Guardian of High-Rise and Underground Projects: Advantages of Vertical Inline Fire Pumps

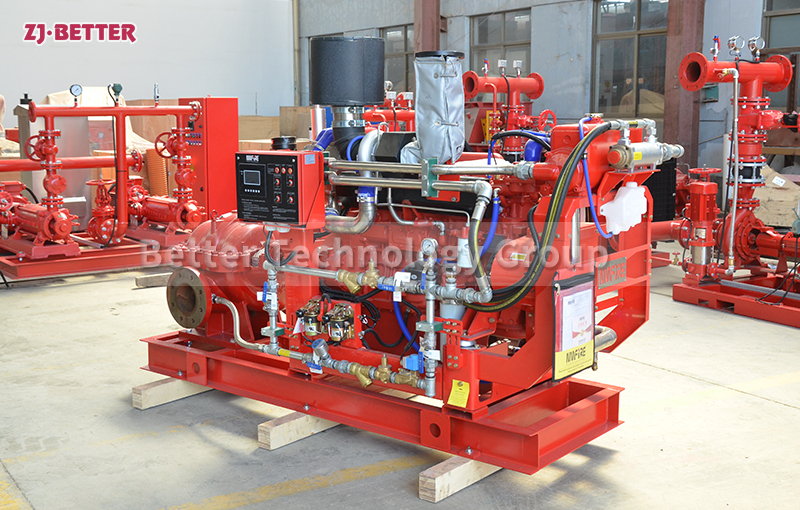

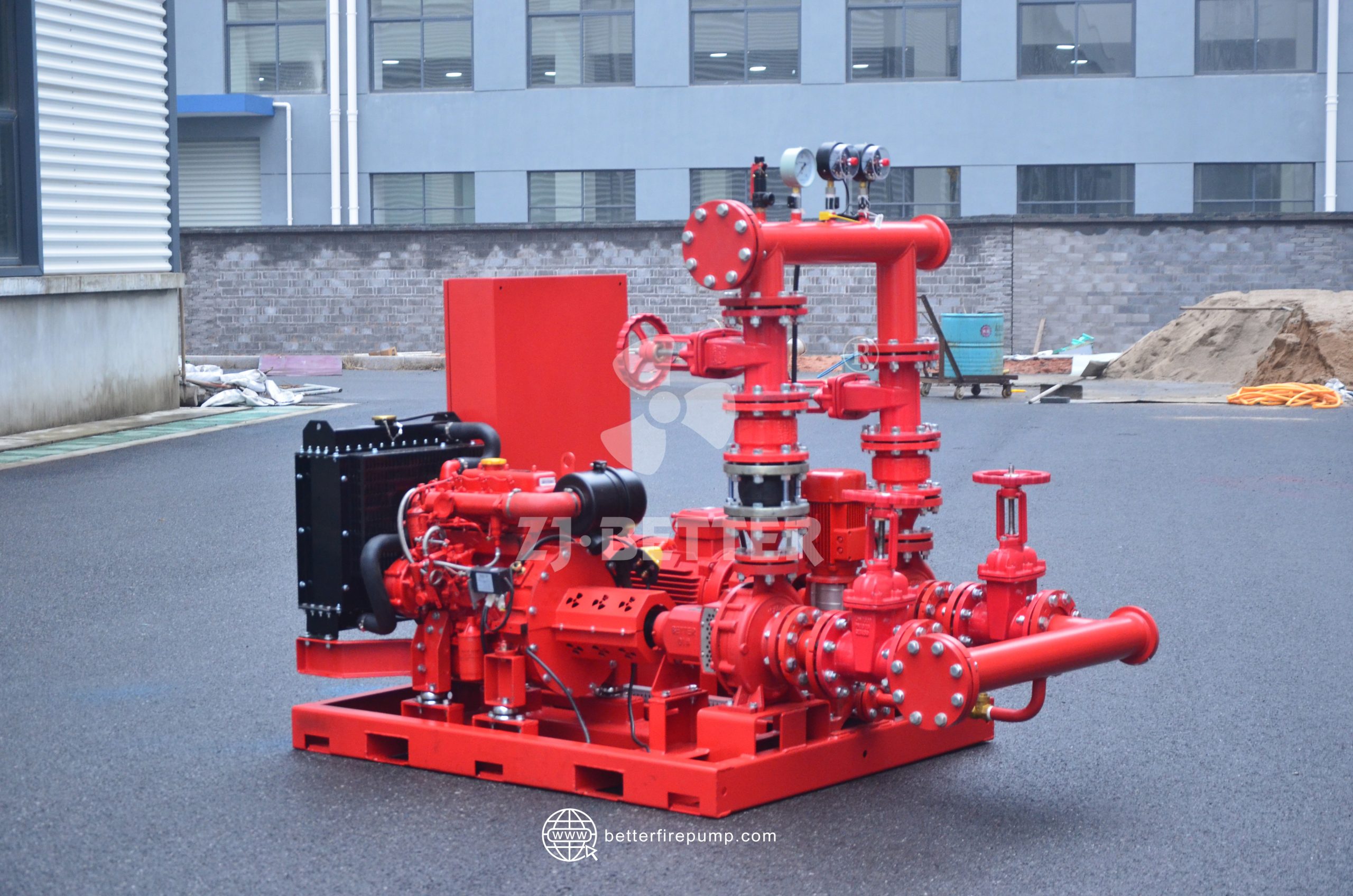

High-efficiency vertical in-line fire pumps offer stable water pressure, fast start-up, and high durability. They are compact and easy to install, making them suitable for high-rise buildings, factories, and large public facilities, ensuring reliable and safe fire emergency water supply.

With the increasing number of high-rise buildings and underground projects in modern urban construction, fire safety requirements are becoming increasingly complex and urgent. High-rise buildings, due to their height and high water pressure requirements, and underground projects, due to their limited space and complex environments, place far higher demands on fire pump equipment than ordinary buildings. Vertical in-line fire pumps, with their compact design, stable performance, and efficient water supply, are an ideal choice for these scenarios. They not only ensure the fire protection system’s immediate response in emergencies, but also maintain low energy consumption and a long lifespan during daily operation, ensuring continuous protection of building safety. One of the greatest advantages of vertical in-line fire pumps is their space-saving design. Compared to traditional horizontal pump units, the vertical design allows for efficient equipment placement within limited spaces, making it particularly suitable for basements, small machine rooms, and equipment space constraints in high-rise buildings. This design not only facilitates installation and maintenance, but also significantly reduces the machine room footprint, thereby saving building space costs. Furthermore, the vertical structure places the inlet and outlet on the same level, simplifying piping layout and reducing the complexity of construction and subsequent maintenance. Stable performance is another major advantage of vertical in-line fire pumps. This type of pump unit utilizes a high-performance motor drive and an optimized hydraulic model design, ensuring stable operation despite high head and flow demands, avoiding pressure fluctuations that could impact the firefighting system’s water supply reliability. Especially in high-rise buildings, vertical inline fire pumps can quickly build sufficient water pressure to ensure the simultaneous operation of sprinkler and fire hydrant systems, effectively addressing the initial stages of firefighting. Furthermore, vertical inline fire pumps demonstrate exceptional adaptability in underground environments such as subway stations, underground shopping malls, and parking garages. These locations often place stringent requirements on noise, vibration, and durability. With optimized dynamic balancing and low-noise operation technology, vertical pumps not only maintain long-term stable operation but also effectively reduce operating noise, enhancing overall comfort and environmental friendliness. High efficiency and energy conservation are key reasons for the widespread acceptance of vertical inline fire pumps. Their precision-engineered hydraulic channels minimize energy losses, and the precise matching of the motor and pump body enhances overall operating efficiency. This means that under the same operating conditions, these pump units can achieve higher water supply efficiency with lower energy consumption, reducing operating costs while also aligning with current trends in green energy conservation and environmental protection. Long life and low maintenance requirements further enhance the value of vertical in-line fire pumps. Their compact design, minimal component wear, and corrosion-resistant materials and high-strength seals ensure reliability and durability even in high humidity or challenging environments. This stable operation reduces equipment downtime and maintenance costs, helping users achieve long-term economic benefits. Ease of installation and maintenance are also key factors in choosing vertical in-line fire pumps. Their vertical structure allows the pump to connect directly to the pipeline, eliminating the need for additional foundations and extensive piping modifications, significantly shortening the installation period. Furthermore, easy disassembly and assembly of the pump and replacement of parts ensure rapid system restoration even in emergencies. The trend toward intelligentization is also driving the application and upgrading of vertical in-line fire pumps. Equipped with advanced automatic control systems, these pump units offer automatic start-stop, pressure monitoring, fault alarms, and remote monitoring, making them more efficient and reliable in responding to fire emergencies. For high-rise buildings and underground projects requiring 24/7 protection, intelligent features allow managers to monitor equipment operating status at all times, further enhancing system safety. Flexible application scenarios are a key feature of vertical in-line fire pumps. Whether it is used in high-rise residential buildings, office buildings, commercial complexes, or in complex scenarios such as subways, tunnels, and underground garages, this pump unit can meet different water supply needs according to local conditions. Its diverse specifications and models allow users to flexibly choose according to the scale and needs of the project, ensuring the scientific and rational configuration of the system. In summary, the vertical pipeline fire pump has become a reliable guardian in the fire protection system of high-rise buildings and underground projects with its many advantages such as compact design, stable performance, high efficiency and energy saving, long life, low maintenance and intelligent control. In the face of complex and changing fire risks, it can provide solid safety guarantees for buildings with its efficient water supply capacity and reliable operating status. With the acceleration of urbanization and the continuous improvement of safety standards, vertical pipeline fire pumps will undoubtedly play a more important role in future fire protection applications and become an indispensable core equipment to ensure public safety and stable building operations.

.jpg)