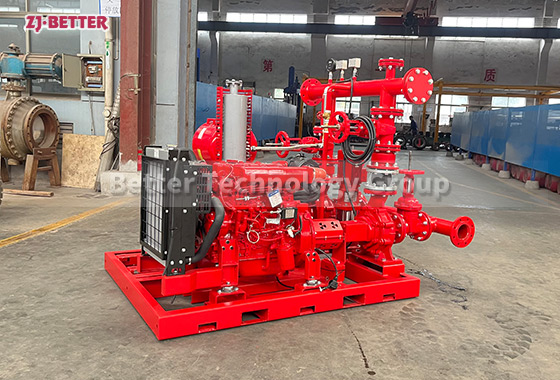

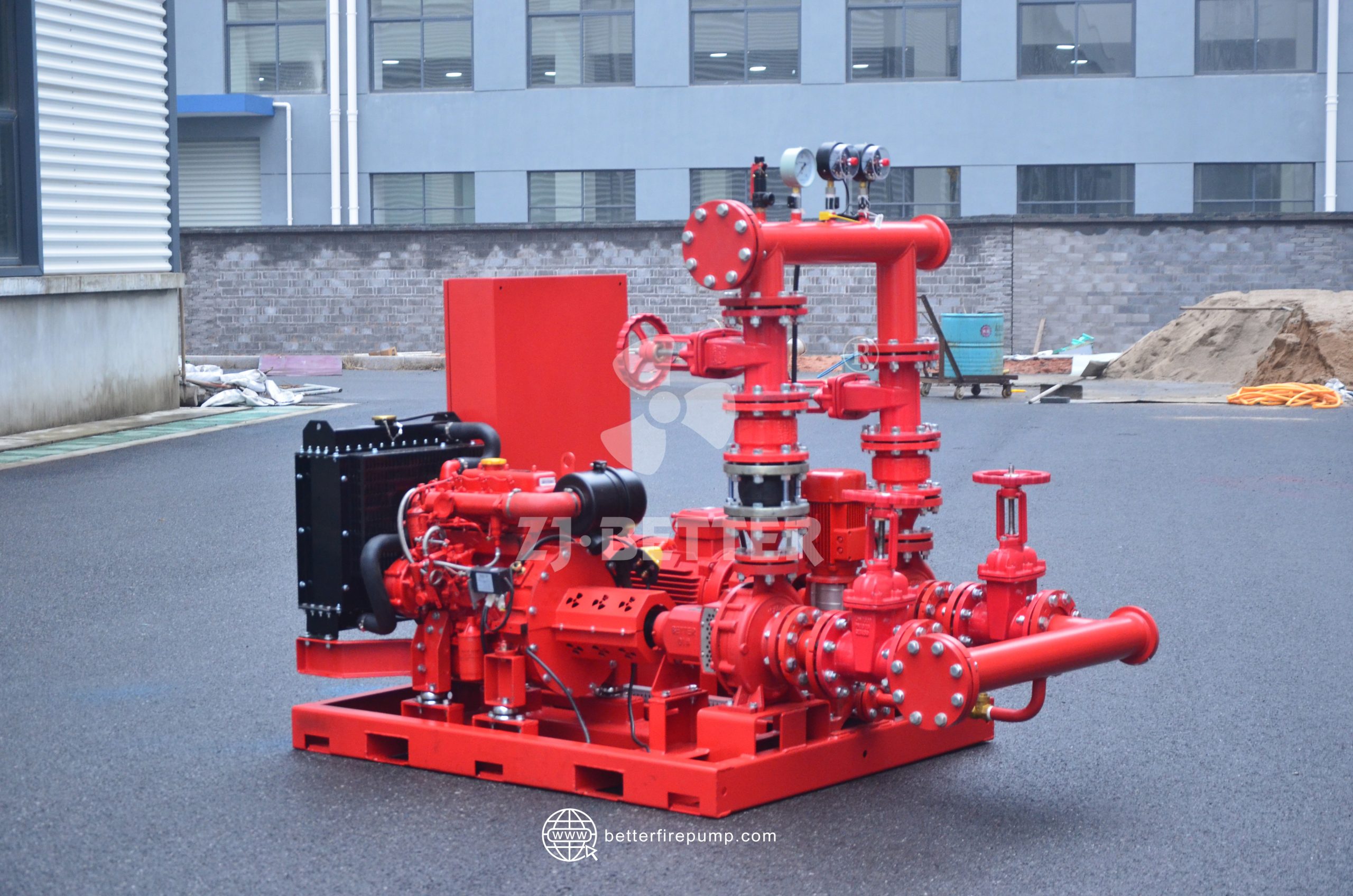

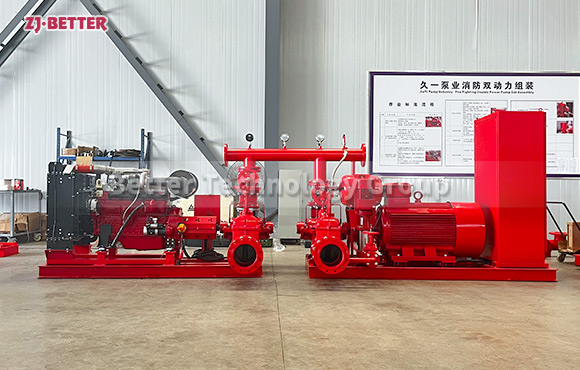

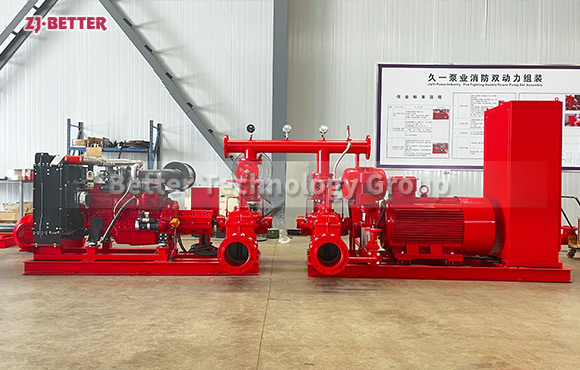

DJ Diesel Fire Pump

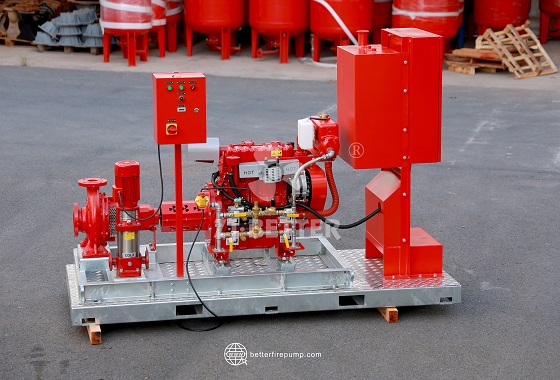

XBC diesel engine fire pump set is the latest according to the national standard GB6245-2006 “fire pump performance requirements and test methods”. This series of products has a wide range of lift and flow, and can fully meet the fire water supply in various occasions such as warehouses, docks, airports, petrochemicals, power plants, liquefied gas stations, textiles and other industrial and mining enterprises.

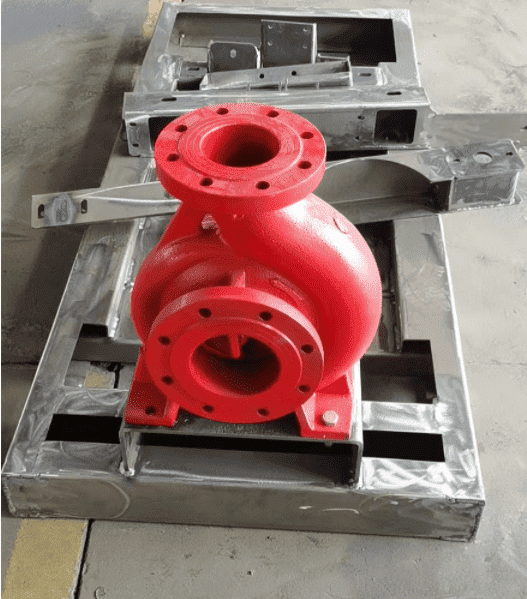

1. Diesel engine pump, can use single stage pump, horizontal split case pump, end suction pump, multistage pump, material can be cast iron, stainless steel, and bronze impeller , with fuel tank, water tank£¬fan, control box

4. Jockey pump, horizontal or vecal, capacity will be small, but head should be higher than electric and diesel engine pump

Jockey material casing :cast iron ,shaft and impeller SS304

3. Control panel: Auto Control of diesel engine pump and Jockey Pump with overload, over current protection

4. Accessories: check valve, gate valve, pressure vessel, generally 0.6mpa, 1.0mpa, 1.6mpa, Pressure Gauge, Pressure Sensor, Common Pipe for Suction and Discharge, Flexible Joints and Flanges, Common Base plant