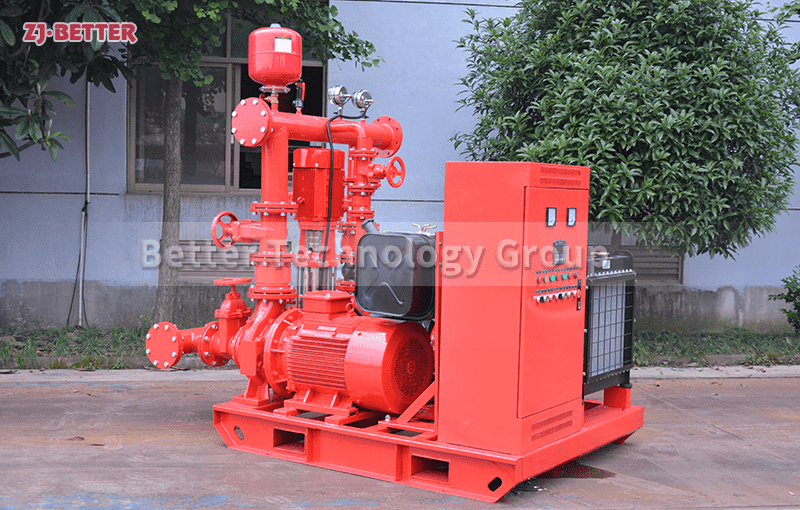

High Efficiency Diesel Engine Fire Pump Set

Diesel engine fire pumps are mainly suitable for fire water supply and foam fire extinguishing systems in petrochemical, natural gas, power generation, cotton and linen textiles, warehouses, airports, docks, high-rise buildings and other industries. It can also be used in occasions such as water ships, offshore oil tankers and fire fighting ships. The unit adopts imported diesel engine and fire pump. It has the characteristics of quick start, reliable water diversion, reasonable power reserve, stable operation, high degree of “three modernizations”, wide range of pressure and flow, etc. It is an advanced and reliable fire-fighting equipment.

Diesel engine fire pump is simple in structure, reliable in use, convenient in installation, high in efficiency, small in size, light in weight, and has direct drive and variable speed drive. When ordering, the model (power, speed) of the power machine should be specified in order to determine the specifications of the coupling or pulley. Seen from the diesel engine pump to the water pump inlet, the impeller generally rotates counterclockwise. Diesel engine fire pumps adopt advanced air-cooled four-stroke direct-injection diesel engine as the power system, with compact structure, lighter weight and strong power. The main application of diesel engine pump: agricultural drainage and irrigation, industrial drainage and other devices. The diesel engine pump can be selected according to the specific requirements of the head, flow rate and conveying liquid of the place of use.