Choosing a good fire pump is crucial for ensuring the effectiveness and reliability of your fire protection system. Here are some key factors to consider when selecting a fire pump:

Flow and Pressure Requirements: Determine the required flow rate and pressure for your specific application. Consider factors such as the size of the protected area, the type of fire hazards, and any applicable fire safety regulations. Ensure that the fire pump you choose can meet these requirements.

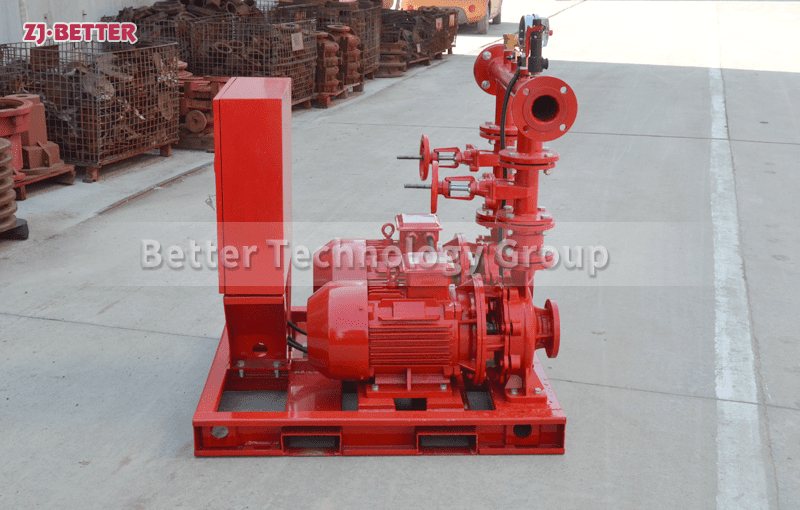

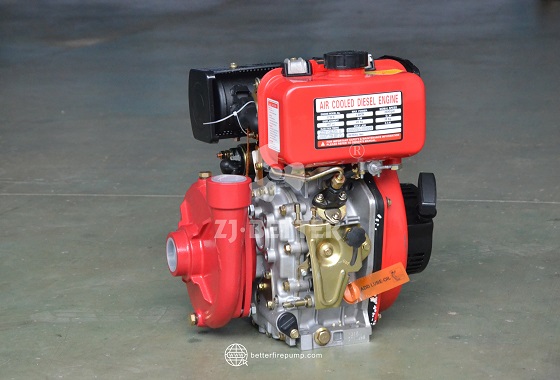

Pump Type: Select the appropriate pump type based on your needs. The two common types of fire pumps are centrifugal pumps and positive displacement pumps. Centrifugal pumps are widely used due to their high flow rates and ability to handle large volumes of water. Positive displacement pumps, on the other hand, are better suited for applications that require high pressure but lower flow rates.

Performance and Efficiency: Look for a fire pump that offers high performance and efficiency. Consider the pump’s rated capacity, which indicates the maximum flow rate it can deliver. Additionally, check the pump’s efficiency rating to ensure it operates optimally and minimizes energy consumption.

Reliability and Durability: A good fire pump should be reliable and durable to withstand the demands of fire protection operations. Consider the quality and reputation of the manufacturer, as well as the pump’s construction materials. Look for features such as corrosion-resistant coatings, sturdy construction, and reliable seals and bearings.

Compliance with Standards: Ensure that the fire pump you choose complies with relevant industry standards and codes, such as the National Fire Protection Association (NFPA) standards. Compliance with these standards ensures that the pump meets essential safety and performance requirements.

Maintenance and Support: Consider the ease of maintenance and availability of support for the chosen fire pump. Look for pumps with accessible components, clear maintenance instructions, and readily available spare parts. Additionally, check if the manufacturer or supplier provides technical support and assistance.

Testing and Certification: Check if the fire pump has undergone rigorous testing and certification by reputable organizations. Look for certifications from recognized bodies that validate the pump’s performance, efficiency, and safety.

Budget and Cost Considerations: While it is essential to choose a reliable and efficient fire pump, consider your budget and cost constraints. Compare prices, warranties, and ongoing maintenance costs to find a balance between quality and affordability.

System Integration: Consider how the fire pump will integrate with your overall fire protection system. Ensure compatibility with other components, such as fire alarms, sprinklers, and control panels. Coordinate with system designers or consultants to ensure seamless integration.

Consult with Experts: If you are unsure about the specific requirements or complexities of selecting a fire pump, consult with fire protection experts, engineers, or consultants. They can provide valuable insights and recommendations based on your unique needs and circumstances.

Remember that selecting a good fire pump is a critical decision that requires careful consideration. By evaluating the factors mentioned above and seeking professional guidance, you can choose a fire pump that meets your requirements and ensures the safety of your property and occupants in the event of a fire.