump components should be carefully inspected and packed to ensure that they meet all applicable export laws and regulations. All components should be properly marked or labeled to be easily identified even in a foreign country.

2. Import: The importing country may require certain types of documents to be presented with the fire pumps. These documents may include an export permit, a commercial invoice, a packing list, or perhaps even an insurance policy. If exporting to a foreign country, a customs clearance may also be required.

3. Regulatory Requirements: Fire pump components may fall under certain regulatory requirements, either imposed by the importing country, or by the country of origin. It is important to check with the relevant regulatory authorities to ensure that the equipment meets all applicable regulations.

4. Certification: Depending upon the type of pump being imported, or exported, certain certification may be required. Certification of fire pumps may include UL or ITU ratings, as well as other safety or performance criteria. It is important to comply with all such regulations to ensure the safety of the installed fire pump system.