How does this fire pump ensure high efficiency and energy savings?

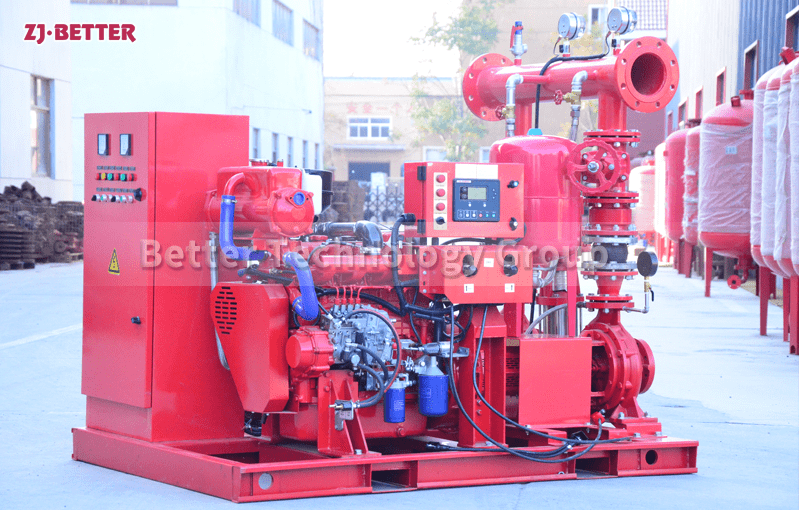

This fire pump features advanced hydraulic design and high-efficiency motor technology to maximize energy utilization. Its optimized impeller and flow passage structure reduce energy loss, improving hydraulic efficiency while lowering unit energy consumption. The intelligent control system automatically adjusts operating conditions based on demand, preventing unnecessary energy waste while ensuring stable and reliable water supply performance. Additionally, the low-noise and low-vibration design minimizes operating costs and extends service life. With its high efficiency and energy-saving advantages, this pump is an ideal choice for various fire protection systems, providing stable and reliable water supply when it matters most.

Our company specializes in the research, development, production, and sales of fire pumps and related equipment, committed to providing global customers with efficient and reliable fire water supply solutions. With advanced manufacturing processes and a strict quality management system, we ensure that every fire pump meets international standards.

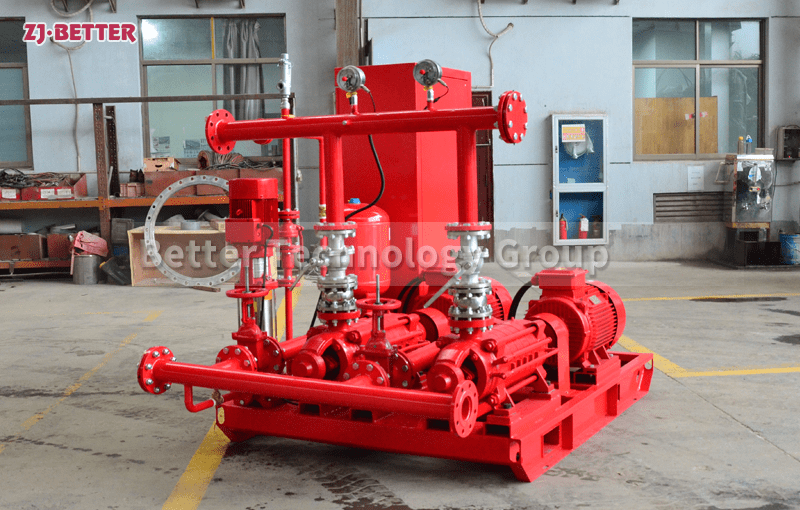

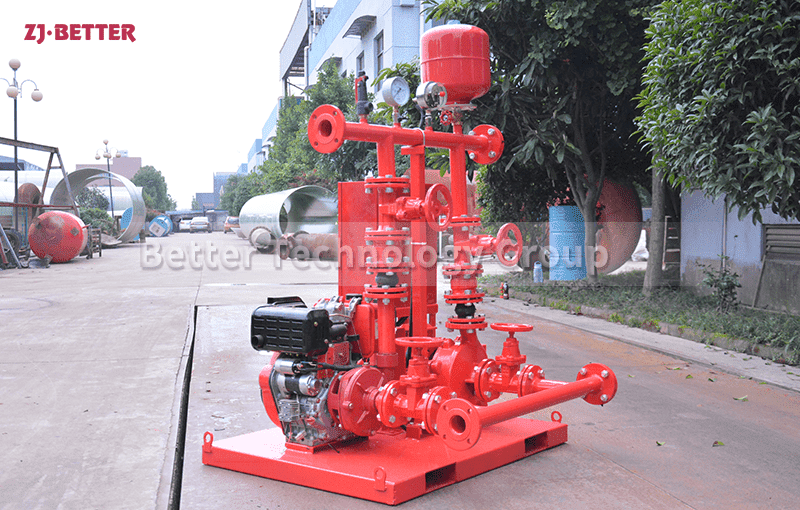

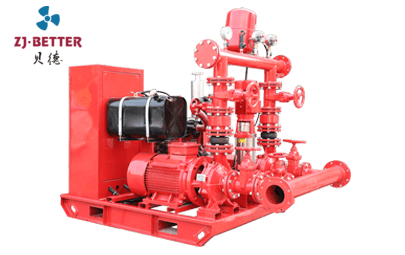

Our main products include electric fire pumps, diesel engine fire pumps, pressure stabilization equipment, and complete fire pump sets, widely used in buildings, municipal projects, industries, and petrochemical fields. These products feature high-efficiency energy-saving designs, offering high head, large flow capacity, low noise, and intelligent control, ensuring stable water supply in emergencies.

With extensive industry experience and strong technical support, we continuously innovate and optimize product performance to meet various fire protection needs. Upholding the philosophy of “Quality First, Customer Foremost,” we provide high-quality products and comprehensive services to ensure fire safety worldwide.