Tailored for Critical Scenarios: Application of Vertical Shaft Pumps in Petrochemical Plants, Power Stations & Ports

Vertical long shaft pumps deliver high head, continuous performance, and corrosion resistance, making them ideal for petrochemical, power plant, and port applications. Perfect for deep well supply, cooling circulation, and fire protection in demanding industrial environments.

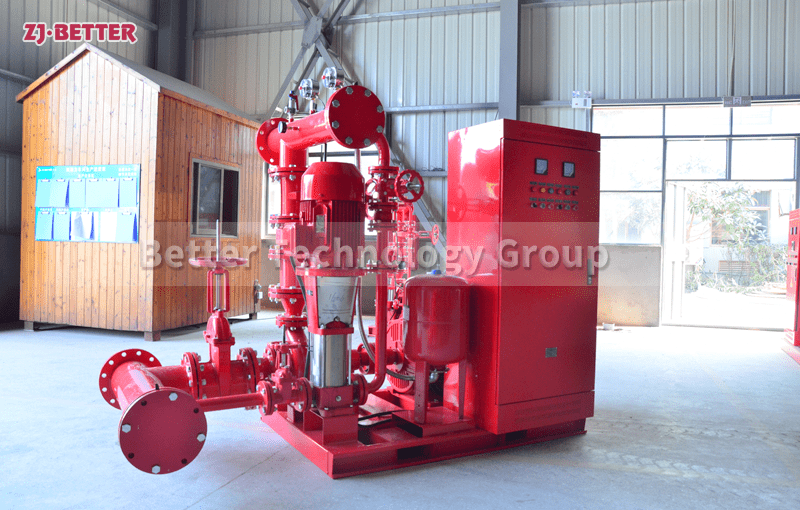

In today’s industrial water supply and fire protection systems, the vertical long shaft pump has become an indispensable solution in demanding applications due to its high head performance, excellent continuous operation, and structural reliability. Particularly in petrochemical plants, power stations, seaport fire protection systems, and large water treatment facilities, this pump type outperforms traditional horizontal or submersible pumps, offering unmatched reliability and efficiency in lifting water from deep sources to the ground system.

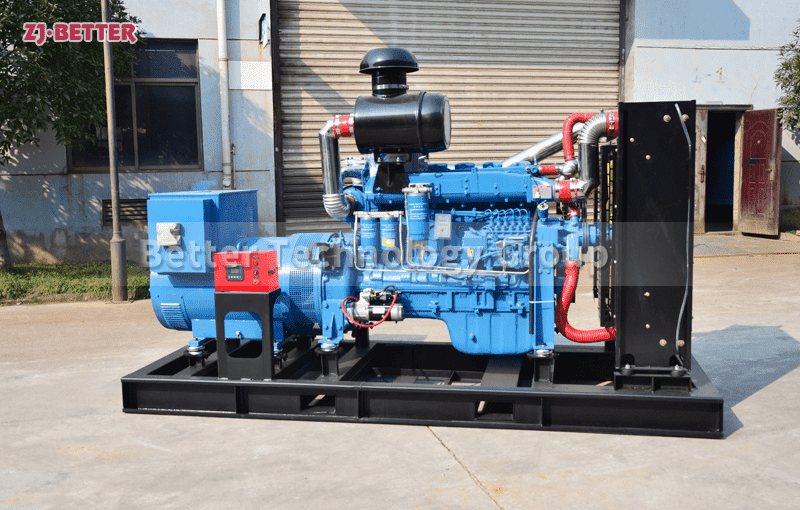

Comprising a motor, coupling, column pipe, intermediate shaft, line shaft bearings, water-lubricated bearings, and a submerged pump bowl assembly, the vertical long shaft pump’s vertical configuration saves installation space and makes it ideal for deep wells, sump pits, and reservoirs. In hazardous areas such as oil terminals and seaports, it can be equipped with explosion-proof motors, anti-corrosion materials, and intelligent control systems to ensure safe and reliable 24/7 operation.

In the petrochemical sector, these pumps are often used for transferring corrosive liquids, cooling water, or as part of emergency fire water supply systems. With components made of 316L stainless steel or duplex steel, they withstand harsh chemical environments and high temperatures. In power generation, particularly for circulating cooling water and boiler feed systems, the vertical long shaft pump provides large flow capacities with minimal vibration, enhancing system reliability while reducing maintenance costs. In port facilities, where fluctuating tidal levels pose challenges, the modular shaft design with multiple line bearings allows customization to specific well depths, ensuring continuous and stable water extraction.

Furthermore, vertical shaft pumps support a wide range of customization options, including dry or wet motor configurations and shaft lengths ranging from 2 to 30 meters, suitable for deep wells, tanks, or open water sources. They feature smooth startup, low noise levels, and extended service intervals, making them ideal for continuous industrial use. When integrated with advanced PLC systems, these pumps support remote control, water level detection, real-time alerts, and historical data tracking, significantly enhancing automation and operational efficiency.

As smart industry and urban infrastructure continue to evolve, the vertical long shaft pump is finding new ground across diverse applications. Whether in handling aggressive chemical fluids, operating under high-temperature high-pressure conditions, or coping with dynamic water levels in port and shipyard environments, this pump delivers a stable, safe, and high-efficiency fluid transport solution. Looking forward, it will continue to be a pivotal component in advanced fluid management systems across critical industries.