Electric Fire Pumps vs. Diesel Fire Pumps: Choosing the Right Fire Protection Solution for You

When selecting a fire pump, understanding the advantages and suitable scenarios for electric fire pumps and diesel engine fire pumps is essential. Each type of pump has its unique features, providing different fire protection solutions to meet varying needs.

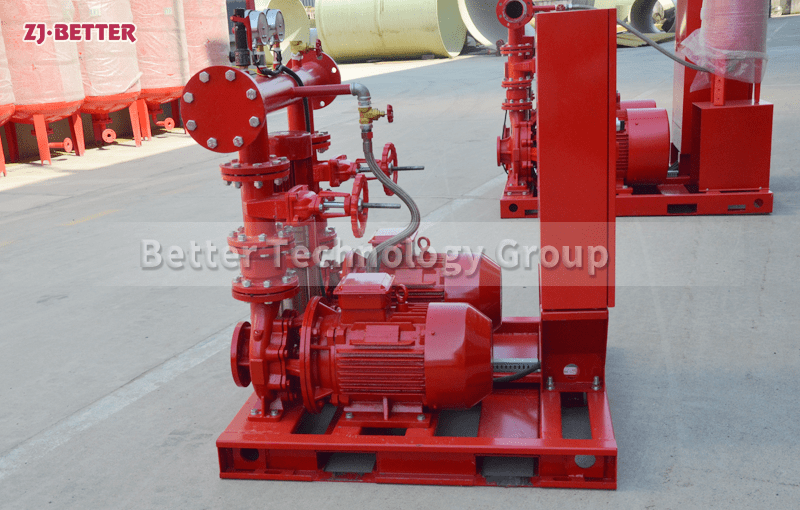

Electric fire pumps are ideal for environments with stable power supply. They typically have lower operational costs and higher efficiency. Electric pumps start quickly, produce less noise, and require less maintenance, making them the perfect choice for most modern buildings and commercial facilities. Their intelligent control system supports automatic start-stop, fault diagnosis, and remote monitoring, ensuring the system operates efficiently and safely.

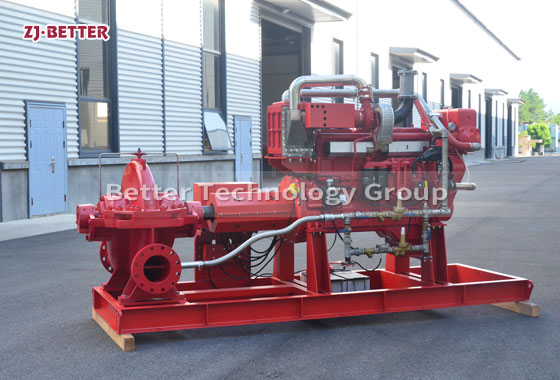

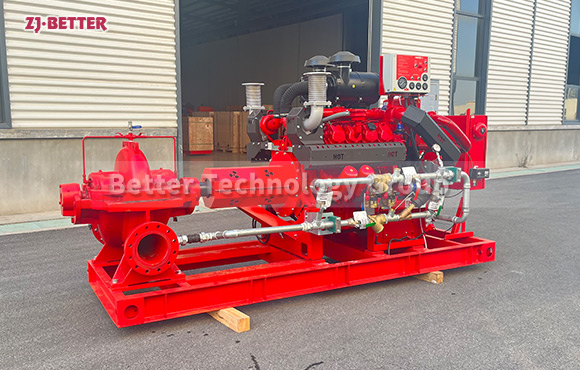

Diesel engine fire pumps, on the other hand, are better suited for locations with unstable or no power supply. Diesel pumps can operate independently in the absence of electricity, ensuring a stable water source during emergencies. Although diesel pumps are usually more expensive and require more maintenance, they have exceptional emergency capabilities and can operate reliably in any environment, making them particularly suited for industrial parks, mining areas, and remote regions.

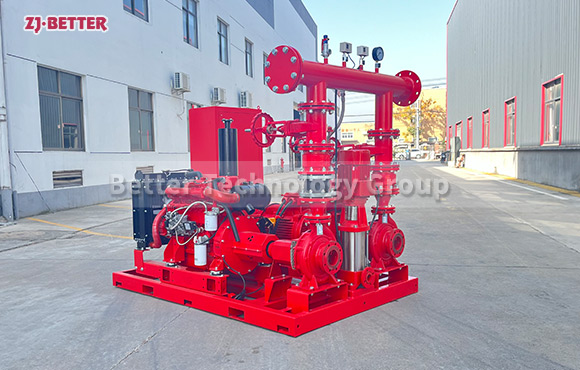

Choosing the right fire pump system should depend on the site’s power supply situation, operating costs, maintenance capabilities, and the required emergency response capacity. Whether opting for an electric fire pump or a diesel engine fire pump, we are committed to providing you with the most reliable and efficient fire protection solutions.

We are dedicated to providing top-quality fire pump equipment to ensure the fire safety of various buildings and facilities. Our product range includes electric fire pumps, diesel engine fire pumps, fire pump sets, and pressure-stabilizing water supply systems, widely used in industrial production, commercial buildings, residential areas, and municipal projects. Each product is carefully designed to operate reliably under extreme conditions, such as high pressure and high temperatures.

We use high-quality, corrosion-resistant materials to ensure our fire pumps perform excellently even in harsh environments. All of our equipment complies with international fire safety standards and is equipped with intelligent control systems that enable automatic startup, remote monitoring, and real-time alerts, significantly enhancing system efficiency and safety. Whether in daily operations or emergency situations, our fire pumps provide powerful and stable water flow, ensuring rapid fire suppression.

We continue to innovate by combining the latest technologies with engineering applications to meet the diverse needs of our clients, providing efficient, energy-saving, and reliable fire protection solutions for global users, safeguarding lives and property.