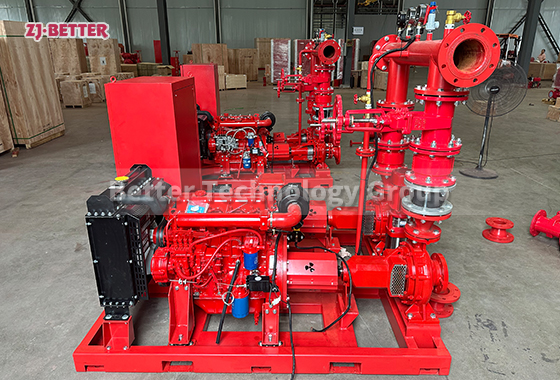

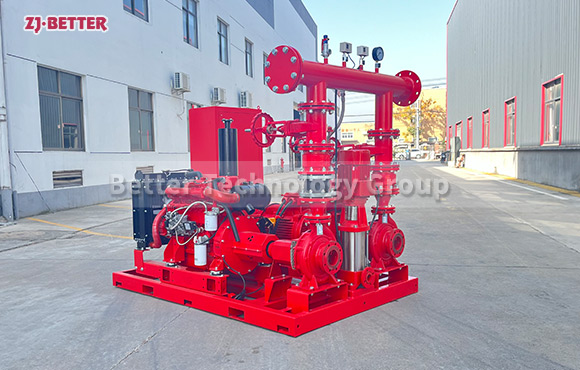

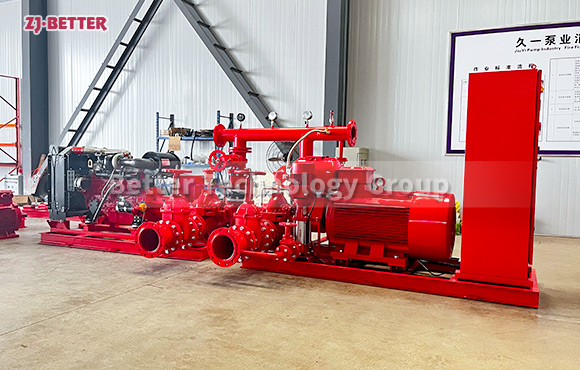

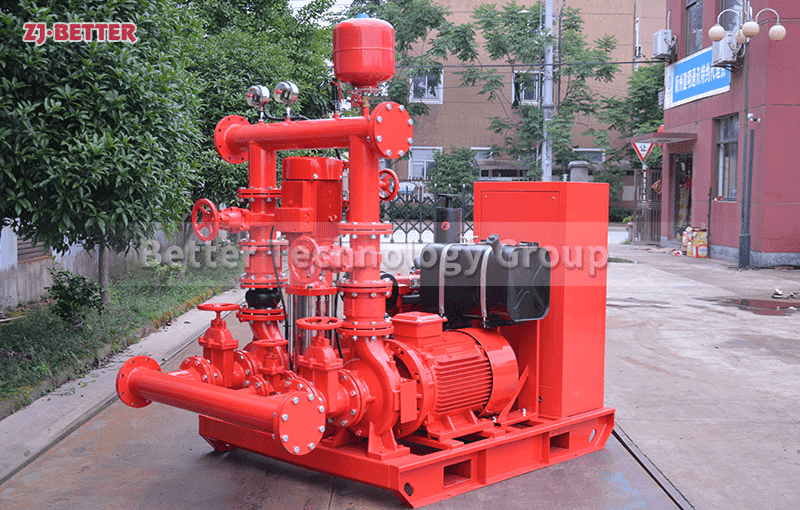

High Quality Diesel Engine Fire Pump Set

Diesel engine fire pump is a kind of mechatronics equipment that is directly driven by diesel engine fire pump and can start and complete water supply in a short time. Diesel engine pump set is driven by diesel oil without external power supply. Diesel engine pump is suitable for agricultural irrigation, emergency rescue, smelting, hangars, petrochemical oil depots, power plants, liquefied gas stations, textiles and other fire-fighting water supply occasions, especially in the absence of electricity, When the power grid is not satisfied, it is the safest choice to use a diesel engine to drive the water pump.

1. The diesel engine pump set is easy to use. It can be equipped with remote-transmitting instruments and meters, which can be connected to the control center as needed, and the installation and operation are convenient for maintenance and maintenance.

2. The diesel engine pump set has a high degree of automation, with automatic and manual and fault self-checking functions, monitoring the working conditions in the whole process, recovering from faulty starting failures, automatic restarting function, automatic pre-smoothing and pre-heating, making the equipment start more safe and reliable .

3. The diesel engine pump set has the functions of remote control and remote control in the central control room, and can also have field bus connection.