Small Flow Fire Pump Set

The minimum fire rated pressure of ED small fire fighting package set water supply equipment is 3 bar and the minimum fire rated capacity is 25 GPM. ED small fire fighting package set water supply equipment includes at least two power or power source driven pumping units, pressure tanks, pipes, valves and accessories, measurement and control instruments, control cabinets, outdoor rain cover, etc.

Motor: Three-phase asynchronous squirrel-cage motor independently developed and manufactured by our company, which can be controlled in production time and greatly shorten the whole set production time.

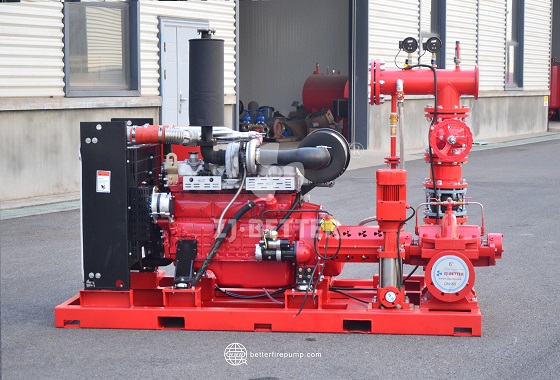

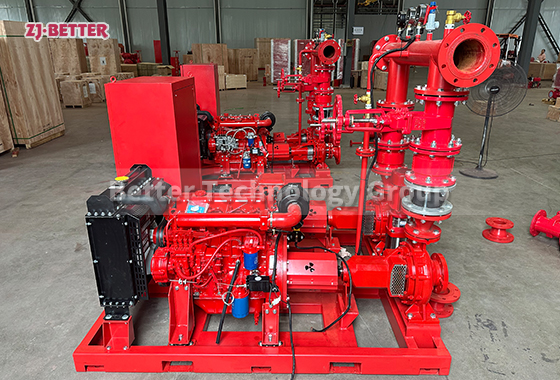

Diesel Engine: According to the different parameters of customers, we will choose diesel engines with high cost performance ratio. The main brands are QuanChai, Weichai, ShangChai, FAWDE, Cummins, etc.

Electric Pumps: Electric pumps can use vertical in-line pumps, horizontal end-suction pumps, vertical multi-

stage pumps, horizontal multi-stage pumps, split casing pumps and so on according to the different flow and head of customers.

Diesel Pumps: Diesel pumps can use vertical in-line pumps, horizontal end-suction pumps, vertical multi-

stage pumps, horizontal multi-stage pumps, split casing pumps and so on according to the different flow and head of customers.

Electronic Components: The main electric components is CHNT, if Schneider or other brand electrical are need, should mention it before place the order.

Safety Valve plays a safety protection role in the system. When the system pressure exceeds the prescribed value, the safety valve opens, and a part of the gas/fluid in the system is discharged into the atmosphere/pipeline, so that the system pressure does not exceed the allowable value, so as to ensure that the system does not cause accidents due to excessive pressure.

Pressure Tank: Water is a non-compressible medium. Generally speaking, the pressure drop of fire-fighting pipe network is normal. However, the pressure drop is very slow, the total loss of water in the pipe network isnot large, and the frequent change of pressure in the pipe network leads to frequent start-up and shutdown of pumps. Especially when the power of equipment is high, it will cause great impact on pressure sensors, relaysand motors, thus affecting the performance and life whole equipment. Therefore, it is necessary to choose the right volume of the pressure tank.

The minimum fire rated pressure of ED small fire fighting package set water supply equipment is 3 bar and the minimum fire rated capacity is 25 GPM. ED small fire fighting package set water supply equipment includes at least two power or power source driven pumping units, pressure tanks, pipes, valves and accessories, measurement and control instruments, control cabinets, outdoor rain cover, etc.

Motor: Three-phase asynchronous squirrel-cage motor independently developed and manufactured by our company, which can be controlled in production time and greatly shorten the whole set production time.

Diesel Engine: According to the different parameters of customers, we will choose diesel engines with high cost performance ratio. The main brands are QuanChai, Weichai, ShangChai, FAWDE, Cummins, etc.

Electric Pumps: Electric pumps can use vertical in-line pumps, horizontal end-suction pumps, vertical multi-

stage pumps, horizontal multi-stage pumps, split casing pumps and so on according to the different flow and head of customers.

Diesel Pumps: Diesel pumps can use vertical in-line pumps, horizontal end-suction pumps, vertical multi-

stage pumps, horizontal multi-stage pumps, split casing pumps and so on according to the different flow and head of customers.

Electronic Components: The main electric components is CHNT, if Schneider or other brand electrical are need, should mention it before place the order.

Safety Valve plays a safety protection role in the system. When the system pressure exceeds the prescribed value, the safety valve opens, and a part of the gas/fluid in the system is discharged into the atmosphere/pipeline, so that the system pressure does not exceed the allowable value, so as to ensure that the system does not cause accidents due to excessive pressure.

Pressure Tank: Water is a non-compressible medium. Generally speaking, the pressure drop of fire-fighting pipe network is normal. However, the pressure drop is very slow, the total loss of water in the pipe network isnot large, and the frequent change of pressure in the pipe network leads to frequent start-up and shutdown of pumps. Especially when the power of equipment is high, it will cause great impact on pressure sensors, relaysand motors, thus affecting the performance and life whole equipment. Therefore, it is necessary to choose the right volume of the pressure tank.