Installation Efficiency and Operational Advantages of Skid Mounted Diesel Fire Pump Equipment

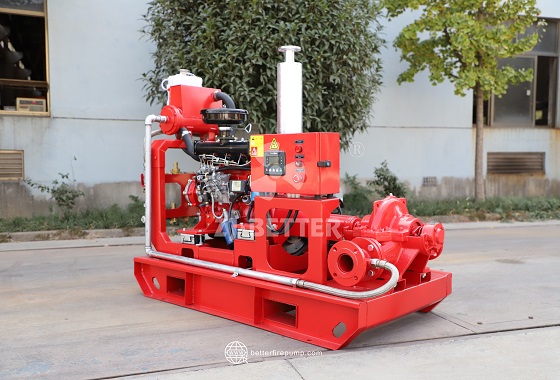

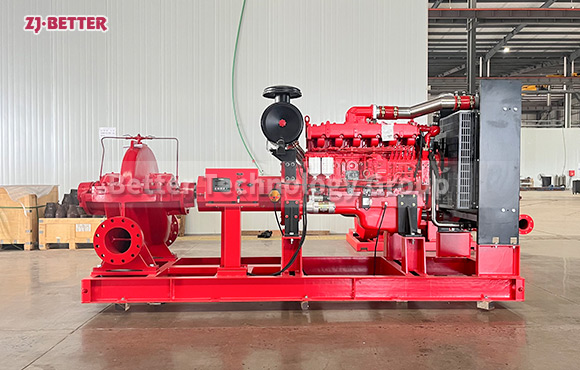

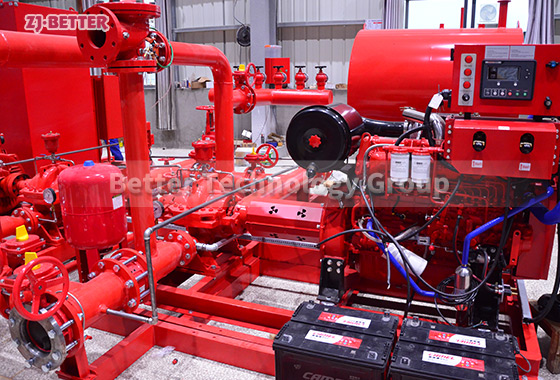

Skid mounted diesel fire pump systems designed for fast installation and reliable operation, featuring integrated structure, stable water supply, strong diesel power, and dependable performance for fixed and industrial fire protection projects.

The installation efficiency and operational advantages of skid-mounted diesel fire pumps are mainly reflected in their highly integrated design, strong adaptability, and stable performance for engineering applications. These fire pumps typically integrate the diesel engine, water pump, control system, fuel system, cooling system, and necessary piping accessories onto a steel base or skid frame. Assembly and commissioning are completed before delivery, allowing the equipment to be put into use on-site without complex installation. For fire protection projects, construction time and system reliability are crucial. Skid-mounted diesel fire pumps, through modular supply, significantly reduce on-site installation and commissioning time, avoiding problems such as alignment errors, piping mismatches, or inconsistent control logic caused by the dispersed installation of multiple devices, thus improving the overall operational stability of the system from the source. Diesel power, as a key drive for fire pumps, can operate independently even when mains power is unavailable or the power system is unstable. It is particularly suitable as a backup or primary power source for fixed fire protection systems, and has extremely high practical value in industrial parks, infrastructure projects, warehousing and logistics centers, and projects in remote areas. The skid-mounted design provides excellent overall rigidity. The engine and pump body are precisely aligned and fixed to the same base, effectively reducing vibration and noise levels during operation. It also minimizes the risk of fastener loosening due to long-term operation, which is especially important for fire-fighting equipment requiring extended service life. In terms of hydraulic performance, diesel fire pumps typically employ an optimized pump body structure, ensuring efficient output of flow rate and head under rated operating conditions. The smooth internal flow channels and minimal hydraulic losses help maintain stable pressure during long-term continuous operation, providing a reliable water source for the fire-fighting network. To adapt to the needs of different projects, skid-mounted diesel fire pumps offer high flexibility in parameter configuration. Selection can be based on network size, building height, and design standards, ensuring the equipment meets fire-fighting water requirements while avoiding energy waste due to over-configuration. The integrated control system is one of the key advantages of skid-mounted diesel fire pumps. The control cabinet is typically integrated with the pump unit, featuring automatic start-up, manual control, operation monitoring, and fault alarm functions. It can respond quickly to fire signals or detect abnormal system pressure, automatically activating the system and reducing the uncertainty caused by human intervention. For fire protection engineering, reliable start-up is a key indicator of equipment performance. Diesel fire pumps are specifically designed in terms of fuel supply, starting system, and speed control mechanism, maintaining good starting performance even in low temperatures or long standby conditions, ensuring rapid water supply in emergencies. The skid-mounted structure also facilitates equipment transportation and hoisting. The base has pre-drilled hoisting holes or forklift positions, allowing for complete movement of the equipment without disassembly, facilitating rapid on-site positioning and installation, which is particularly important in large projects or space-constrained machine room environments. Regarding operational stability, diesel fire pumps utilize high-strength pump shafts, wear-resistant seals, and reliable bearing configurations to effectively improve overall durability. They can withstand the mechanical loads from frequent testing and occasional long-term operation, reducing the probability of failure. The rational layout of the cooling and exhaust systems is also a crucial design consideration for skid-mounted diesel fire pumps. By optimizing the air ducts or water-cooling structure, the engine maintains a suitable operating temperature under high load, thus avoiding power attenuation or overheating shutdown and ensuring continuous and stable output from the fire pump during critical moments. Ease of maintenance is another major advantage of skid-mounted structures. All major components are centrally located, providing a clear maintenance space and simplifying routine maintenance and inspection, which helps reduce operating costs and improve equipment manageability. From a life-cycle perspective, skid-mounted diesel fire pumps excel in installation efficiency, operational stability, and long-term value due to their high integration, reliable power output, and adaptability to complex operating conditions. They not only meet the stringent safety and reliability requirements of fire protection engineering but also provide project owners with an efficient, time-saving, and risk-controlled fire water supply solution, occupying a vital position in modern fire protection systems.