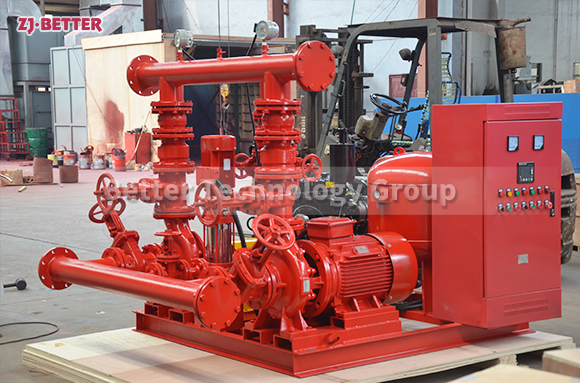

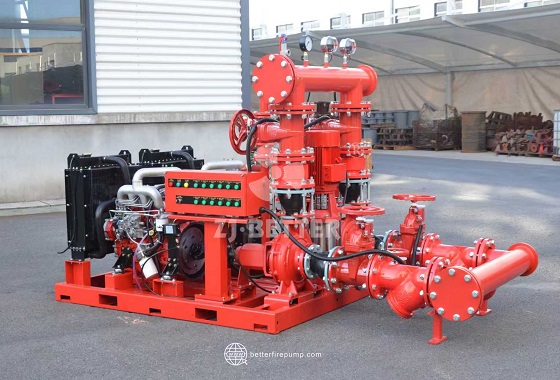

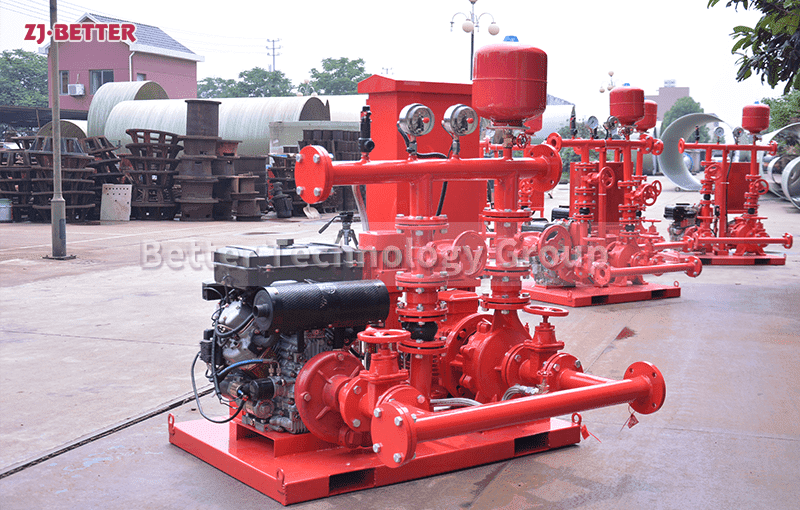

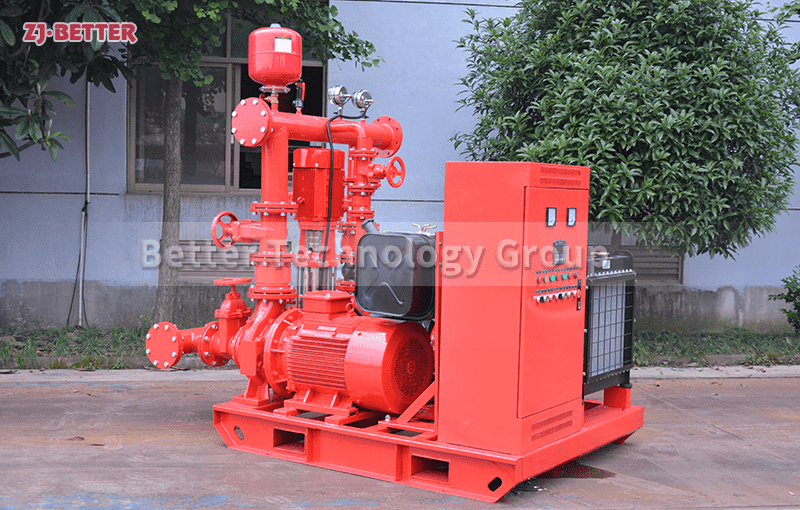

EE Multistage Fire Pump Set

Single-stage fire pumps have only one impeller, and multistage fire pumps can have two or more impellers. Because the pump core in them is different, the structure is different. The impeller of the multi-stage pump is more than that of the single-stage pump, which can achieve a larger head at the same flow rate. The multi-stage pump is the sum of the single-stage pumps, and the head and outlet pressure can be made very high.

The inlet and outlet of the multi-stage fire pump are on the same horizontal axis and have the same caliber specifications, so the loading and unloading is very convenient, and the floor space is small. The pump is fitted with a base for easy installation and increased pump stability. It is used to transport clear water without solid particles, liquids with physical and chemical properties similar to water. It is mainly used for pressurized water delivery in fire-fighting system pipelines, and is also suitable for industrial and urban water supply and drainage.

1. The pump has compact structure, small volume and beautiful appearance. Its structure determines the size of the installation area, and its center of gravity coincides with the center of the pump foot, thereby improving the stability and service life of the pump;

2. Advanced hydraulic model, high efficiency and good performance;

3. Smooth operation, low noise and high concentricity of components;

4. The shaft seal uses a high-quality mechanical seal, so the wear resistance is very good, there will be no leakage, and the service life can be extended.