Fully Integrated from Tank to Pump: The Key Solution for Rapid Fire System Response

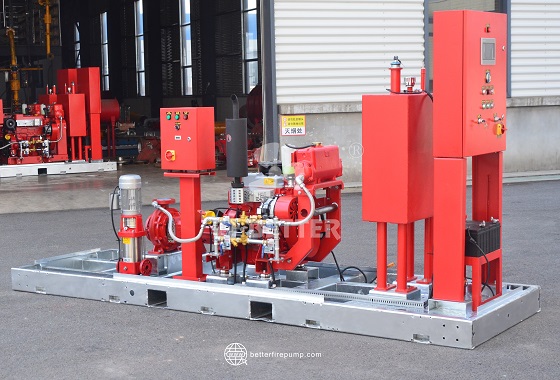

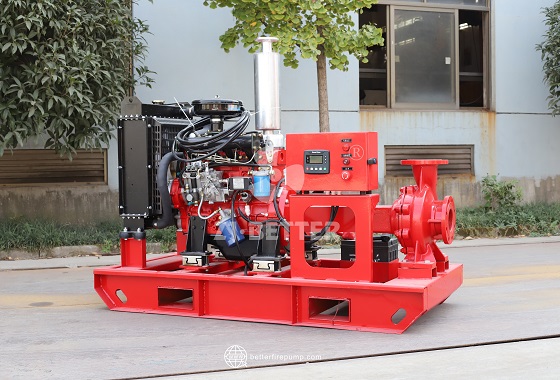

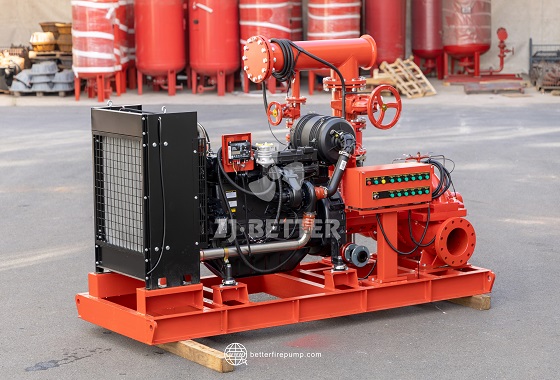

A fully integrated diesel fire pump system from fuel tank to pump body, designed for rapid emergency response—ideal for high-rise buildings, ports, and unattended fire protection scenarios.

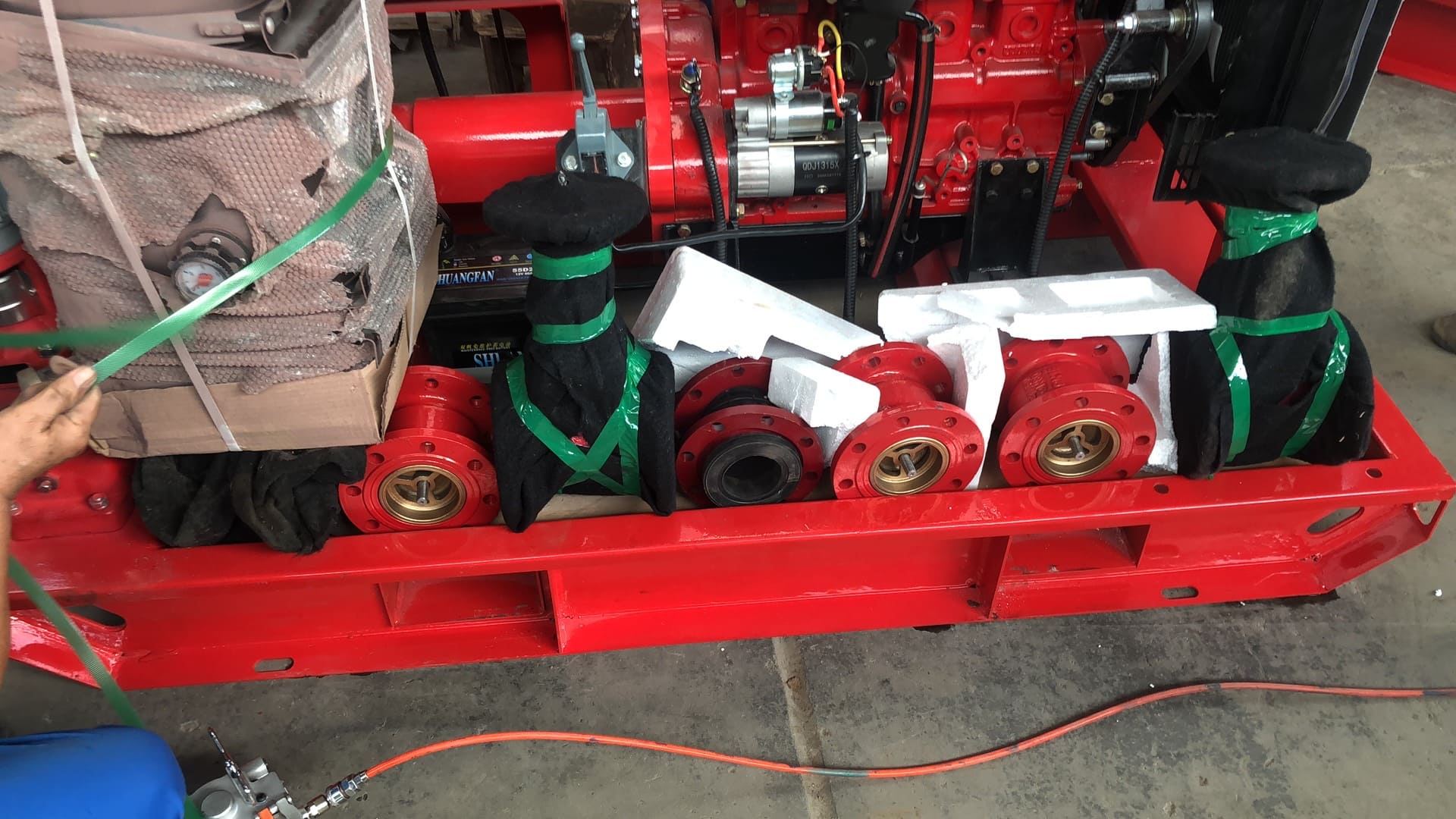

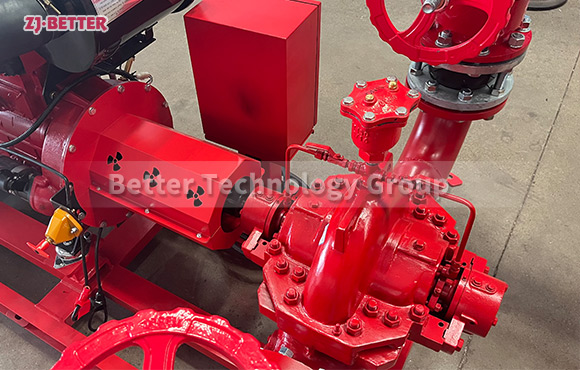

In modern building safety systems, the response speed and reliability of fire pump systems directly impact the effectiveness of fire suppression at the early stage. Particularly in emergencies, the level of equipment integration is crucial. Taking ZJ-BETTER’s integrated diesel engine fire pump system as an example, the comprehensive design—from the fuel tank to the pump body—greatly enhances quick startup, operational efficiency, and the system’s ability to function in power outages, high temperature, and humid environments. This system integrates the fuel tank, diesel engine, pump, control panel, pressure stabilizer, and cooling unit on a single base frame, significantly reducing connection losses and signal delays while achieving mechanical, electrical, and hydraulic synergy. For fuel management, the system includes a high-capacity, corrosion-resistant fuel tank with double-layered metal protection to prevent leakage and reduce evaporation. The tank connects to the diesel engine via a high-performance fuel pump and oil-resistant pipelines, ensuring stable delivery. The filtration accuracy reaches micron-level to prevent nozzle clogging and maintain power efficiency. The powertrain features a diesel engine sourced from leading international brands, delivering high torque, low vibration, and reduced emissions. Coupled with high-strength couplings and shock-absorbing mounts, it guarantees accurate power transfer and stable operation under heavy loads. The pump section adopts horizontal single-stage or multi-stage centrifugal pump structures, with housings made of ductile cast iron or stainless steel for high pressure and corrosion resistance. The dynamically balanced impeller ensures efficient and high-speed operation, enabling stable water delivery for various building applications. The platform also features an intelligent control cabinet equipped with automatic diesel engine startup, remote signal access, oil pressure and temperature alarms, and automatic inspection capabilities. Even in unattended environments, the system can self-check and switch modes based on pre-configured logic, enhancing autonomous functionality. Moreover, the control system supports integration with municipal water networks and central monitoring systems, enabling millisecond-level response upon fire alarm signal activation. The dual-loop cooling system combines forced air and water cooling, maintaining optimal engine temperature under fluctuating thermal loads, extending engine life and reducing maintenance frequency. For outdoor or extreme environments, the entire unit is protected by multi-layer anti-corrosion coating, with a galvanized steel base for durability, vibration resistance, and easy transport. Its compact layout makes it ideal for limited spaces such as underground pump rooms, high-rises, and port warehouses. In terms of maintenance, the modular design and quick-connect clamps on pipe joints allow for easy inspection and servicing even by non-specialists. Environmentally, the diesel engine meets Euro III or higher emission standards, supported by an efficient combustion system and exhaust purification unit, helping reduce CO and NOx emissions and aligning with green building goals. Overall, this fully integrated system—from fuel tank to pump body—not only shortens the fire pump response chain but also introduces breakthroughs in safety, automation, and operational continuity. It represents the evolution of fire pump units from standalone functions to intelligent integrated platforms. Especially in scenarios such as earthquakes, power failures, remote firefighting, and unmanned facilities, this integrated diesel fire pump station system offers a sustainable, highly reliable, and easy-to-manage solution. As smart cities and Industry 4.0 continue to develop, integrated fire protection systems like this will play an increasingly critical role in energy security, building protection, and high-end industrial applications.