The main components of the fire pump

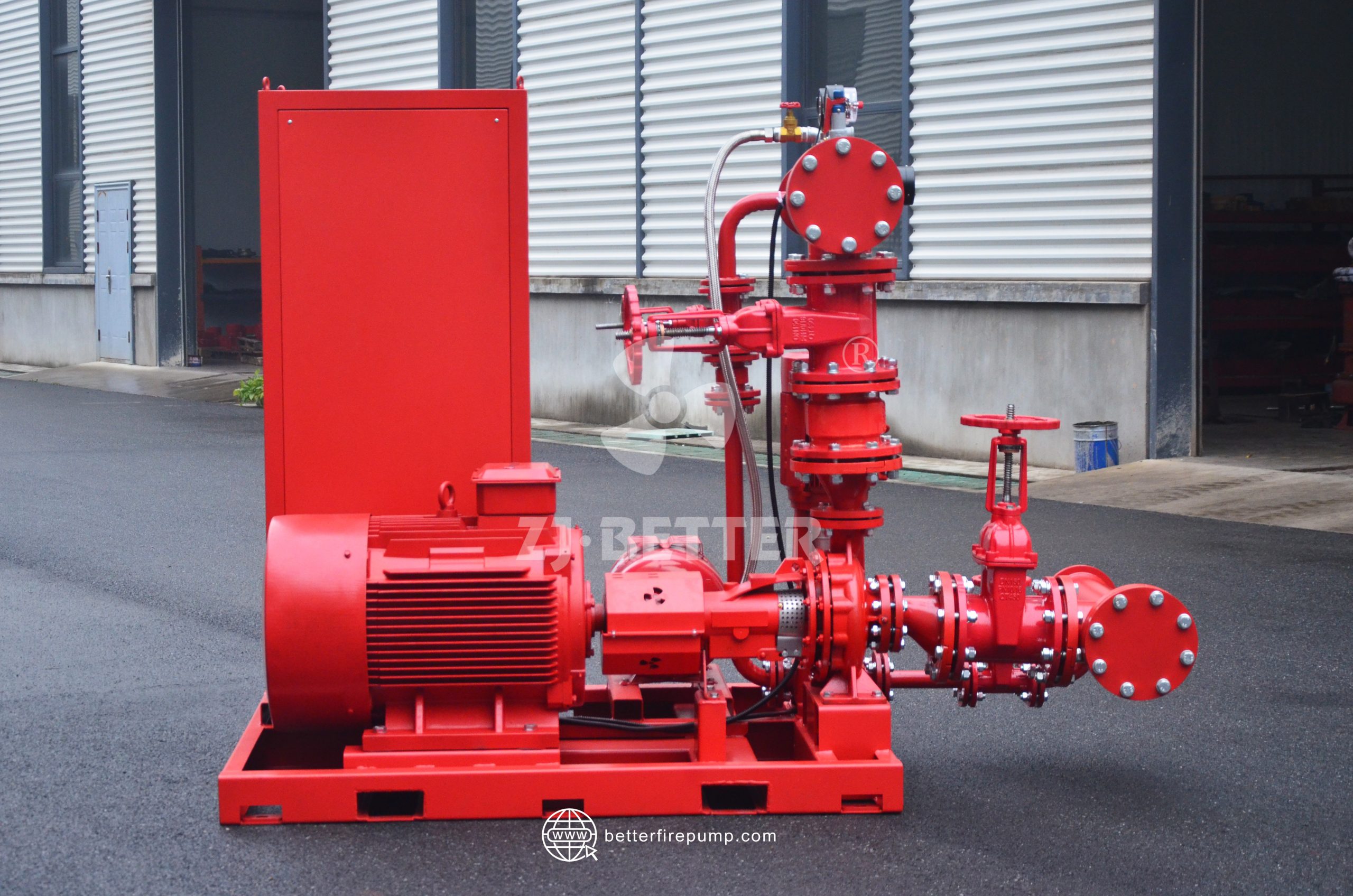

1. Fire Pump: A fire pump is the heart of a fire sprinkler system and is used to create the necessary water pressure to make the system work. It is powered by an electric motor or diesel engine and pumps water from a water source to the sprinkler system.

2. Control Panel: The control panel is the brains of the fire sprinkler system. It controls the flow of power to the pump and monitors the sprinkler system for any changes in pressure or water flow. It also triggers alarms and other safety devices in the event of a fire.

3. Suction Pipe: The suction pipe is connected to the fire pump and draws water from the water source. It is usually made of steel and must be strong enough to withstand the pressure exerted by the pump.

4. Pressure Gauge: The pressure gauge is used to measure the pressure in the system and ensure that the pump is providing the correct amount of water pressure. It is usually mounted on the control panel.

5. Valves: Valves are used to control the flow of water to and from the system. They are typically operated manually or automatically and can be used to start and stop the pump, control the flow of water, and isolate parts of the system for maintenance.

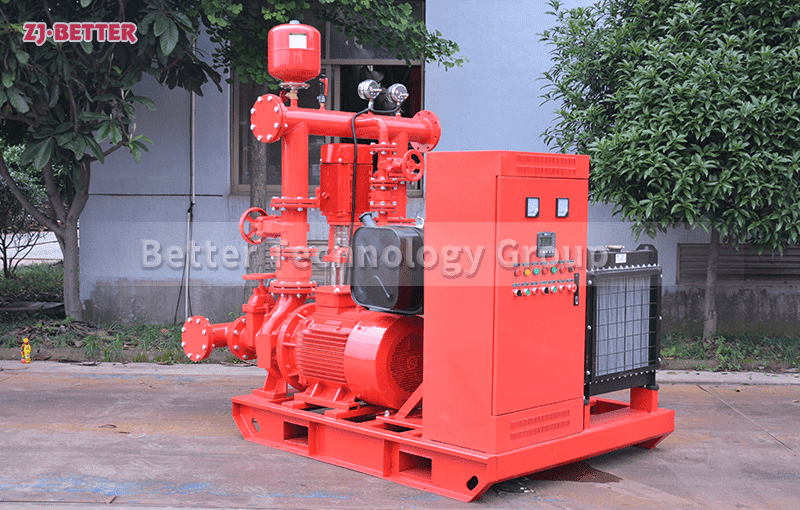

1. Fire Pump: A fire pump is the heart of a fire sprinkler system and is used to create the necessary water pressure to make the system work. It is powered by an electric motor or diesel engine and pumps water from a water source to the sprinkler system.

2. Control Panel: The control panel is the brains of the fire sprinkler system. It controls the flow of power to the pump and monitors the sprinkler system for any changes in pressure or water flow. It also triggers alarms and other safety devices in the event of a fire.

3. Suction Pipe: The suction pipe is connected to the fire pump and draws water from the water source. It is usually made of steel and must be strong enough to withstand the pressure exerted by the pump.

4. Pressure Gauge: The pressure gauge is used to measure the pressure in the system and ensure that the pump is providing the correct amount of water pressure. It is usually mounted on the control panel.

5. Valves: Valves are used to control the flow of water to and from the system. They are typically operated manually or automatically and can be used to start and stop the pump, control the flow of water, and isolate parts of the system for maintenance.