How does the automatic monitoring and alarm system enhance the safety of operations?

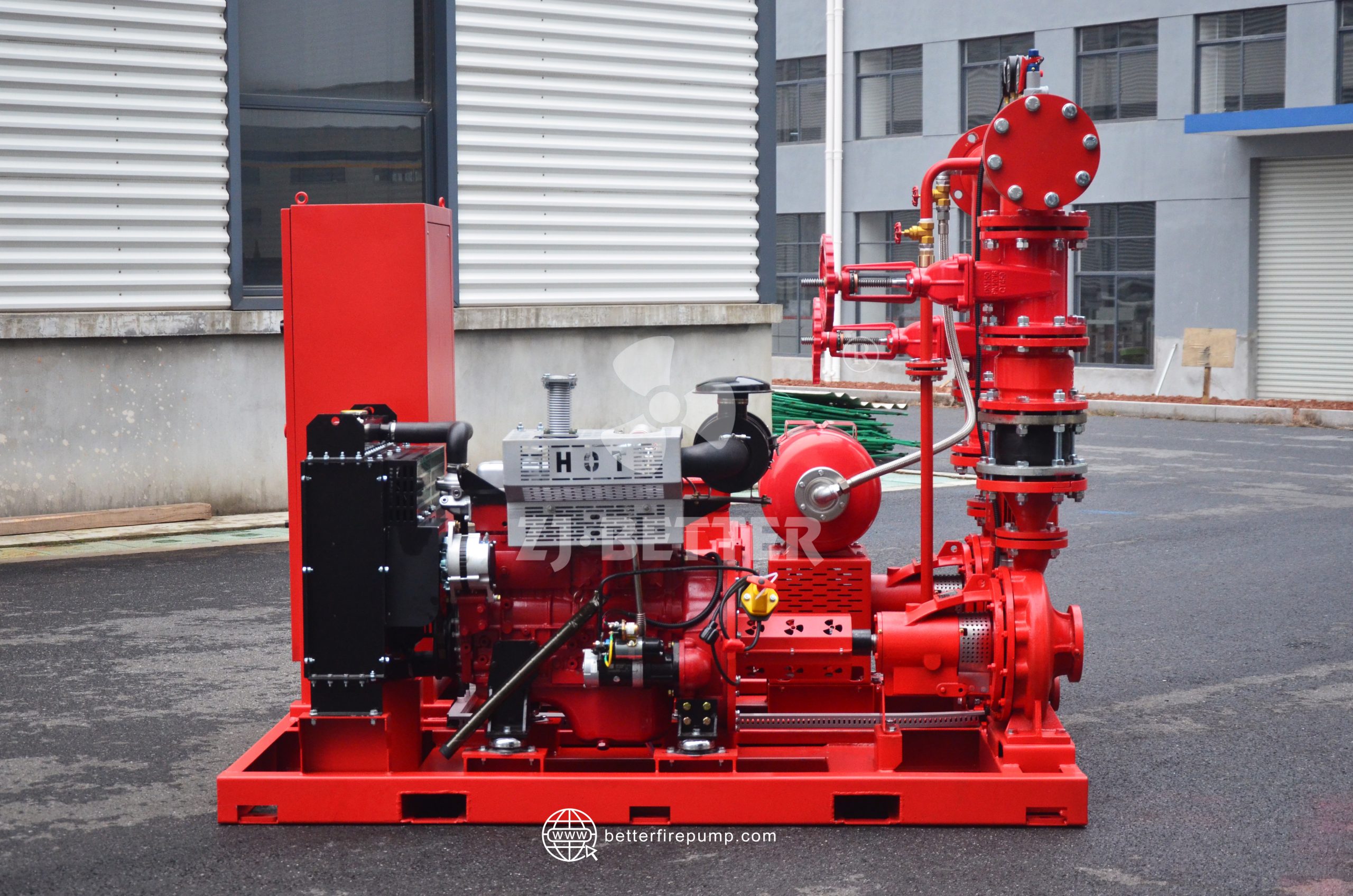

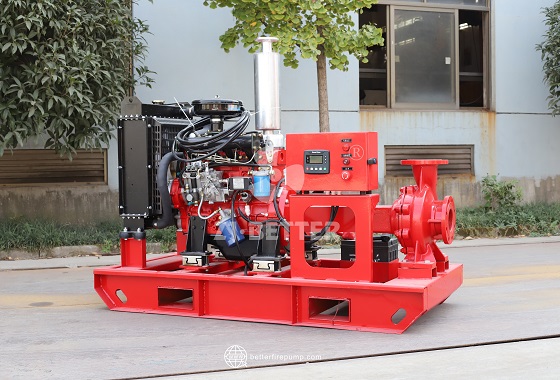

This fire pump is equipped with an automatic monitoring and alarm system, which allows real-time monitoring of the pump’s operational status and sends timely alerts in case of any abnormalities. Users are immediately notified of any issues, enabling them to take appropriate action in the shortest possible time. This significantly enhances operational safety and effectively reduces the risk of equipment failure. The introduction of an intelligent control system ensures that the pump automatically starts when needed and maintains efficient operation, guaranteeing the reliability and timely response of the fire protection system. Additionally, the high-performance design and durability of this fire pump ensure stable performance in various environments, providing sustained, efficient water supply over extended periods.

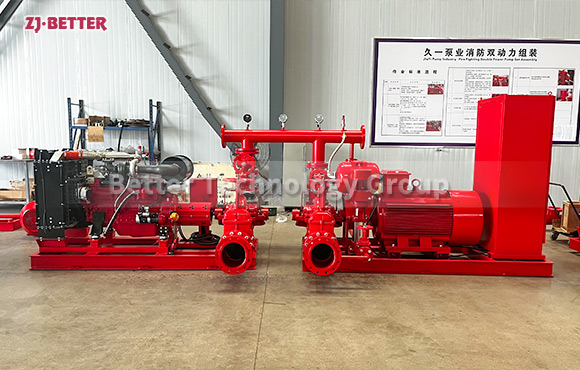

Our company specializes in the research and production of high-performance fire pump systems, dedicated to providing safe, efficient, and reliable fire protection solutions for various industries. Our product range includes electric fire pumps, diesel engine fire pumps, and pressure-stabilizing water supply systems, which are widely used in high-rise buildings, industrial parks, commercial complexes, petrochemical industries, and more. Each product is designed with advanced concepts to ensure high head, large flow output, meeting different fire protection requirements. Our fire pumps are equipped with intelligent control systems that feature automatic start-stop, fault monitoring, and remote monitoring, enhancing operational safety and convenience. With high-temperature and corrosion-resistant materials, the equipment is designed to remain stable and reliable in harsh environments. All of our products comply with UL, NFPA, and other international fire safety standards, ensuring comprehensive fire protection for our customers.