Structural Design and Operating Performance of Motors for Fire Protection Systems

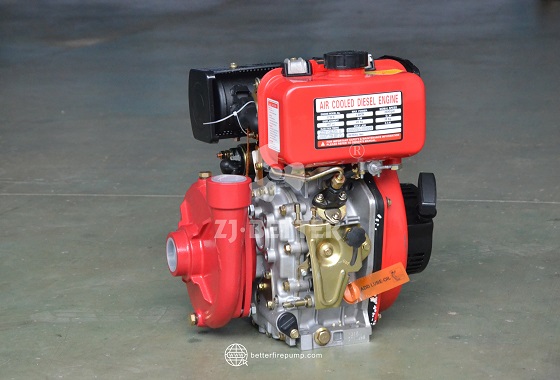

Fire protection system-specific motors have advantages such as robust structure, excellent heat dissipation performance, large starting torque, and long-term stable operation, providing reliable power for fire pumps and are suitable for various building and industrial fire water supply systems.

Motors specifically designed for fire protection systems are indispensable core components of fire-fighting water supply equipment. Their structural design and operational performance directly affect the stable and continuous operation of fire pumps in emergency situations, thus playing a crucial role in the overall fire protection system. Compared to ordinary industrial motors, motors specifically designed for fire protection systems emphasize reliability, durability, and stable output under extreme conditions. Their primary goal is not energy saving or frequent speed adjustments, but rather the ability to start unconditionally and maintain continuous operation during critical moments of a fire, providing stable power to the fire pump. These motors typically employ a reinforced structural design with high overall mechanical strength. Their internal windings, bearings, and insulation systems are optimized for fire protection conditions, ensuring good electrical performance and mechanical stability even under high loads, high temperatures, and prolonged operation. Structurally, motors specifically designed for fire protection systems often use enclosed or high-protection-level housing designs, effectively preventing dust, moisture, and other impurities from entering the motor. This makes them suitable for use in humid, high-temperature, or complex environments such as fire pump rooms, reducing the risk of failure due to environmental factors from the outset. The heat dissipation structure is a crucial component of the performance design of this type of motor. Through a rational layout of heat dissipation fins, optimized airflow design, and a matching cooling method, the motor can quickly dissipate internal heat during continuous high-load operation, preventing excessive temperature rise from adversely affecting the insulation system and winding life, thus meeting the stringent requirements of fire protection systems for long-term continuous operation. In terms of electrical performance, fire protection system-specific motors have a significant advantage in starting performance. They have sufficient starting torque, enabling the pump to quickly reach its rated speed upon startup. Even under high pipeline pressure or heavy load, they can start smoothly, avoiding delays in fire extinguishing due to starting failure. Simultaneously, these motors operate stably under rated conditions with minimal speed fluctuations, providing continuous and stable power output to the fire pump, ensuring that the outlet water pressure and flow rate remain within the design range. The reliability of the insulation system is one of the important indicators for evaluating the operating performance of fire protection motors. Motors specifically designed for fire protection systems typically use high-grade insulation materials and processes, possessing excellent heat resistance and anti-aging capabilities. Even in high-temperature environments or under prolonged energization, they maintain stable insulation performance, reducing the risk of breakdown and short circuits. The bearing system is also specifically designed, using high-temperature resistant and wear-resistant bearings, along with a reasonable lubrication method, to ensure the motor maintains low vibration and low noise during long-term operation, reducing the impact of mechanical wear on overall reliability. The special motor for fire protection systems also fully considers compatibility with fire pumps in its structural layout. The shaft extension type, installation dimensions, and power rating all meet the application requirements of fire pumps, ensuring efficient and stable transmission between the motor and pump body, reducing energy loss and operational hazards. In actual fire protection engineering, this type of motor typically serves as the power core of electric fire pumps, working in conjunction with the control system. Upon receiving a fire signal or pressure command, it quickly starts operating and maintains continuous power supply and stable output throughout the entire firefighting process. This “only success is allowed, failure is not permitted” operating characteristic is difficult for ordinary industrial motors to replace. For fire protection systems requiring long-term standby time, although the special motor’s daily operating time is not long, it must always be maintained in good condition. Therefore, its design focuses more on reliability under long-term storage and intermittent operation conditions, ensuring smooth restart after long-term shutdown. In terms of overall performance, motors specifically designed for fire protection systems provide a solid and reliable power guarantee for fire pump systems thanks to their reinforced structural design, excellent heat dissipation performance, stable electrical characteristics, and outstanding starting and continuous operation capabilities. They are an important basic equipment to ensure that fire water supply systems can play their due role in emergency situations, and have irreplaceable application value in various building fire protection, industrial fire protection, and infrastructure fire protection projects.