Performance Analysis of Vertical Electric Fire Pumps for Industrial and Civil Buildings

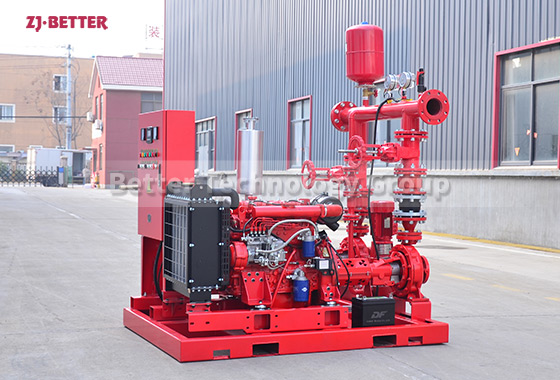

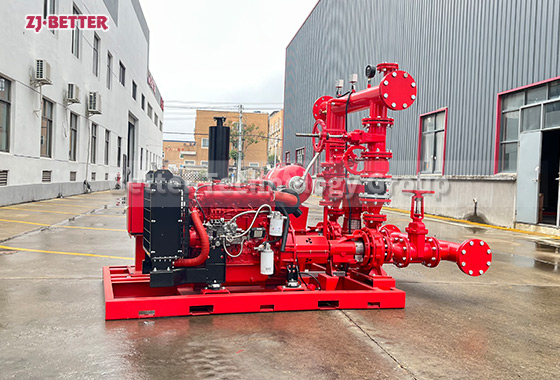

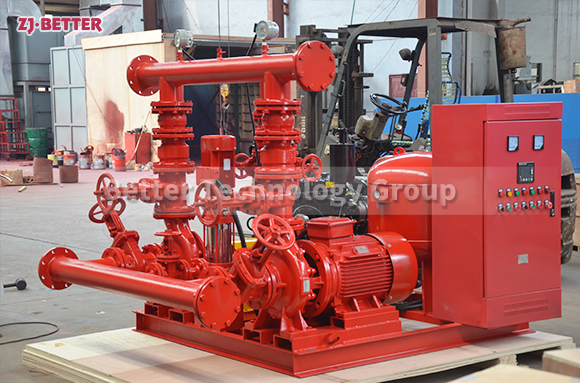

Vertical electric fire pumps are suitable for fire protection systems in industrial and civil buildings. They feature a compact structure, small footprint, rapid start-up, stable pressure output, and continuous water supply, providing a reliable fire water supply solution for sprinkler and fire hydrant systems.

Vertical electric fire pumps for industrial and civil buildings are key water supply equipment in fixed fire protection systems, primarily serving fire hydrant and automatic sprinkler systems. In emergency situations during a fire, they play a crucial role in rapidly establishing pressure and providing a continuous and stable water supply. These vertical electric fire pumps use an electric motor as their power source and feature a vertical structure design, resulting in a small footprint and flexible layout. They are particularly suitable for industrial plants, commercial buildings, high-rise residential buildings, and public facilities where pump room space is limited or multiple units need to be centrally located. The pump body is typically made of high-strength cast iron or ductile iron, possessing excellent pressure resistance and structural stability. It can operate for extended periods under high head and high flow conditions without performance degradation, meeting the stringent reliability requirements of industrial and civil building fire protection systems. The vertical structure allows the pump shaft and motor shaft to be coaxial, resulting in high transmission efficiency, smooth operation, and effectively reduced mechanical losses and vibration levels, thereby extending the overall service life of the unit. The hydraulic components undergo precise calculations and repeated verification during the design phase. The impeller flow path is smooth and highly efficient, maintaining stable flow and pressure output within the rated operating range. This ensures uniform opening of sprinkler heads and stable network pressure even when multiple fire hydrant systems draw water simultaneously. The motor uses a dedicated motor with high starting torque and excellent overload capacity. It can quickly start and reach rated speed after a fire signal is triggered, shortening system response time and buying valuable time for initial fire suppression. The motor also features high insulation and good heat dissipation, suitable for long-term standby and high-load emergency operation of fire protection systems. In terms of performance matching, vertical electric fire pumps are typically selected based on actual project needs, ensuring the equipment operates near its design operating point. This avoids increased energy consumption or premature component wear due to prolonged deviations from optimal operating conditions, improving overall system efficiency and reliability. The complete set of equipment is generally equipped with a dedicated fire control cabinet, supporting automatic start, manual start, and remote linkage control. It can reliably link with fire alarm systems and pressure switches, ensuring accurate and timely operation even in unattended conditions. The selection of internal components for the control system prioritizes stability and anti-interference capabilities, featuring multiple protection functions including overload, phase loss, and short circuit protection, effectively reducing the risk of malfunctions while ensuring safe equipment operation. Pressure gauges, flow monitoring, and status indicators provide real-time feedback on system operation, facilitating daily inspections and maintenance by operations and maintenance personnel. The vertical electric fire pump boasts significant advantages in structural integration; the pump, motor, control cabinet, and piping components can be centrally mounted on an integrated base, simplifying on-site installation, shortening the construction period, and helping to reduce project costs and commissioning difficulty. A rational piping layout and valve configuration make system maintenance and repair more convenient, and key components are easy to disassemble and replace, benefiting long-term operation and maintenance. Considering the diverse usage environments of industrial and civil buildings, the equipment has been optimized for rust prevention, corrosion resistance, and environmental adaptability. The surface coating exhibits excellent corrosion resistance, enabling it to adapt to humid, dusty, or temperature-varying pump room environments, ensuring reliable starting performance even during long-term standby. In summary, vertical electric fire pumps for industrial and civil buildings, with their compact vertical structure, efficient and stable hydraulic performance, rapid and reliable start-up capability, and comprehensive control and protection functions, provide a safe, continuous, and stable water supply guarantee for various fire protection systems. They are an important solution in modern building fire protection engineering that balances performance and space utilization.