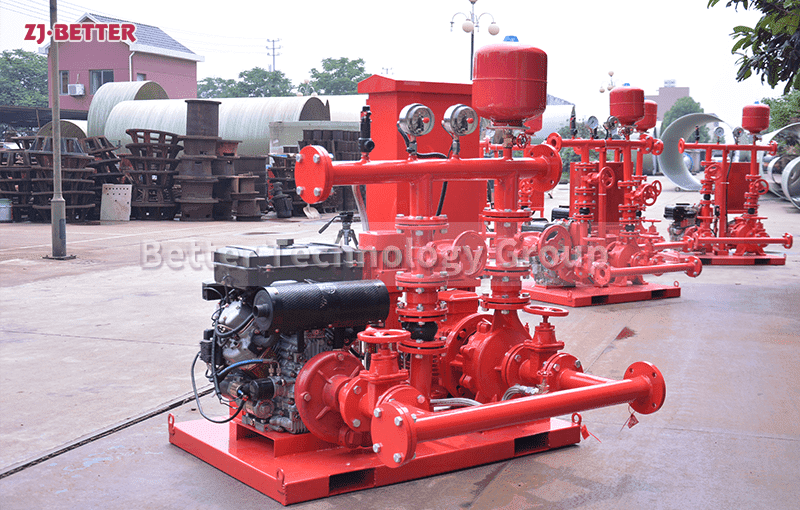

Performance and Application Value of Single-Stage Vertical Fire Pumps in Emergency Water Supply Systems

Discover the advantages and performance of single-stage vertical fire pumps in emergency water supply systems. Learn about their efficiency, reliable operation, and adaptability to various fire protection scenarios, making them a key component in modern firefighting infrastructure.

Single-stage vertical fire pumps are widely used in modern fire water supply systems. With their compact structure, stable operation, high efficiency, and convenient installation, they have gradually become core fire water supply equipment for high-rise buildings, industrial plants, municipal engineering projects, commercial complexes, warehousing and logistics, and various infrastructure projects, demonstrating irreplaceable performance value, especially in emergency water supply systems. This type of pump adopts a vertical structure design, placing the motor and pump body on the same centerline. This not only reduces the horizontal space occupied by the pump body but also effectively improves adaptability to the installation environment, making it particularly suitable for projects with limited machine room space and compact pipeline layouts. The single-stage design has a simple structure, reducing the complex wear points that may occur in multi-stage pumps, resulting in higher reliability and lower maintenance costs during long-term operation. Through optimized hydraulic structure, such as high-efficiency impellers, reasonable volute flow channels, and enhanced balancing mechanisms, the pump body maintains stable performance between output flow and head, enabling it to quickly output sufficient water and maintain stable pressure during a fire, providing a continuous and reliable water supply to the fire protection network. In emergency water supply systems, time and stability are the most critical indicators, and single-stage vertical fire pumps demonstrate significant advantages in both aspects. Their structural design allows for rapid start-up, typically reaching rated speed in a very short time, ensuring immediate response of fire water flow after fire-fighting facilities are activated. Simultaneously, the simple hydraulic channel and minimal fluid resistance allow the pump to maintain stable pressure even under high load conditions, without significant flow attenuation or pressure fluctuations, contributing to the overall high-efficiency fire-fighting capability of the entire fire protection system. During manufacturing, reinforced materials are commonly used, such as ductile iron pump bodies, copper alloy or stainless steel impellers, and high-hardness shaft seal structures, ensuring long-term durability when handling clean water, slightly corrosive water, neutral liquids, or fire-fighting water containing small amounts of impurities. The vertical layout allows direct connection between the pump shaft and motor, structurally reducing alignment difficulties and improving overall dynamic balance, resulting in less operating vibration and lower noise, making it suitable for building projects with strict noise requirements. Furthermore, because the motor is located above the pump body, it is less susceptible to the effects of humid environments even when installed near low-level water collection tanks, extending the equipment’s lifespan. Another outstanding value of single-stage vertical fire pumps in emergency water supply systems is their high adaptability and flexible application capabilities. From sprinkler systems and fire hydrant booster stations in high-rise buildings to pressurized water supply from industrial fire water storage tanks, and even rural fire stations and municipal emergency water supply points, they can meet the water supply needs under different working conditions. Their unique pipeline-type inlet and outlet structure allows the pump body to be directly connected in series with the pipeline system, greatly simplifying the installation process and maintenance difficulty. It also facilitates connection with automatic control systems, enabling functions such as pressure monitoring, automatic start/stop, and pipeline pressure compensation, meeting the intelligent needs of different scenarios. Many projects configure these pumps as pressure-stabilizing pumps; when the pipeline pressure drops to a set value, the pump automatically starts, ensuring that the fire pipeline network is always ready for firefighting. In large-scale projects, single-stage vertical fire pumps are also often used as main pumps, providing a large flow and highly stable water supply guarantee for the entire firefighting system during a fire. Thanks to its optimized hydraulic performance, this pump offers a wide range of applications in terms of high flow output and high head adjustment. By changing the impeller diameter or adjusting the speed, it can meet the fire water supply requirements of different building grades, making it suitable for both ordinary commercial facilities and industrial plants with high-strength fire protection regulations. The pump also boasts excellent energy efficiency. Through the use of a high-efficiency motor and optimized flow channel structure, it effectively reduces operating energy consumption and long-term operating costs. For fire protection systems requiring 24-hour standby, energy saving directly impacts project operating costs. The single-stage vertical fire pump, with its high-efficiency design, significantly increases water supply capacity per unit of energy consumption, especially in pressure-stabilized systems with continuous operation or frequent start-stop cycles. Furthermore, the equipment’s durability and reliability in emergency situations are invaluable. The pump body is robust, suitable for long-term high-speed operation; the mechanical seal uses high-temperature and wear-resistant materials to ensure no leakage in high-temperature environments or during continuous operation; the bearing system uses a long-life, wear-resistant structure, ensuring smooth operation even at high speeds and pressures. These design features ensure that mechanical failures will not affect the water supply capacity of the fire protection system during critical moments, thus guaranteeing overall fire extinguishing efficiency. Modern emergency water supply systems increasingly emphasize intelligent control, and single-stage vertical fire pumps possess excellent electrical control adaptability, seamlessly integrating with frequency converters, fire control cabinets, and remote monitoring systems. This enables intelligent speed regulation, remote start/stop, fault diagnosis, and operational data monitoring, contributing to the digital management of fire protection systems and improving safety monitoring capabilities. In practical applications, this pump can serve not only as a high-flow main pump but also as a backup pump, automatically switching operation when the main pump fails or lacks sufficient pressure, ensuring the fire protection system remains in a safe state at all times. Maintenance is simple, requiring only periodic checks of shaft seals, motor, bearing lubrication, and the wear of hydraulic components, greatly reducing the workload of equipment management personnel. Overall, single-stage vertical fire pumps, with their high hydraulic performance, excellent structural stability, convenient installation, reliable long-term operation, and high adaptability to various engineering scenarios, have become indispensable key equipment in modern emergency water supply systems. Whether in emergency firefighting, daily pressure stabilization, fire-fighting pressurization, or industrial water storage and pressurization, and municipal temporary water supply, it has demonstrated outstanding performance. As modern buildings increasingly demand higher safety standards for fire protection systems, this pump, with its continuous stability, high efficiency, energy saving, and ease of operation, will continue to play an irreplaceable and vital role in future fire protection projects, providing safe, reliable, and continuous fire-fighting water supply for various projects.