How Split Case Fire Pumps Ensure Continuous High-Flow Water Supply?

The horizontal split case fire pump offers high flow capacity, double-suction design, low noise, and easy maintenance—making it the ideal solution for stable fire protection in modern buildings, industrial zones, and municipal projects. Discover its structure, performance, and wide-ranging applications.

In modern fire protection systems, the ability to maintain a high flow rate of water supply is a critical factor in ensuring the efficiency of firefighting operations. As the core equipment in such systems, split-case fire pumps stand out due to their unique structural design and stable operational performance, making them the preferred choice for fire protection systems in various large-scale buildings, industrial parks, municipal projects, underground facilities, and other similar venues. Among various types of fire pumps, horizontal split-case fire pumps are highly favored by engineering designers and users due to their high efficiency, large flow rate, low noise, and ease of maintenance.

The most distinctive feature of split-case fire pumps is their “split-case structure,” where the pump body is horizontally split along the axis, allowing the rotor assembly to be directly removed from the middle of the pump body without disassembling the inlet/outlet pipes or motor. This design significantly reduces maintenance difficulty and costs, making it particularly suitable for large-scale applications requiring rapid restoration of operation, such as petrochemical plants, power stations, and high-rise building complexes. This structure allows horizontal split-case pumps to undergo routine maintenance and internal cleaning even after prolonged operation, ensuring the water supply system’s efficient response capability during critical moments.

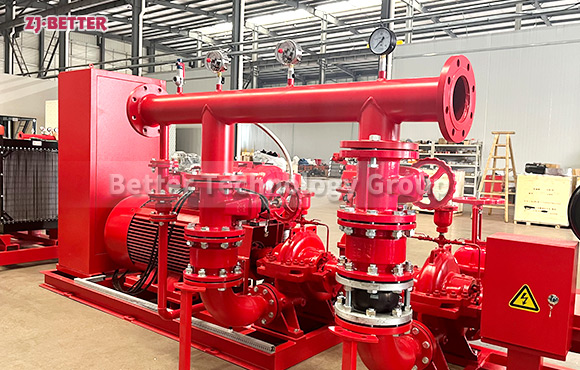

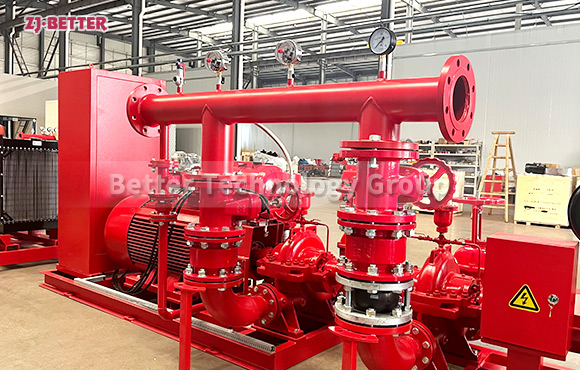

From a performance perspective, split-case fire pumps typically adopt a double-suction impeller design, effectively enhancing the pump’s suction capacity, reducing the impact of axial force, and improving operational stability. Its high-flow characteristics can easily handle complex firefighting demands requiring simultaneous water supply to large areas and multiple points, with a maximum flow rate of thousands of cubic meters per hour, far exceeding the water supply capacity of traditional single-stage centrifugal pumps. More importantly, its high-head design ensures sufficient pressure output even in complex terrains or high-rise buildings, guaranteeing uninterrupted water supply over long distances or across multiple levels.

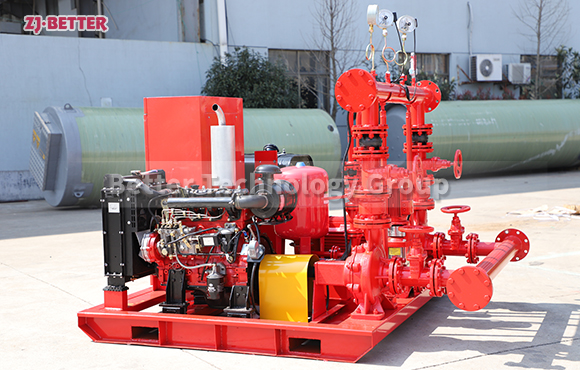

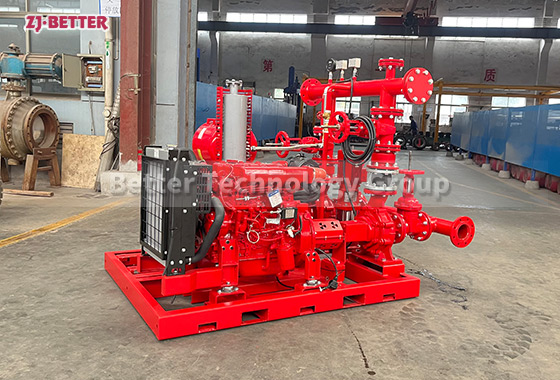

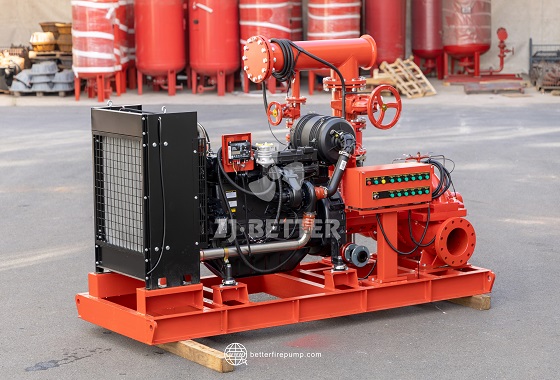

Split-case fire pumps are primarily constructed from cast iron or ductile iron, though stainless steel or other corrosion-resistant materials can be selected as needed to further enhance the equipment’s corrosion resistance and service life. In terms of structural compactness and layout rationality, this pump type can be integrated with diesel engines, electric motors, and control systems to form a fire pump unit, compatible with various fixed installations or emergency mobile devices, offering high engineering adaptability and flexibility. Its basic design complies with international fire safety standards such as GB6245, NFPA20, and EN12845, meeting standardized requirements across different countries and regions.

In terms of noise control, the horizontal split-case pump reduces vibration and noise during operation through optimized hydraulic modeling and flow path design, making it ideal for environments requiring quiet operation, such as hospitals, commercial buildings, and government offices. Additionally, this pump maintains high efficiency under both full and partial load conditions, effectively reducing energy consumption, making it a crucial component of energy-efficient fire protection systems.

Split-case fire pumps can be integrated with intelligent control systems during operation to achieve functions such as remote monitoring, automatic start/stop, water pressure feedback, and flow regulation, significantly enhancing the system’s response speed and automation level. Especially in fire scenarios requiring 24/7 standby, when used in conjunction with air-pressure water tanks, pipeline pressure sensors, and alarm systems, they can achieve true unmanned operation, reducing manpower requirements and improving operational reliability.

From an installation perspective, this pump type has relatively low foundation requirements, featuring an integrated base-mounted structure that can be directly installed on the ground. On-site assembly is simple, and commissioning takes minimal time. Additionally, its dual inlet design not only improves suction efficiency but also reduces cavitation risks, extending the pump’s operational lifespan. The dual-support bearing structure ensures even force distribution across the pump body, maintaining excellent dynamic balance even during prolonged high-load operation.

Split-case fire pumps are widely used in high-risk areas such as airports, subways, tunnels, oil depots, and port terminals, and are also suitable for various water supply modes such as rural water conservancy fire protection and internal network water supply in industrial zones. They are an indispensable component of modern fire protection systems. Whether used as a main pump or integrated into a complete system with pressure-stabilizing pumps and sprinkler pumps, the split-case pump demonstrates exceptional performance and engineering adaptability, ensuring reliable, efficient, and stable operation under complex conditions.

In summary, the split-case fire pump, with its scientific structure, stable operation, convenient maintenance, and superior performance, demonstrates significant application value in the context of growing demand for high-flow water supply in modern times. It is not only a core device for fire safety assurance but also a key driver for the development of intelligent fire protection systems toward efficiency, automation, and environmental sustainability. For any engineering project with stringent requirements for water supply efficiency and system stability, the horizontal split-case fire pump is undoubtedly the most reliable choice.