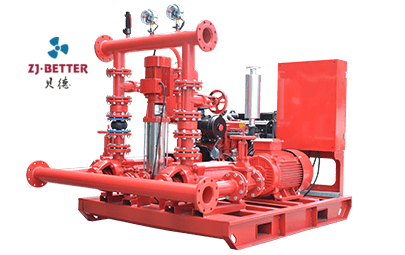

Fully Automatic Pressure-Maintaining Fire Pump System: Dual Assurance of Rapid Response and Continuous Water Supply

The fully automatic pressure-maintaining fire pump system is designed to meet the urgent water supply needs in firefighting scenarios by integrating advanced pump technology with intelligent control systems. Its unique pressure stabilization mechanism rapidly adjusts the system pressure at startup, ensuring that sufficient water pressure is available during the early stages of a fire. The automated control module offers round-the-clock intelligent monitoring and self-diagnosis, guaranteeing stable and efficient operation under extreme conditions. With a compact and modular design that simplifies installation and maintenance, this system is ideal for high-rise buildings, underground garages, industrial parks, and other locations where continuous fire water supply is critical. The system not only significantly improves firefighting efficiency but also reduces operational costs, making it the ideal solution for building modern, intelligent fire protection systems.

In an era of continuous innovation in fire safety, this enterprise is dedicated to developing and manufacturing a diverse range of fire pump systems and associated equipment to meet the ever-growing demand for emergency water supply. Backed by precision engineering, the company has integrated cutting-edge intelligent control, modular design, and energy-saving technologies to deliver solutions that incorporate various power sources—from electric to diesel drives. Its product portfolio includes fully automatic fire pump sets, pressure stabilizing devices, and remote monitoring control panels, widely employed in high-rise buildings, industrial parks, transportation hubs, and urban public facilities. With a rigorous quality management system and adherence to international certification standards, the company continuously enhances product performance to ensure rapid response and long-lasting reliability under extreme conditions, thereby providing robust support for building an efficient and sustainable fire protection network.