How to Improve Fire Pump System Reliability and Safety through Proper Selection

Fire pump systems play a crucial role in fire protection. When selecting a system, it is essential to consider factors such as building size, flow requirements, head pressure, and power source to ensure stable water supply in emergencies. Properly matching the pump model not only prevents overload or mismatches but also extends the equipment’s service life. Additionally, focus on product quality, manufacturer credentials, and compliance with national and international standards. Regular maintenance and inspections after installation further enhance the system’s overall safety and reliability.

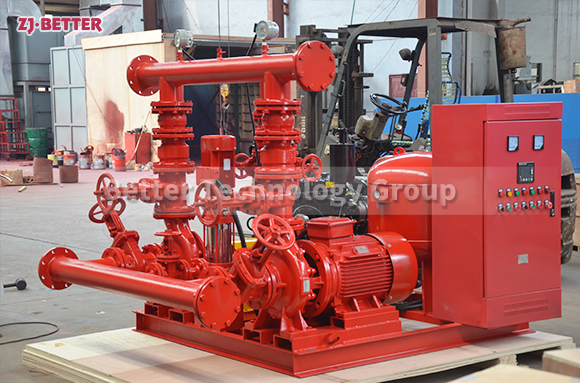

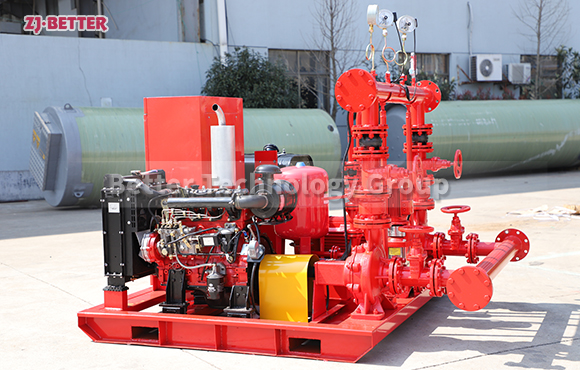

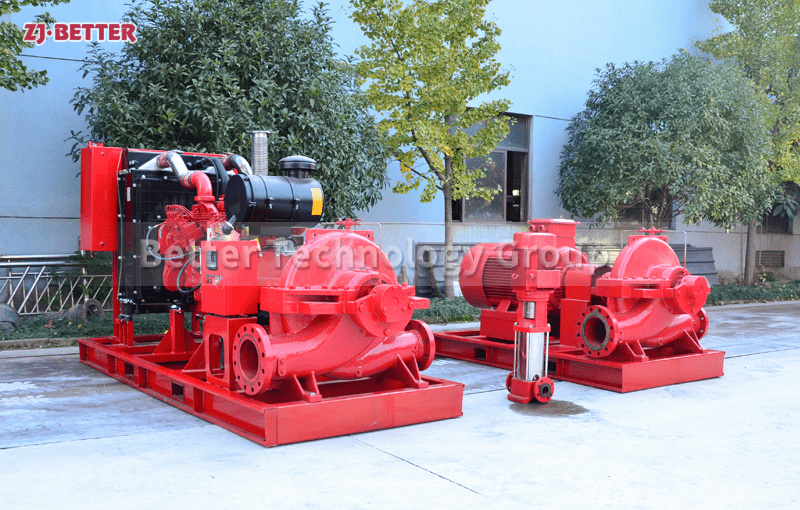

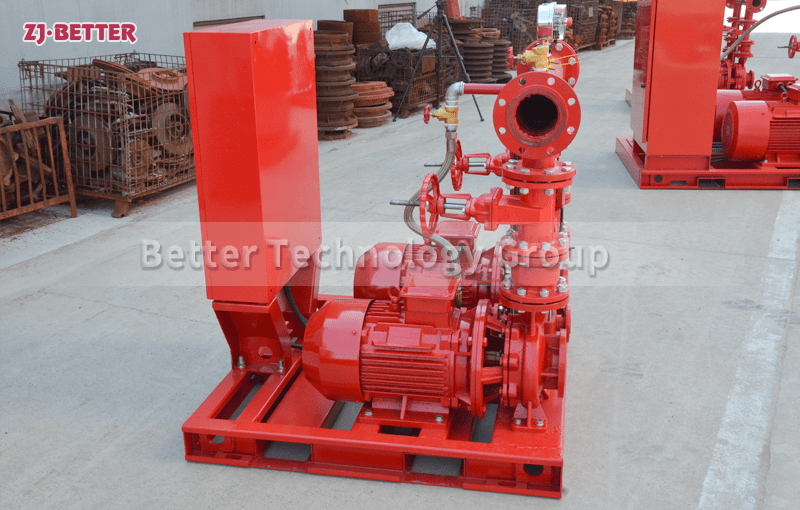

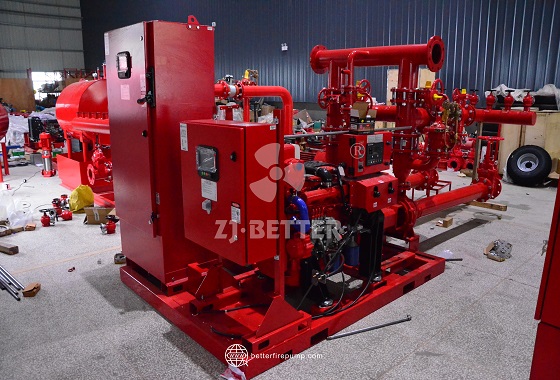

This enterprise specializes in the research, development, and manufacturing of fire pumps and fire water supply systems, offering electric fire pumps, diesel engine fire pumps, and integrated fire pump units. These products are widely used in high-rise buildings, industrial parks, logistics centers, and public facilities. All items strictly comply with relevant fire safety standards and undergo advanced processes and rigorous testing to ensure efficient and stable water supply performance. The enterprise values innovation and quality, providing customized firefighting solutions for various environments and earning customer trust through reliable after-sales support, with the goal of creating a safer fire protection landscape.

.jpg)