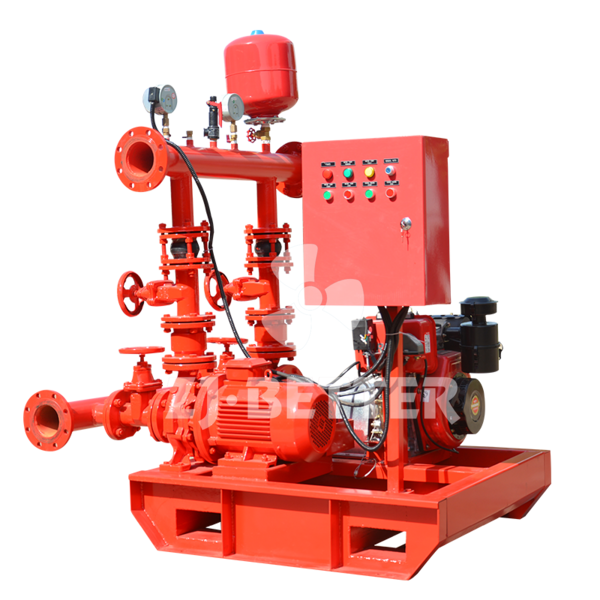

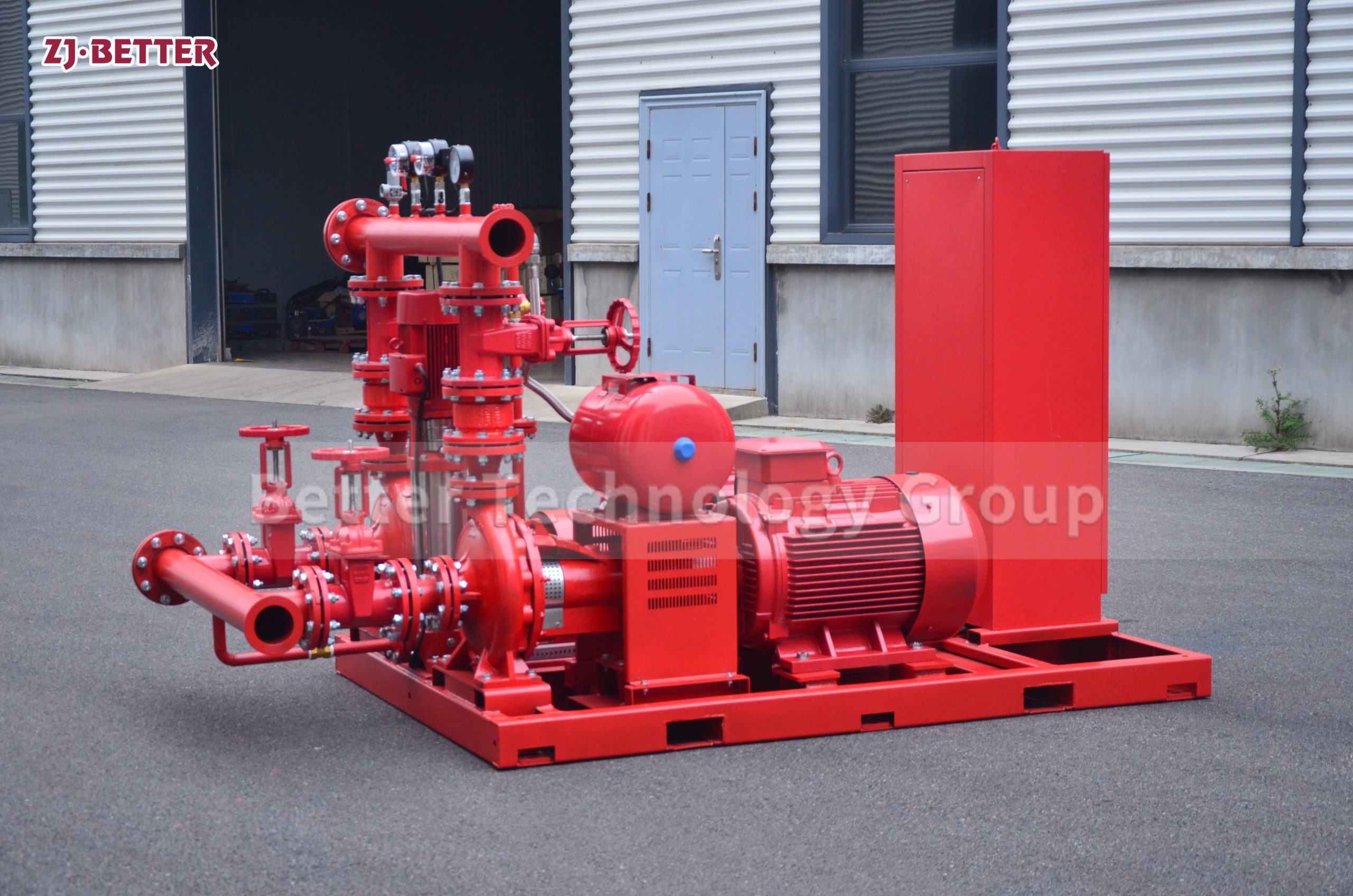

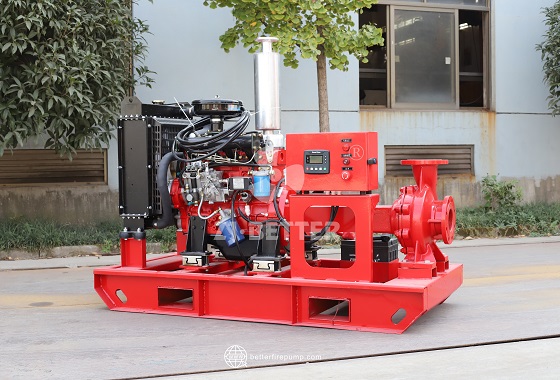

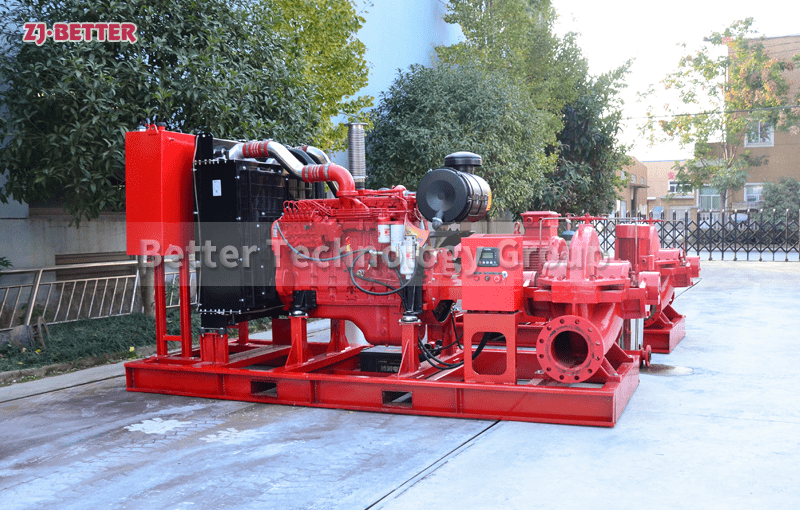

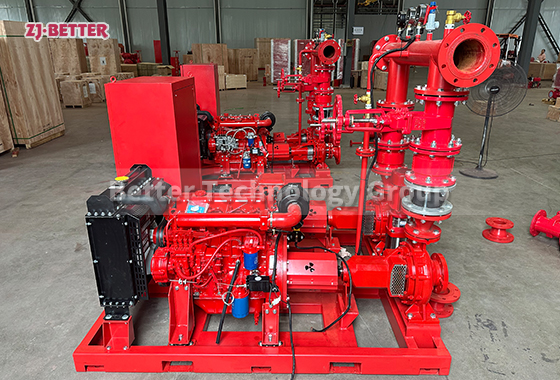

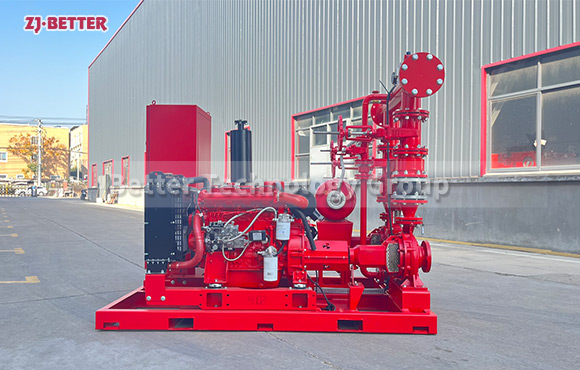

Horizontal EJ pump set

1. Electric fire pump: various end suction pumps and split pumps.

2. jockey pump: vertical, small flow, higher lift than electric or diesel pumps.

3. Control panel: Automatically control the water pump with overload and overcurrent protection.

4. Accessories: suction pipe, discharge pipe with flange, battery, gate valve, check valve, flexible expansion joint, pressure switch, pressure gauge, base, etc

The electric pump can make all kinds of end suction pump, split pump, single-stage pump, multi-stage pump; the pump casing is made of cast iron or stainless steel, and the impeller can be copper.

The technical parameters of the jockey pump are different from those of the electric or diesel pump and can be customized. It is usually small flow and has a higher head than an electric or diesel pump.

The Fire Pump Control Panel is the brain of the pump system and is designed to control and monitor the operation of the pump, electric, diesel and jockey pump drives, and compose the pump for manual and automatic models, as well as switch the pump drive on/off under specific conditions.