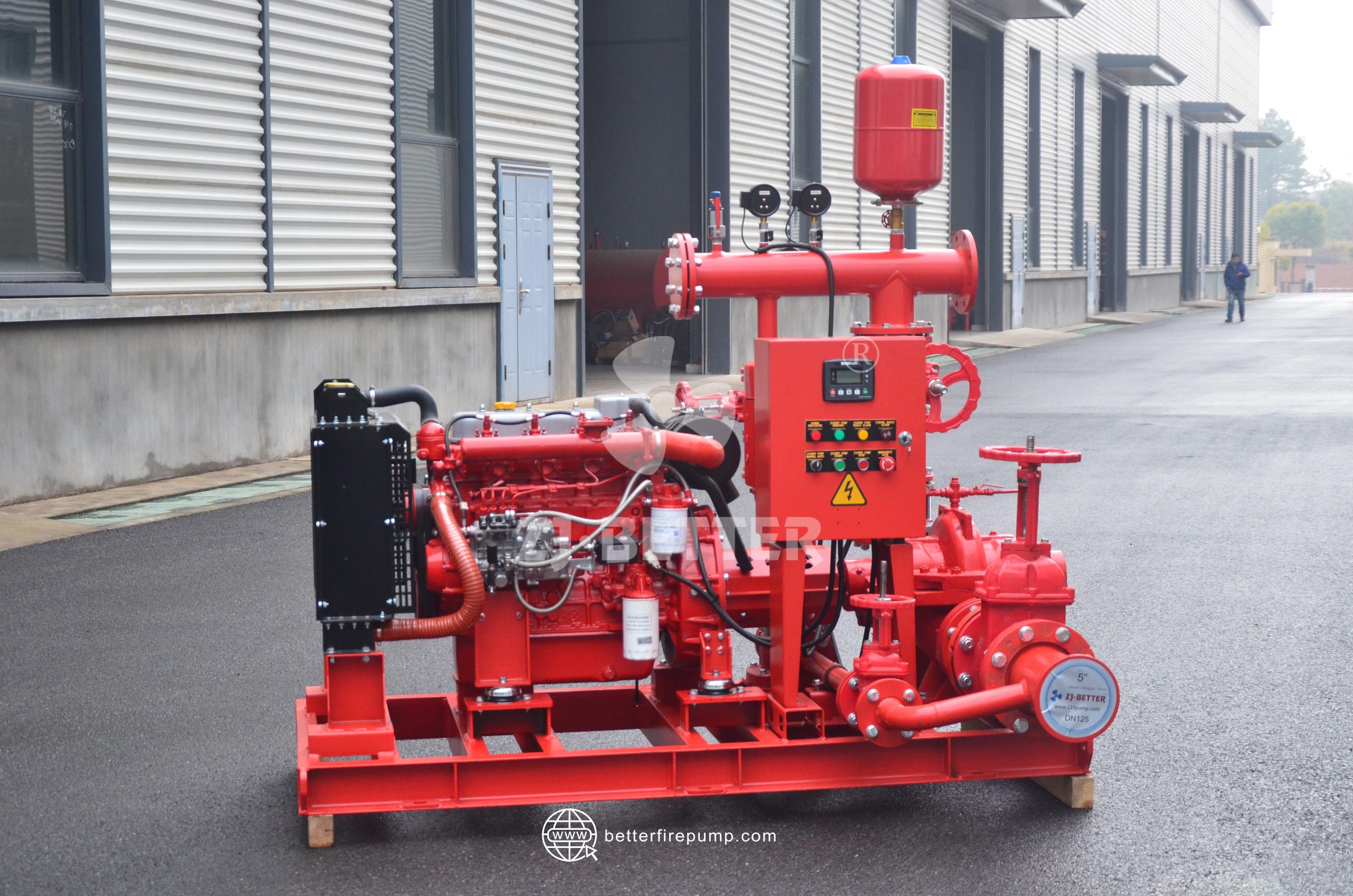

Fully Automatic Fire Pressure Maintenance System: Intelligent Monitoring and Multi-Stage Pressure Control

The fully automatic fire-fighting pressure stabilization system provides intelligent monitoring, multi-stage pressure regulation, and high-efficiency pressure stabilization performance, ensuring that the fire-fighting pipeline network maintains the best pressure state for a long time, improving the start-up speed of fire pumps and system reliability. It is suitable for various scenarios such as commercial buildings, factories, and high-rise buildings, and is an ideal choice for improving fire safety and operational stability.

As a core auxiliary device in modern building fire protection facilities, the fully automatic fire-fighting pressure stabilization system does not simply maintain pipeline pressure. Instead, it provides pre-emptive protection for the entire fire pump unit through precise and stable output, real-time intelligent monitoring, and multi-stage pressure regulation, enabling immediate activation in emergencies and truly achieving the safety goal of “fire protection system always on standby.” With the continuous development of urban buildings towards larger and more integrated structures, fire water systems are placing increasingly higher demands on stability, response speed, and automation. The fully automatic fire-fighting pressure stabilization system emerged and continues to evolve in response to these needs. This pressure stabilization device is applicable to various scenarios such as commercial complexes, factory workshops, logistics and warehousing bases, high-rise residential buildings, hospitals, schools, and underground projects. It can also perform graded pressure regulation according to different fire pipeline network sizes, making the system more precisely adapted to the actual needs of the project, thereby achieving all-weather, uninterrupted pressure maintenance capabilities. The core advantages of the fully automatic fire-fighting pressure stabilization system are reflected in its high degree of automation, multi-stage pressure regulation, compact structure, stable performance, energy efficiency, and long-term reliable operation. As an independently operating pressure stabilizing unit, it ensures that the pipeline pressure remains within the set range through continuous low-flow pressure replenishment or intermittent start-up modes. When the pipeline pressure drops due to leakage, slight water usage at the end, or changes in ambient temperature, the low-flow pump automatically replenishes the pressure; when the pressure drop is significant, the high-flow pump or main pressure stabilizing pump automatically switches to operation, providing higher water supply capacity. The entire operation requires no manual intervention; the system maintains a highly stable state through the coordinated operation of pressure sensors, controllers, and intelligent modules. Furthermore, the fully automatic fire-fighting pressure stabilizing system can also achieve parameter visualization and remote monitoring through an integrated control panel, including information such as current pressure, number of starts, runtime, motor status, and fault alarms. This data is extremely valuable in project operation and maintenance. Multi-level pressure regulation is a major highlight of this system. Traditional pressure stabilizing equipment typically only has single-point pressure control, while modern pressure stabilizing systems can perform multi-level pressure regulation according to the pipeline pressure requirements of different building fire compartments and different floors, making pressure control more precise and preventing damage to pipes and valves due to excessive pressure, as well as preventing start-up delays due to insufficient pressure. With the continuous improvement of building fire safety standards, multi-stage pressure regulation has become a basic requirement for high-quality fire-fighting pressure stabilization systems. Through the combination of intelligent algorithms and high-precision sensors, these systems respond to pressure changes faster, have a wider adjustment range, and possess adaptive adjustment capabilities. The system’s structural design fully considers long-term operational stability. The overall pump body is typically made of high-strength cast iron, corrosion-resistant alloys, or wear-resistant materials, effectively handling complex water quality environments. The motor section utilizes efficient air-cooling design or a sealed protection structure to ensure good heat dissipation under high load and long-term operation. To enhance the overall system’s sealing and durability, mechanical seals are often made of high-grade alloy materials, ensuring stability and eliminating leakage risks under high-pressure conditions. The control cabinet features a waterproof and dustproof design, enabling stable operation in humid, dusty, or high-temperature machine room environments, ensuring long-term reliable operation of the electrical control system. To further enhance the equipment’s safety and controllability, the fully automatic fire-fighting pressure stabilization system is also equipped with multiple protection functions, including phase loss protection, short circuit protection, overload protection, overvoltage and undervoltage protection, motor over-temperature alarm, liquid level monitoring alarm, and pressure anomaly alarm. In the event of any anomaly, the system automatically switches to safety mode and issues an alarm signal to ensure that pipeline pressure is not interrupted due to equipment failure and to provide maintenance personnel with accurate fault information for timely handling. One of the most prominent values of this type of system is its significant energy-saving effect. The combination of high-efficiency pressure-stabilizing pumps, low-flow pumps, and intelligent pressure regulation logic results in extremely low power consumption during normal pressure stabilization, requiring only minimal electricity to maintain pressure stability, while high-flow pumps typically only start when pressure drops rapidly or under abnormal system conditions. By using scientific algorithms to calculate start-up frequency and running time, the system avoids the energy waste and mechanical wear caused by frequent start-stop cycles of traditional pressure-stabilizing pumps, significantly extending equipment lifespan and improving economy and operational efficiency. The application value of fully automatic fire-fighting pressure-stabilizing systems is not only reflected in the equipment itself but also in the improvement of the entire fire-fighting system. For example, pressure stabilization systems effectively reduce the number of dry runs and the risk of accidental starts of the main fire pump, extending its service life and improving the availability of the fire protection system. A reasonable pressure maintenance state also ensures that various valves, sprinkler terminals, and alarm systems maintain good operating conditions. By maintaining stable pipeline pressure over a long period, problems such as pipeline corrosion, vibration, or pressure fluctuations caused by air entering the system can be avoided, thereby extending the overall lifespan of the pipeline network. Furthermore, fully automatic pressure stabilization systems support multiple installation methods, including foundation-based, integrated sliding, and modular structures that can be customized according to project needs, making them suitable for new construction projects, renovation projects, and confined machine room environments. Their compact structure and simple maintenance require only periodic checks of pressure sensors, motor lubrication, mechanical seals, and control cabinet operation, eliminating the need for complex operations and significantly reducing operating costs. Modern intelligent pressure stabilization systems can also achieve remote monitoring via IoT modules, linking with fire pump room management systems or building fire protection system mainframes to achieve multi-point data collection and centralized management. Management personnel can view pressure data, alarm information, and operating status in real time via computer or mobile devices, achieving a more efficient operation and maintenance management mode. For large industrial parks, industrial plants, and multi-building projects, remote monitoring significantly improves safety monitoring efficiency, enables unified management, and reduces manual inspection costs. The reliability of the fully automatic fire-fighting pressure stabilization system stems from its excellent redundancy design. The system configuration typically includes two or more pressure-stabilizing pumps: one as the main pump and one as a standby pump. When the main pump fails or requires maintenance, the standby pump automatically starts operating, ensuring uninterrupted pressure stabilization. This design effectively avoids pressure instability caused by a single device failure, keeping the fire protection system always in a state of safety readiness. For high-safety-level buildings, such as airports, hospitals, large commercial complexes, and chemical plants, stable redundant pressure stabilization capabilities are particularly important. The fully automatic fire-fighting pressure stabilization system also achieves a higher level of intelligent performance optimization. The system internally employs a high-precision sensor array, a fast data acquisition module, and an intelligent algorithm control board, enabling it to monitor pressure changes and respond at millisecond speeds, effectively avoiding risks such as sudden pressure drops and overpressure surges. Furthermore, the system supports a self-test mode, automatically checking whether various parameters are normal before equipment startup and issuing early warnings when potential faults are detected, preventing disruption to normal system operation. With its high degree of automation, stable operation, precise regulation, and intelligent monitoring, the fully automatic fire-fighting pressure stabilization system has become an indispensable component of modern building fire protection systems. It not only improves the operational reliability of the entire fire pump system but also provides the necessary prerequisite for the rapid response of the main fire pump in actual fire emergencies, enabling the fire water supply system to instantly enter its optimal working state. As a future direction for intelligent buildings, the fully automatic fire-fighting pressure stabilization system will continue to be upgraded technologically, developing towards greater efficiency, intelligence, safety, and energy conservation, providing more comprehensive and reliable fire safety protection for various building facilities. Through continuous design optimization, improved material quality, and expanded intelligent monitoring functions, its application scope will become wider, playing an increasingly important role in the construction of global fire protection systems in the future.