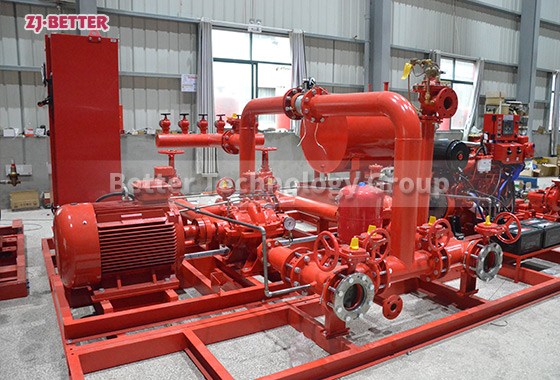

Horizontal EDJ Fire Pump System Electric Diesel Booster Pump With Controller Fire Pump Set

Application areas: commercial, municipal and residential high-rise buildings, large industrial plants and warehouses, offshore and remote facilities, airports, power stations.

Industrial fields: various petroleum, petrochemical, chemical, oil fields, management bureaus, oil depots, oil terminals, oil refineries, offshore platforms, etc.; national grain depots, thermal power plants, steel mills, shipyards, paper mills, etc.;

Commercial fields: five-star hotels, hospitals, schools, supermarkets, office buildings, large commercial complexes, highway tunnels, subway stations, railway stations, airports; fire engineering companies;

The main pump can be an end suction pump, multistage pump, split pump or vertical turbine pump and is standard in stainless steel, cast iron and bronze.

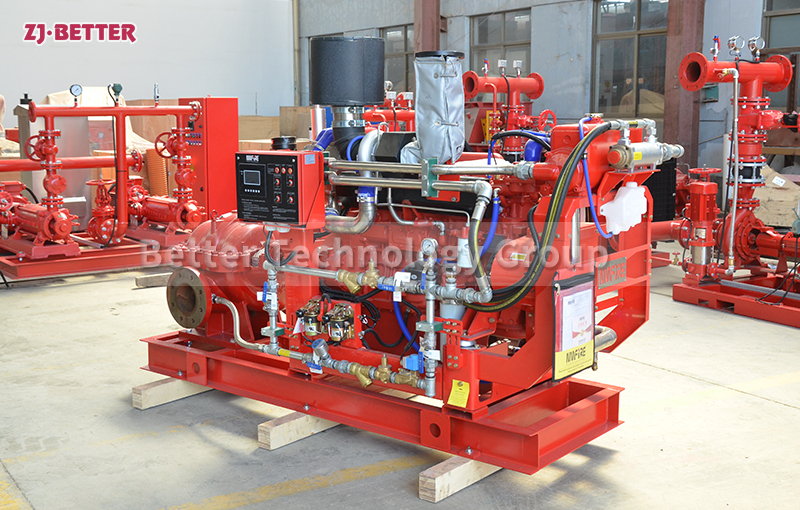

Each package is mounted on a steel base where the motor, motor and pump are connected and wired to the controller. Automatic bleed valves, gate valves, check valves, flexible joints, pressure switches and pressure gauges are installed on their respective pipelines. Additional piping, pressure tanks, valves and sensing lines can also be provided if required.

The Fire Pump Control Panel is the brain of the pump system, designed to control and monitor the operation of electric, diesel and pipeline pump drives, and to compose pumps for manual and automatic modes, as well as to switch the pump drive on/off under specific conditions.

The fire pump pack controller detects the signal through a set of built-in pressure switches that reflect the system pressure and flow status, enabling the fire pump pack driver (electric/diesel/Jockey) to operate when the system pressure is below the set point, such as As well as operating a spare drive due to power failure and/or a significant drop in pressure.