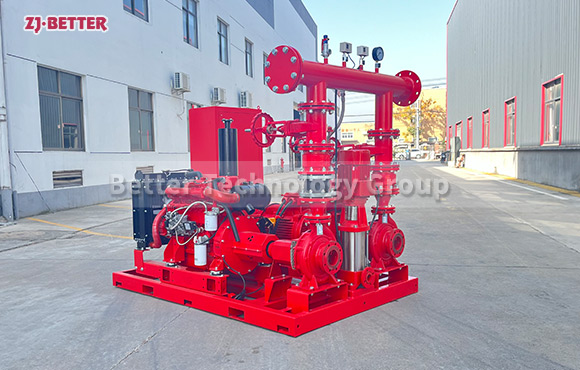

Electric Motor-Driven End Suction Fire Pump System for Reliable Emergency Response

Discover the reliability and efficiency of electric motor-driven end suction fire pump systems. Designed for high performance, compact installation, and easy maintenance, they ensure rapid emergency response and meet international fire safety standards for commercial and industrial applications.

The electric motor-driven end suction fire pump system stands at the forefront of modern fire protection technology, offering unmatched performance, reliability, and efficiency for emergency response in commercial, industrial, and municipal applications. Designed with precision engineering, this type of fire pump utilizes a horizontal, end-suction centrifugal configuration, which is one of the most trusted designs in the fire protection industry due to its simplicity, compact size, and efficient hydraulic characteristics. The pump features a direct-coupled, robust electric motor as its primary drive source, providing stable power output with minimal vibration and low noise levels. The motor is built to conform to international standards such as IEC or NEMA, ensuring compatibility with a wide range of control systems and power supply networks. One of the key advantages of the end suction fire pump system is its exceptional space efficiency, making it ideal for installation in confined pump rooms or retrofit projects where floor space is limited. Its streamlined design facilitates easier alignment between the pump and motor, reducing installation time and maintenance requirements. This pump is specifically designed to meet or exceed the stringent standards of NFPA 20, UL, and FM when applicable, ensuring consistent and dependable performance in life-safety systems. The pump casing is typically constructed from cast iron or ductile iron, with options for stainless steel or bronze impellers, providing excellent corrosion resistance and durability in various environmental conditions. Its impeller is dynamically balanced to minimize wear and ensure smooth operation, while the mechanical seal and bearings are selected for long service life under continuous duty conditions. The system is engineered to deliver high flow rates and stable pressure curves, which are critical in maintaining adequate water delivery during high-demand fire scenarios. In the event of a fire emergency, this pump system is capable of immediate start-up, offering rapid water flow to sprinkler heads, standpipe systems, or hydrant outlets with minimal delay. Control panels supplied with the unit include user-friendly interfaces, LED indicators, automatic start functions, pressure sensors, alarm displays, and manual override capabilities. Optional features such as soft starters, variable frequency drives (VFDs), and remote monitoring modules can be integrated to provide energy savings, protect the motor from power surges, and enable off-site diagnostics or control. These systems are available in a wide range of flow capacities—commonly from 50 GPM to over 2000 GPM—and can handle discharge pressures suitable for both low-rise and high-rise buildings. Their flexibility allows them to be configured for single-pump or multi-pump operations, including jockey pumps and diesel backup units, ensuring redundancy and uninterrupted fire protection in mission-critical facilities. The pump and motor assembly is skid-mounted, often pre-piped and pre-wired, simplifying field installation and reducing on-site labor costs. Each system undergoes rigorous testing at the factory, including hydrostatic pressure testing, performance curve verification, and electrical integrity checks, to guarantee field readiness and compliance with relevant codes. Additionally, the motor-driven configuration is favored in jurisdictions where diesel fuel storage is restricted or emissions regulations are tight, offering a clean, quiet, and maintenance-friendly alternative. These pumps are suitable for integration into building management systems (BMS) and fire alarm networks, enhancing automation and ensuring that any fault, pressure drop, or start-up condition can be communicated instantly to control centers. With increasing emphasis on sustainable infrastructure, the electric motor-driven fire pump offers a more environmentally friendly solution by consuming less energy during stand-by and delivering peak performance only when activated. Furthermore, modern designs incorporate water-saving technology and motor efficiency classes such as IE3 or IE4, reducing operational costs over the product’s life cycle. The system’s components are engineered for easy replacement and service, with wear parts such as seals and bearings accessible without disassembling the entire pump body. Maintenance intervals are typically longer than with diesel units, and the absence of fuel management requirements simplifies compliance with local codes. The reliability of these systems is further enhanced by built-in redundancy protocols, such as dual controllers or auto-transfer switches when used in dual-power configurations. Whether installed in commercial buildings, factories, airports, power stations, or warehouses, electric motor-driven end suction fire pump systems offer peace of mind, operational efficiency, and robust protection against fire hazards. Their low total cost of ownership, ease of integration with modern infrastructure, and ability to support smart building technologies make them the preferred choice for engineers, contractors, and facility managers worldwide. With customizable options such as horizontal or vertical mount, flanged or threaded connections, and optional corrosion-resistant coatings, these systems can be tailored to meet specific client or project needs. The unmatched durability, high performance under pressure, and compliance with global fire safety norms ensure that electric motor-driven end suction fire pumps remain an essential component in every fire suppression strategy. Their silent operation and zero emissions make them ideal for use in hospitals, schools, hotels, and other noise-sensitive environments. Moreover, their proven reliability under extreme weather conditions and in seismic zones further supports their application in critical infrastructure projects. Designed for longevity, safety, and seamless operation, this fire pump system continues to evolve with smart diagnostics, predictive maintenance analytics, and IoT-based monitoring tools, pushing the boundaries of what fire protection equipment can achieve in the age of intelligent automation.